FreeD Printing is a software company producing software that can slice your 3D model in ways you can’t imagine.

The issue with today’s slicers is that they insist on preparing your 3D print job to print in sequential layers. There is good reason to do so: by printing in layers the problem of collisions is eliminated: the print head and mechanism is always above the “print line”.

However, FFF 3D printers are completely able to move vertically during the print, and that’s usually not done. There have been some experiments in non-planar 3D printing, such as Gabriel Boutin’s work, or that of FullControl.

Beyond experiments, there is now FreeD Printing, a company that produces a commercial product for doing exactly this.

FreeD Printing is quite new, having been around for only a year and a half, after being developed in Germany as part of University work. Their mission:

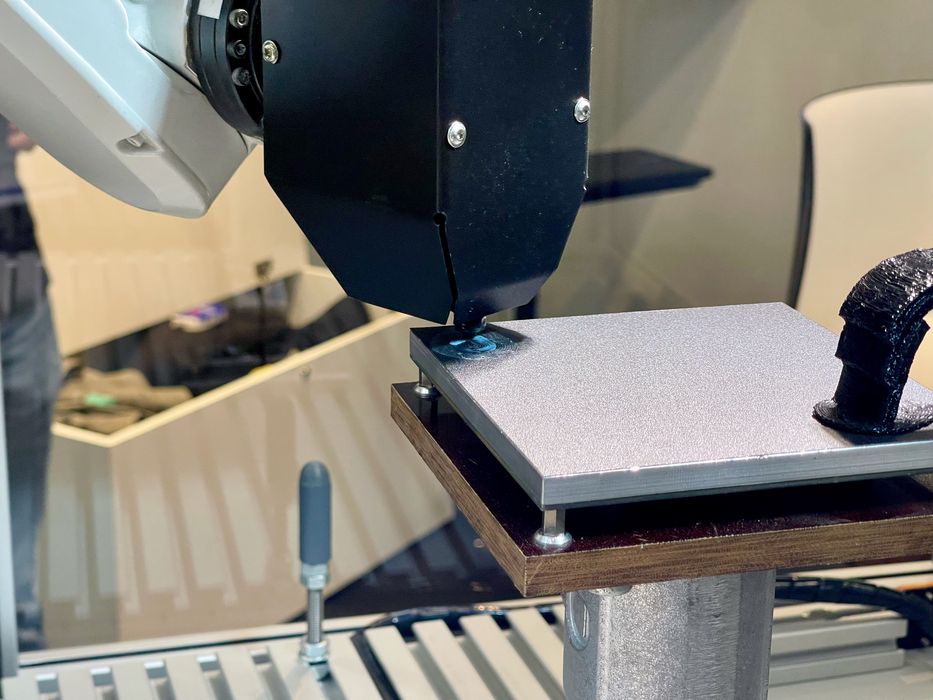

“Additive manufacturing processes offer new possibilities for the production of parts compared to conventional manufacturing processes. However, due to limitations of the common modeling pattern, many of the additive manufacturing systems do not use the full potential that the additive manufacturing processes basically offer. Our modeling method FreeD Printing revolutionizes the modeling pattern of many additive manufacturing processes by using a six-axis robot in the modeling process.”

While the “easy” 2.5D printing normally used in FFF systems is safe and commonly done, there are significant advantages to adding a third dimension to the toolhead’s movement.

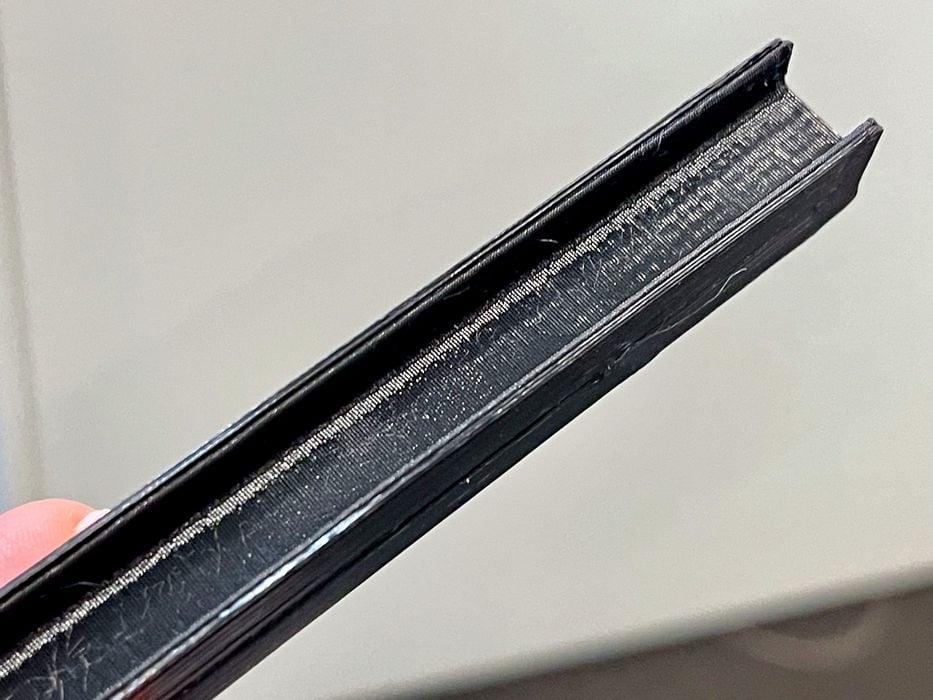

One is that the extrusions can more appropriately match the expected mechanical stresses for the part. Typically 3D printed parts are weak at the layer lines, and if they happen to align with the stress direction, you can have a failure. By extruding in a direction that is counter to those stresses, the part can become far stronger.

A part with extrusions in many directions is generally going to be stronger than a part with uniform layers, simply because the part has extra strength in more directions.

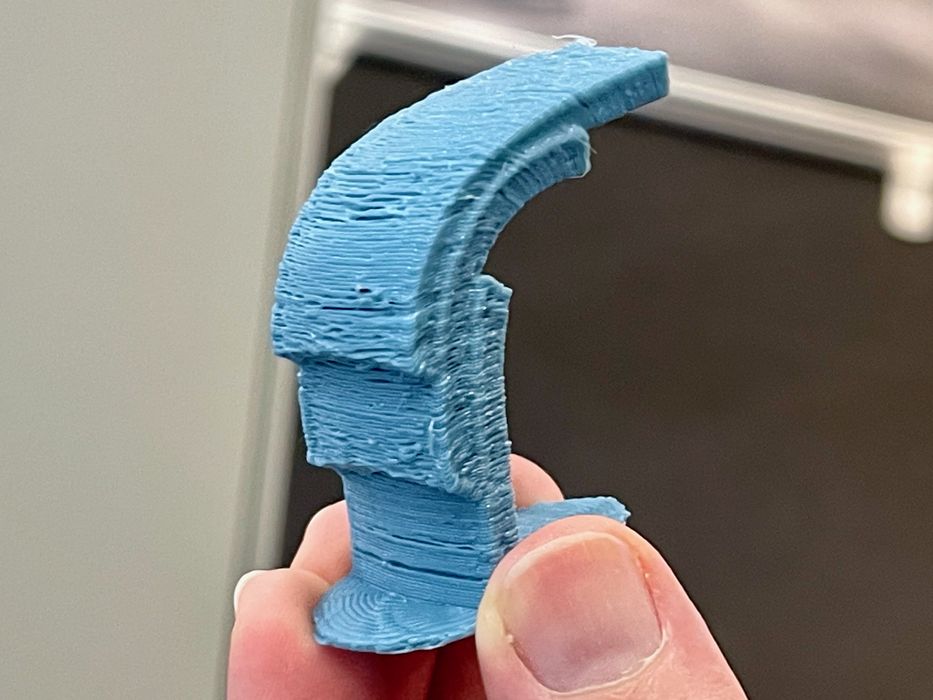

Another major advantage is the ability to mostly eliminate support material. When printing in 2.5D there are frequent situations where a layer is printing on “nothing” below it. Thus, there’s a need to print temporary support structures to hold it up. Unfortunately, these support structures cost effort to remove after printing, leave poor surface quality on the print, and use up extra material.

The nonplanar approach simply twists the print (or toolhead) around to change the orientation from overhang to regular 3D printing. This is done temporarily, as the part (or toolhead) can be moving in all directions freely while printing.

That’s what FreeD Printing does: they produce GCODE to print in curved layers instead of flat layers. These combine to improve part strength as above.

As of today they code produced runs on a six-axis robot equipped with a FFF toolhead. They didn’t say, but I’m hoping they devise a version that works on typical FFF cartesian devices in the future.

The company is still quite new, so their offer is to perform a custom installation for clients, or can provide printing services.

I’m looking forward to seeing how their slicing concept catches on in the market.

Via FreeD Printing