Matter and Form have launched a new and powerful metrology-grade 3D scanner called “Three”.

We first saw the Toronto-based company way back in 2015 at CES, where they had launched a tabletop 3D scanning system two years earlier in 2013. Since then the company has been incrementally developing new versions of their scanning technology, culminating in their latest device, the Three.

[I’m unsure whether it’s called “The Three” or just “Three”, so we’ll go with “Three”]

Over that ten year span they’ve learned a considerable amount about 3D scanning, particularly due to their work with customers to understand what’s actually required in a scanner.

Three is a structured light device, but a significantly powerful one. It uses a high resolution DLP projector to display patterns on the object surface, and twin 13MPx cameras to collect scan images.

Three seems to be usable in several operational scenarios. For example, it can be used as a tabletop 3D scanner, where a turntable rotates a small object in front of the scanner.

However, it can also be used to scan large objects that would not fit on a turntable. How large, exactly? It seems there is no limitation. Their product video shows an entire automobile being scanned.

But how is this done? Typically portable 3D scanners would capture a number of automobile sections, and then the operator would have to precisely knit them together in software later. I find this “stitching” process to be the most tedious part of 3D scanning, as it often creates issues.

However, it appears that Matter and Form have realized this and have equipped Three with the ability to automatically stitch segments together! This is a significant feature that is not available on most other 3D scanners, and it should make scanning larger objects extremely straightforward.

They say the device can capture geometry to an accuracy of 0.05mm, which is quite impressive.

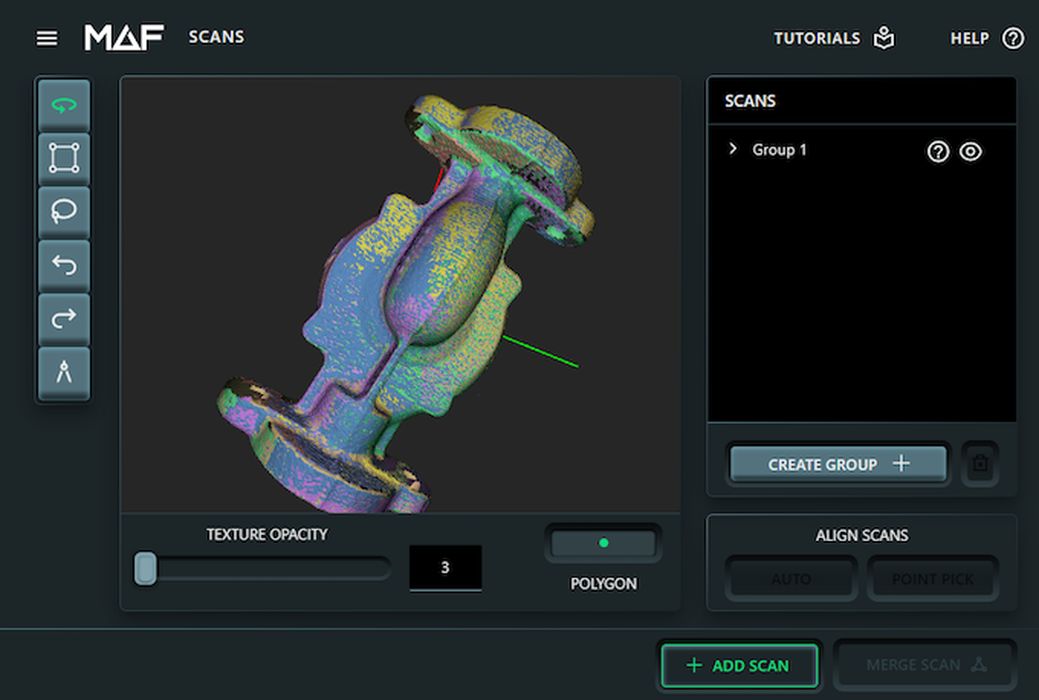

Even more impressive is the software, which performs much of the work automatically, unlike other systems.

Interestingly, the software runs on the device and is presented to the operator as a web page. Basically you connect your device — a laptop or even a tablet — to the device’s WiFi to see these web pages.

That’s an amazing feature in itself, because many 3D scanning systems require very hefty PC hardware to run, and usually they’re attached with an unwieldy thick cable that you will inevitably trip over.

Note that while the data is presented via web page, there are no subscriptions required. It seems to be entirely processed locally.

Matter and Form have included a new algorithm they call “ChromaSpec”. This processing enables the scanner to “detect and process different colored areas of the object”. That’s quite different from most 3D scanners that employ only a single light frequency during scanning. That should enable Three to capture a bit more detail.

Another unusual feature is an API that allows operators to develop their own code for vision projects and run them on the Three platform. They’ve even set up a GitHub repository with example projects. This makes Three more than just a 3D scanner, but I’m not exactly sure what I’d do with it myself.

Finally, there’s the cost of Three. It’s being launched on Kickstarter, where early birds could get a 50% discount off the MSRP of US$3,000. As of this writing there are still units available for US$1,650. That’s an unbelievably good price for a powerful professional scanner, which often cost in the US$20,000+ range.

If you’re looking for an inexpensive and flexible 3D scanning solution, you might want to look at Three.

Via Matter and Form and Kickstarter