I had the opportunity to check out Multec’s amazing six-filament extrusion solution.

Multec is a German company founded in 2011, but began commercial marketing of products only in 2019. They began with desktop equipment, but smartly switched to making professional and industrial 3D printers. Today they market several systems with varying build volumes. One machine, the Multirap M4, is capable of 3D printing metal filament.

But what interested me the most is their revolutionary extrusion system that permits the use of up to six different filaments in the same print job.

Multi-material extrusion is not a new technology; there have been several different methods used, each with notable disadvantages:

- Dual extrusion: an extra extruder is bolted onto the first one, but the “other” extruder drips onto and bumps into the print.

- IDEX: independently moving extruders, solves those issues, but is more expensive to produce and is slower as the print heads must move around more.

- Single Nozzle: material is blended or switched in a nozzle fed by multiple filaments, but when switching materials huge amounts of purged material are wasted. While alignment problems are solved, many more are introduced.

- Toolchanger: A single motion system swaps toolheads in and out during the print job. This solves most issues, but is far more expensive due to additional hardware required and is somewhat slower due to all the toolhead movements.

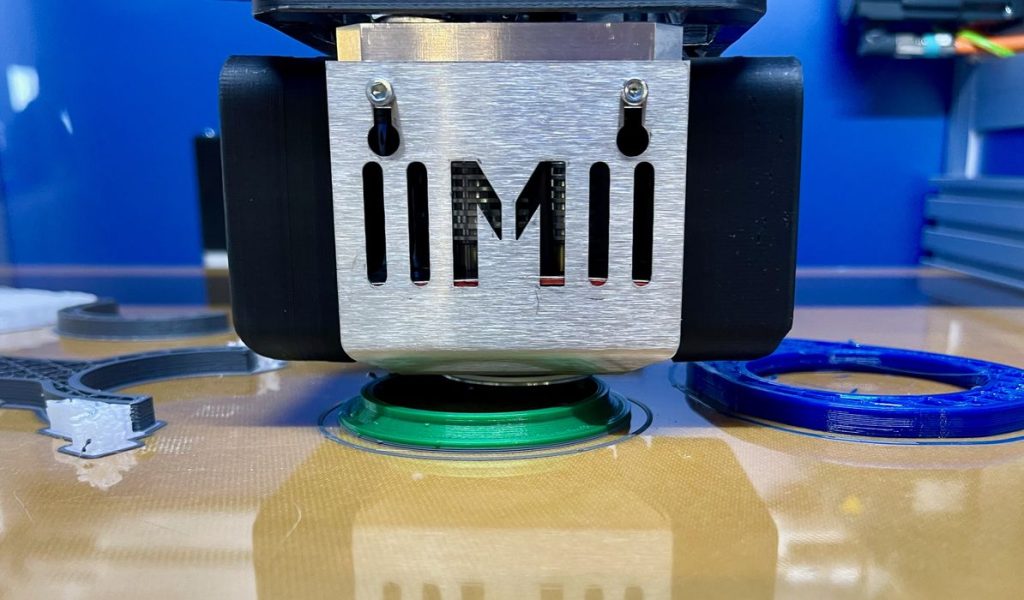

Enter Multec’s “Hexamove” toolhead.

This amazing component can 3D print up to six different filaments in the same print job, and does so with a minimum of hardware and printing delays.

How does it work?

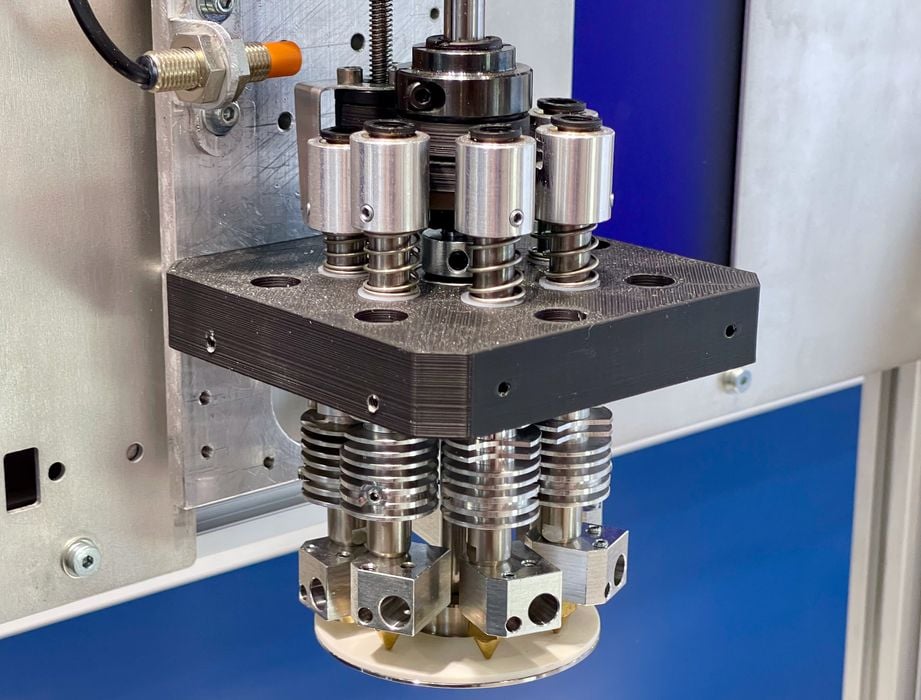

Multec Hexamove Multimaterial Toolhead

There are six hot ends arranged in a circular pattern. These can contain different colors of filament or more usefully, different materials that could be at different printing temperatures.

Underneath the nozzle tips is a rotating plate with an orifice. The concept here is to rotate the plate to expose the active nozzle — and block all other nozzles.

This means that switching a material is as simple as rotating the plate appropriately. Of course, the active nozzle must move down slightly to get past the plate, but that’s all that’s required. Switching materials is therefore almost instant.

Well, it’s not quite instant: we were told it can be done in 0.2s, and that’s pretty quick. Compare that to the time required to purge materials on a single-nozzle system, or change a printhead on a toolchanger system.

There is no need for purging, and no need for nozzle cleaning. It’s incredibly simple.

The only disadvantage I can see with this approach is that the toolhead will be relatively heavy as compared to some other solutions, and therefore the print speed may be less than some high speed alternatives.

In retrospect, this unique design seems obvious, and I’m genuinely surprised it hasn’t appeared previously. Nevertheless, Multec does offer this as an option for their several 3D printer models.

We’re told the systems can be used to 3D print abrasive composite material using hardened nozzles, as well as the ability to handle flexible TPU.

Multec Hexamove Advantages

Multec’s machines are built to run 24/7, as they are industrial machines. One big advantage to the use of the Hexamove is that in theory you could load up multiple spools of the same material and perform “spool swaps” by simply switching nozzles. This would reduce operator effort significantly on long print jobs.

Another possibility is to use different diameter nozzles. It would then be possible to print thick, coarse internal extrusions for strength and speed, while using the finer nozzles for perimeter details. The systems use 2.85mm filament for this reason: more material can be delivered to the nozzle.

Finally, there is the ability to use some of the nozzles as “spares”. Should a nozzle jam or otherwise fail, it could be possible to use an idle nozzle to resume printing.

Multec seems to have an incredible multimaterial solution that is quite versatile. If you’re looking for a multimaterial 3D printing solution, their Hexamove should be of great interest.

Via Multec