Lynxter announced a new direct drive toolhead, the FIL21.

Direct drive extruders are definitely not new in the world of 3D printing; in fact that approach was the first used when FFF 3D printers were invented decades ago.

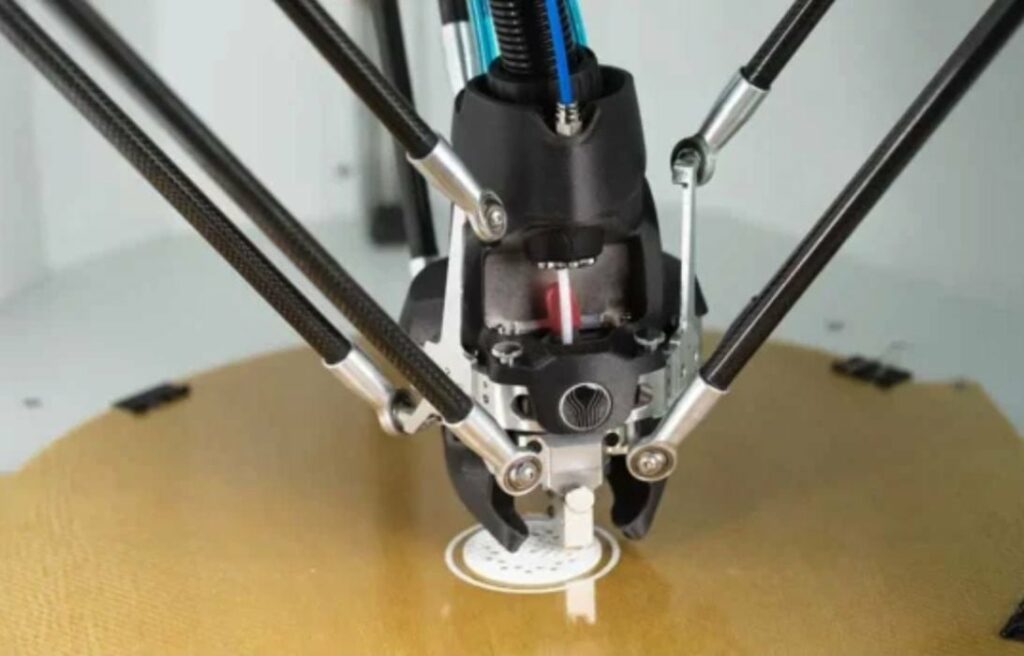

The difference here is that the FIL21 is designed to fit onto Lynxter’s flagship 3D printer, the S600D. The S600D is a delta 3D printer, quite different from the typical cartesian systems.

Normally delta-style 3D printers use Bowden extruders, where the filament is pushed externally towards the hot end. This is done to lower the weight of the moving toolhead and presumably enable faster 3D printing.

However, Bowden equipment comes with other caveats: they are generally terrible when handling flexible filaments, because they tend to fold up in the tube when being pushed forward. There are also challenges with high-ratio metal infused filaments, which don’t bend easily in the Bowden tubes. As a result, you don’t see a lot of flexible 3D printing on delta equipment.

The Lynxter S600D 3D printer is a very unusual machine. The company calls it a “universal 3D printer”, and they’re not wrong: the device has interchangeable quick-swap toolheads that can handle a very wide variety of materials.

This means a single S600D can 3D print a wide selection of polymers, liquids (like silicone), ceramic pastes, and much more. Here is a list of their current extruder options and the materials enabled by them:

- FIL11 — PP, PEKK, PETG, PA Carbon Fiber, PC, TPU 85 ShoreA, ABS Carbon

- FIL33 — ABS Carbon Fiber, ABS-ESD, ABS-PC, PC, PET, PETG Carbon Fiber, PLA

- LIQ11 — Silicone RTV 34 ShoreA, Silicone RTV1 57 ShoreA

- LIQ21 — Silicone RTV2 40 ShoreA, Silicone RTV2 25 ShoreA

- PAS11 — Alumina, Cordierite, Zirconia, Clay, Stoneware, Porcelain

And now added to that list is the new FIL21, which handles Alumina, Zirconia, 316L, TPU, TPE, TPC, PETG Carbon Fiber and PLA. In fact, the FIL21 has a maximum extrusion temperature of 450C, making it feasible to print a wide variety of engineering and high temperature materials on the S600D.

Lynxter explains:

“The FIL21 can print wider and denser layers, which leads to a reduction in the number of printing layers and thus to additional time savings. 3D printing is precise, fast, and easy.”

The S600D includes a fully heated build chamber and it’s also equipped with a HEPA filtration system to eliminate odors.

All this happens within a large cylindrical build volume of 390 mm diameter and 600 mm tall, making it possible to build large parts in an incredible varied set of materials.

If you’re looking for a professional 3D printer that can handle the widest possible variety of materials, the S600D should be on your list of options — and it just got a lot better.

Via Lynxter