There’s been an interesting development in how functional solenoids can be directly 3D printed.

Researchers at MIT were interested in 3D printing three dimensional solenoids. A solenoid is an electronic component made from a helix of conductive wire. The wire creates a magnetic field when energized, and this can be used to move metal switches, for example. In other words, solenoids are extremely useful components for all types of applications.

They’ve been 3D printed previously, but only as a single layer. This greatly constrains the possible applications.

The MIT researchers were able to devise a 3D printing system that was able to produce functional solenoids — printed in a single job — that were a third smaller, able to handle twice the energy, and produced magnetic fields with three times the strength. They explain:

”This study explores enhancing the performance of 3D-printed solenoids through device design optimisation and feedstock improvement enabled by significant, yet affordable, 3D printing hardware customisation. The new devices attain a threefold maximum magnetic field compared to previously reported, fully 3D-printed solenoids, while being 33% smaller and capable of withstanding twice the current.”

How did they do it? It seems they used a combination of machine modification and use of unique 3D printing materials.

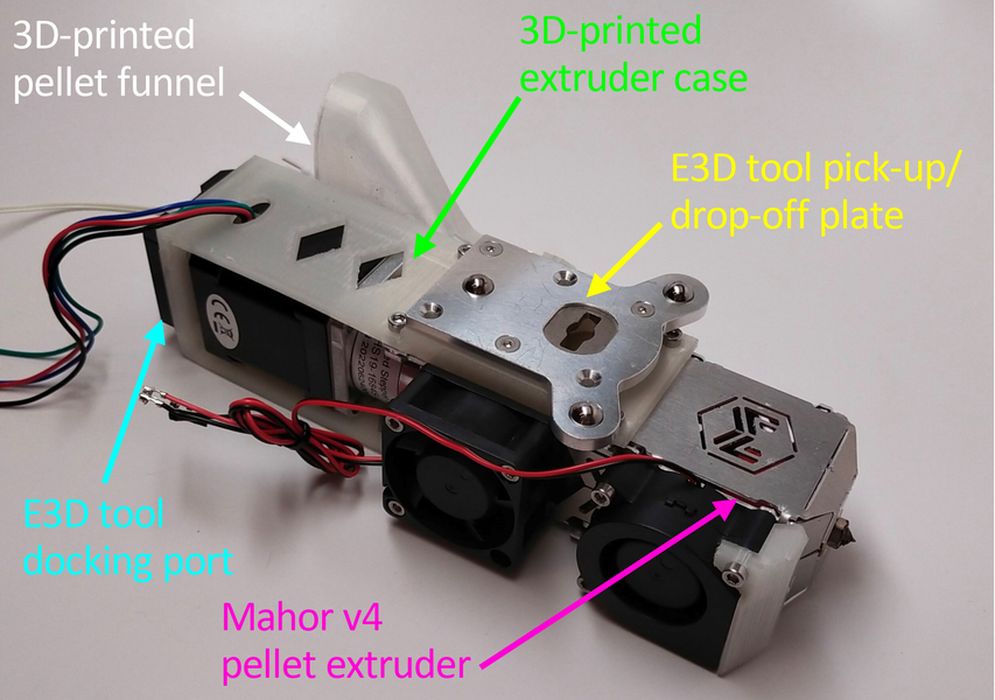

Their 3D print platform was the FFF E3D toolchanger. This device employs several separate toolheads, each fed with a specific filament. They chose this device because it would minimize contamination between materials, unlike shared-nozzle setups.

For materials they used PLA and nylon. However, some of the PLA was strongly doped in order to mae it conductive. The doping was so severe it made it near impossible to form a normal filament from the unique material.

To overcome this limitation they modified one of the extruders to accommodate pellet material, as shown here. This is a unique feature that we haven’t seen on the toolchanger.

This configuration allowed the researchers to 3D print a functional solenoid with multiple layers.

This is an important development, as solenoids are a critical component for countless mechanical and electronic devices. You’re probably using one right now.

The ability to 3D print powerful solenoids, particularly those of a small size, could enable the production of unique types of solenoids that could fit in devices where they could not be with previous methods.

Via MIT and Taylor & Francis Online