In an incredible experiment, researchers were able to simulate the molecular behavior of 3D printing resins.

Specifically, the researchers at Lawrence Livermore National Laboratory (LLNL) were able to examine the molecular bonding of several acrylate resins.

Acrylates are typically used in commonly available photopolymer resins. These have the unique property of solidifying when exposed to specific frequencies of light energy. In a resin 3D printer, this is done with lasers, LEDs or projectors.

In their paper, ”On the Network Topology of Crosslinked Acrylate Photopolymers: A Molecular Dynamics Case Study”, the researchers say:

“By employing the same force field and reactive scheme and studying three representative multifunctional acrylate monomers we isolate the importance of the nonreactive moieties within these model monomers. Analyses of reactive trajectories benchmark the estimated gel points, cyclomatic character, and spatially-resolved crosslinking tendencies of the acrylates as a function of conversion. These insights into the similarities and differences of the polymerization and resulting networks suggest molecular mechanics as a useful tool in the rational design of photopolymerization resins.”

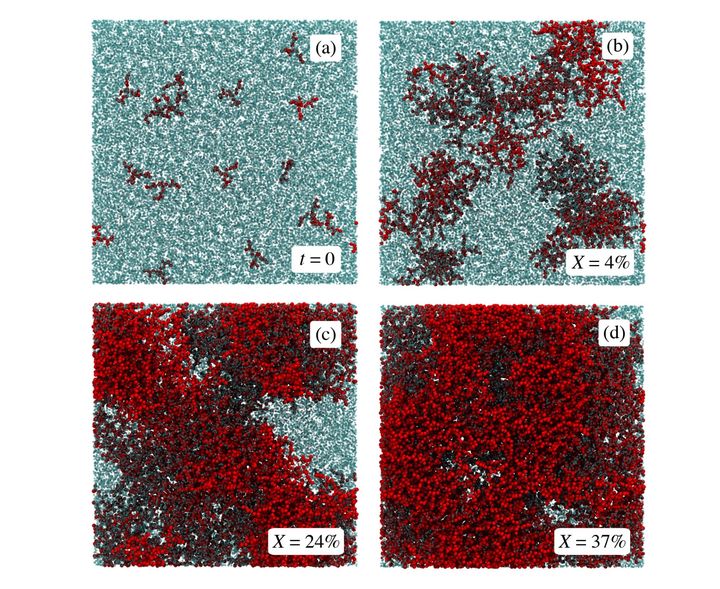

They’re using advanced particle dynamic simulation methods to observe how a given chemical formula will react. Their simulation involved a virtual cube of monomers of either 512 or 2000 “molecules”. This complex process involved simulating local ordering, structure and dynamics of each monomer as it polymerized.

At top you can see an image of the simulated polymerization that took place. In the time sequence, the blue liquid resin gradually polymerizes into red material.

I believe this be a significant breakthrough for the 3D printing industry, as it opens the door for the development of incredibly more powerful resin materials.

Essentially they’ve developed a way to computationally design and test potential resin materials. This could be vastly more efficient than physical experimentation.

Imagine a future system in which you provide some input parameters of the desired resin and then you let the machine churn through endless possibilities to eventually identify a chemical formula that meets those requirements.

That’s astounding!

If this type of system were to become available there might be a tidal wave of customized resins with all manner of unusual properties suddenly available.

That could greatly assist the development of new 3D printing processes that are based on resin materials. One that specifically comes to mind is volumetric 3D printing, a new approach in which a cylindrical vat of clear resin is transformed into the desired object all at once. This startling technology is not yet available, but several parties are deep at work on it.

It’s quite likely their approaches could be helped or even enabled by a simulated resin formula that optimizes for their requirements.

We may see not only new resins, but new 3D printing processes emerge as a result of this research.

Via ACS