There’s a new scale for 4D printing.

“4D Printing” is something that’s been around for quite a while, yet it hasn’t taken off yet. That’s likely due to its complexity.

The concept is straightforward: 3D print an object that can later rearrange its geometry based on external triggers.

For example, a collapsed tent might be 3D printed, and then upon a signal, it later unfolds into full tent form. The motion is generated through the use of unusual geometries or materials that can activate upon command. That’s 4D printing.

There are countless applications for 4D printing, most of which have not yet been discovered due to its newness.

The complexity comes in when you consider how these items are designed. Typically they are in a single piece, yet exhibit complex folds and twists that are leveraged during activity. That requires some tricky software and big imaginations. The complexity is so high that 4D printing is also referred to as “programmable materials”.

The new research takes the concept of 4D printing to nanoscale.

Researchers used a two-photon 3D printing process to scale down the action, as it is capable of 3D printing extraordinarily small objects. That’s been done previously, but in almost all cases the resulting parts were static, made from rigid materials.

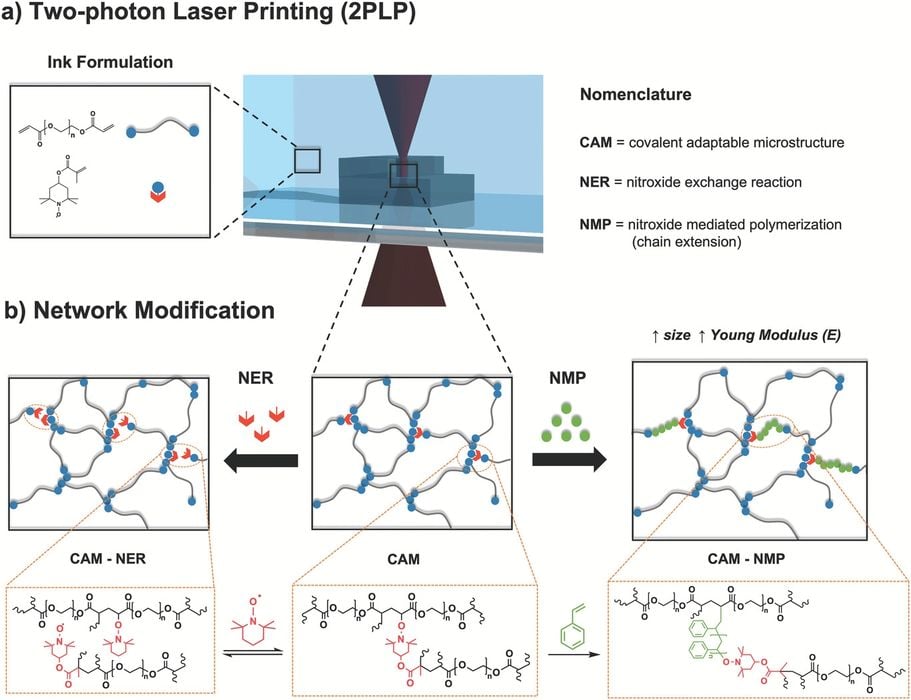

The latest paper describes how researchers used dynamic covalent chemistry, which at larger scales enables repeated and reversible bond breakage and formation at the molecular level.

The use of “living bonds” enabled significant changes in the resulting materials. They explain:

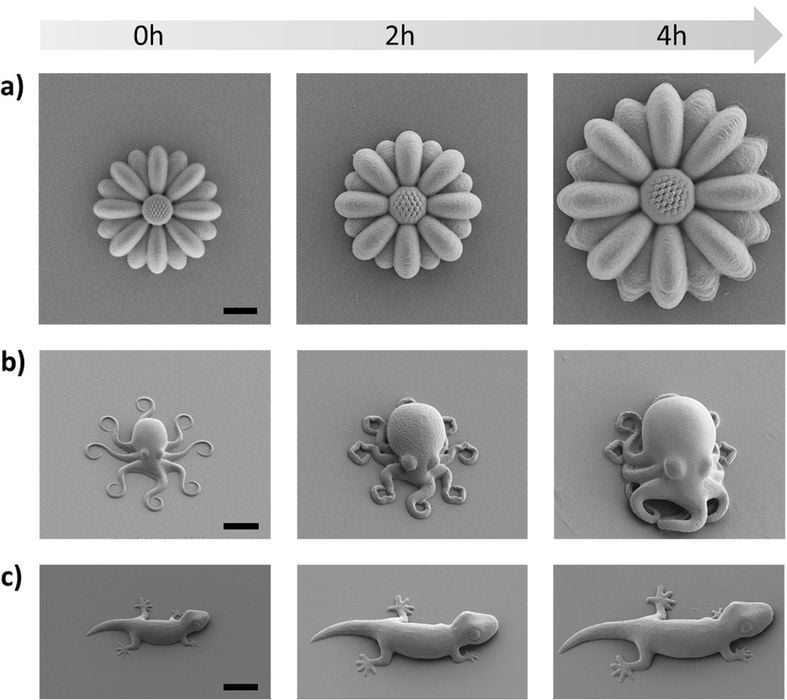

“In particular, living nitroxide mediated polymerization of styrene results not only in a dramatic increase of the volume (≈8 times) of the 3D printed microstructure but also an increase of the Young’s Modulus by two orders of magnitude (from 14 MPa to 2.7 GPa), while maintaining the shape including fine structural details. Thus, the approach introduces a new dimension by enabling to create microstructures with dynamically tunable size and mechanical properties.”

How does this work?

”We report a novel pathway to produce such covalent adaptable microstructures (CAMs) offering precise adjustment of their mechanical properties by postprinting modification after structure fabrication. To achieve this, we combine 2PLP [two photon printing] providing the highest degree of 3D fabrication precision with a simple ink system offering covalent dynamic bonds by incorporation of alkoxyamine functions into printed 3D microstructures.”

What all this means is that they’ve developed a set of new materials that can be used in two-photon 3D nanoprinting applications. These materials exhibit a wide range of properties and thus could be used for nano-scale 4D printing.

This is one of those developments that promises to yield untold numbers of new applications, but it’s so new many will have to be invented by those facing nano-scale problems. One can imagine microscopic valves, gates, switches, in addition to the operational animals and plants in the image at top.

Via 3Druck (Deutsch) and Wiley (Hat tip to Benjamin)