Markforged announced a very useful new feature for their Eiger software platform.

Markforged produces several types of 3D printing equipment for professionals and industry to make strong parts, either with metal, continuous carbon fiber or strong engineering polymers. To power those devices, the company also provides Eiger, their job preparation software tool.

Job prep software is commonplace in the industry, it’s required for all 3D printers. Some companies simply rely on open source slicing tools for this function, while others, like Markforged, produce their own platforms.

Markforged’s platform is “Eiger”, and it performs the functions you’d expect from a slicer.

Let’s step back a bit and look at what seems to have led up to this point.

Teton Simulation produced an amazing slicer plug-in called “SmartSlice”, which essentially merges slicing and simulation together. Slicing is the function that generates the GCODE to execute on a 3D printer, while simulation is a mathematical process of visualizing how a part will react under specified stresses, mechanical and otherwise.

This combination enabled SmartSlice operators the ability to generate unusual GCODE toolpaths that would strengthen areas of the print that required more according to the simulation analysis. Basically, you get better parts that would almost always function as intended, automatically.

Teton Simulation marketed the product as a plug-in to existing slicing software tools. For example, their first software deployment was to Ultimaker Cura, via that software’s plug-in library. Users could subscribe to SmartSlice and use the product within a slicer they were familiar with, and get “intelligent” slicing.

Other partnerships followed.

Then Markforged acquired Teton Simulation.

At the time I wondered how this would play out, as Teton Simulation was providing their software to other companies in the space, some of which could potentially be competing with Markforged. Those companies included Stratasys, BCN3D, BigRep and others.

Now we know a little bit more. Markforged announced they’ve integrated “new simulation features” into Eiger, which are no doubt some version or adaptation of SmartSlice.

Markforged explains:

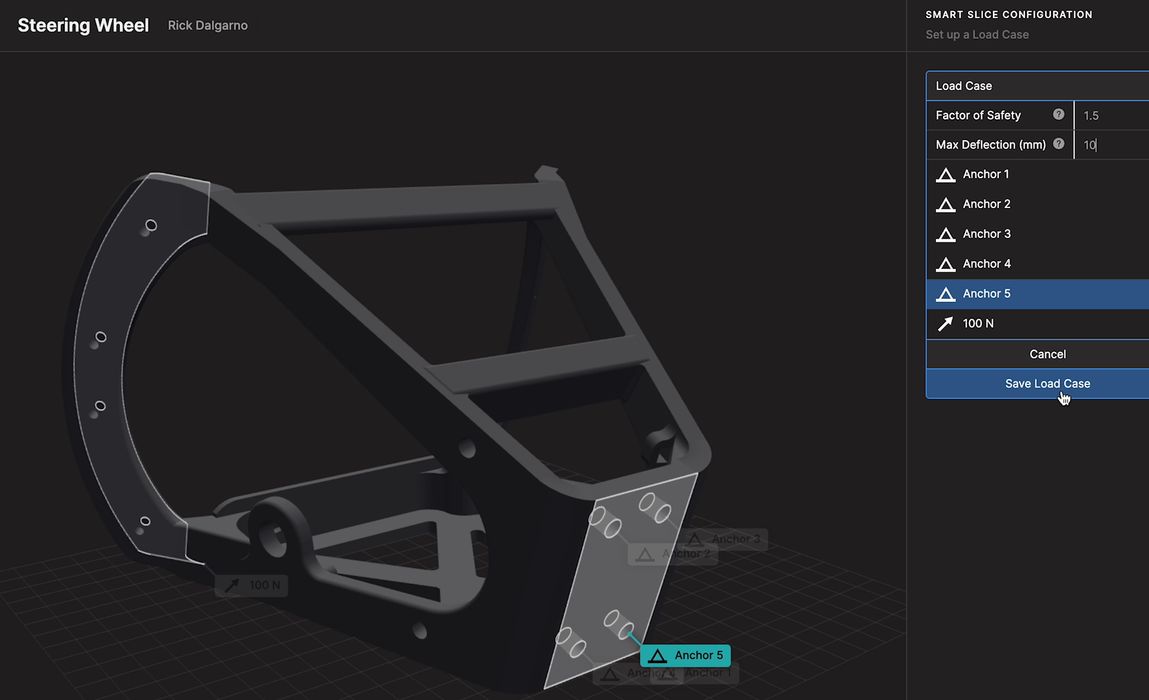

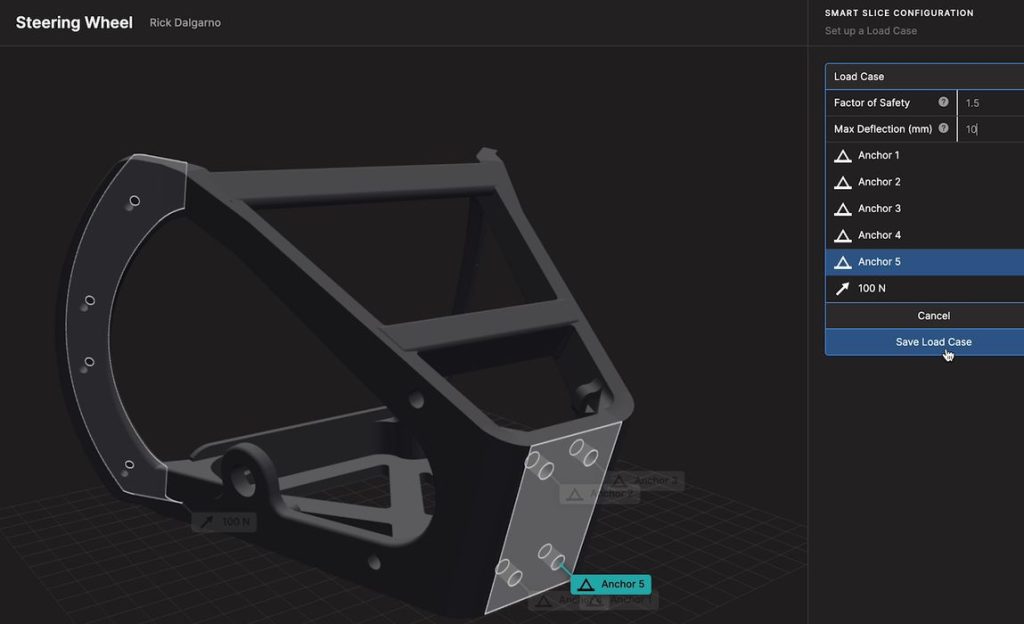

“Unlike traditional software tools that need specialized expertise and time-consuming analysis, Simulation is designed for additive manufacturing and works within the familiar Eiger software slice and print workflow. Any user can validate part strength and stiffness through virtual testing by identifying anchor and load surfaces and then entering values for loads, factor of safety and maximum deflection. They can then optimize parts by automatically determining print settings for floors, walls, infill and fiber reinforcement to achieve print cost and speed goals while maintaining adequate strength.”

The benefit to Eiger users is that they can now leverage simulation to generate better toolpaths and thus better quality parts.

In other words, Markforged appears to have now integrated SmartSlice functionality into Eiger, and that’s great news for Markforged clients. They will now be able to make far better parts with the same equipment they use today.

The concept of mixing simulation and slicing is quite new to most people, as the only folks familiar would be SmartSlice subscribers. To break the ice with clients, Markforged has now provided EVERY Eiger user with a free trial of the simulation features until April 2023 — that’s half a year to get accustomed to using advanced slicing technology.

After April, Eiger users will require a paid subscription.

Via Markforged