An Israeli company uses an unusual 3D printing process to make large-scale objects.

Largix, founded in 2015, has developed a process they call “APS”, for “Additive Production System”. The process appears suitable for producing larger-sized objects with straightforward geometry.

How does it work? It’s quite unusual, but seems like a combination of FFF and WAM.

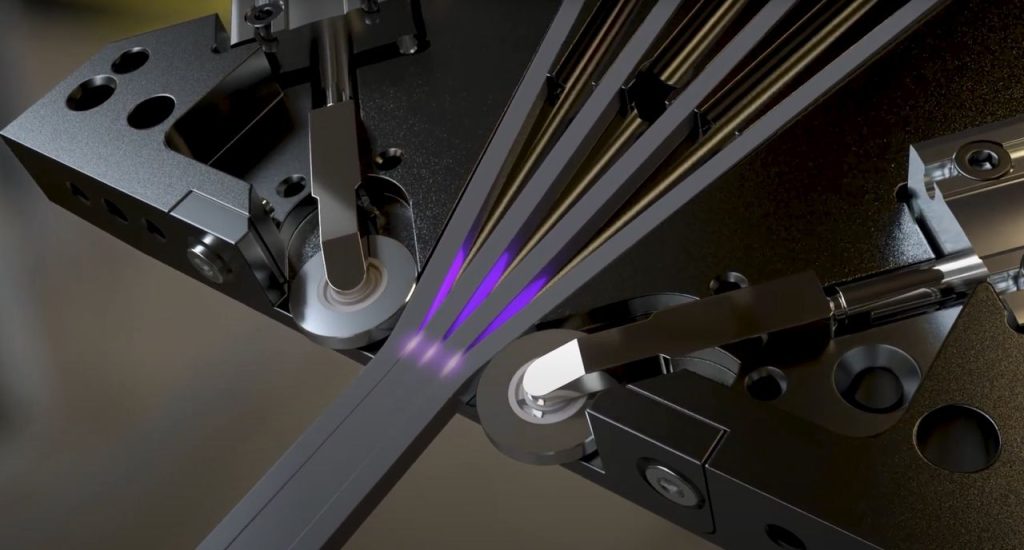

There are multiple materials fed into the extruder, as seen in this image. As the materials come together, a laser rapidly melts the surfaces of the materials, so that the roller can press them together into a unified, thick, extrusion.

This thickened material is then laid down and fused onto previously deposited layers with a laser system as seen in this image.

By moving the toolhead around, it’s possible to create large objects. Imagine, for example, a large chemical storage tank produced in this way. It would be similar in concept to “vase mode” as is found on some desktop 3D printer software, but here the walls would be extraordinarily strong due to the multiple filaments involved.

The materials used appear to be polypropylene and polyethylene, but I suspect APS could be made compatible with a variety of other thermoplastics and composite materials.

Largix indicates they have an addressable market of US$100B. That may seem large, considering the APS technology may have a narrower set of applications than some other 3D print technologies. However, markets for simple objects such as storage tanks are quite large and worldwide. In addition, these large parts are expensive to make, but straightforward for a technology like APS.

The ability to create custom products of this type could be quite advantageous for certain industries. Largix believes they can reduce production costs by around 50%, which is significant.

Another interesting aspect of APS is that in theory it could be used to produce the large parts on site, rather than doing so at a factory and shipping them. For large objects, shipping can be a complex and expensive matter, or even impossible in some situations.

For Largix, storage tanks seems to be their first industrial application, but the company also believes they can address needs in other industries, including aerospace.

The aerospace industry has long been a leader in use of additive technologies, so they may be a prime market for APS. On the other hand, many of their parts require significant certifications and regulatory process, which is something that Largix would have to undertake.

APS is one of those quiet additive technologies that could make a big impact in very specific industries.

Via Largix