Nanoscribe announced a new variation of their Quantum X 3D printer, the Quantum X bio.

If you’re not familiar with Nanoscribe, they produce a 3D printer capable of printing incredibly tiny objects. While most 3D printers describe dimensions and resolutions in microns, Nanoscribe does so in nanometers: the Quantum X’s minimum feature size is only 100nm, which is 0.0001mm.

Nanoscribe achieves this using their 2GL 3D printing process. It’s an adaption of the more well-known two-photon resin 3D printing approach, which permits very tiny structures to be created within a vat of photopolymer resin.

The Quantum X was announced back in September, and it provides this level of resolution in a 50 x 50 mm build chamber. This allows the machine to 3D print many types of microscopic objects. A typical application would be to produce very tiny optical lens arrays.

The news this week is that they’ve partnered with sibling company CELLINK, a bioprinting company, to produce the new Quantum X bio. This essentially transforms the original Quantum X into a bio printer. Nanoscribe describes the difference:

“Based on Nanoscribe’s engineering excellence, the proprietary additive manufacturing technology is customized and reimagined in collaboration with the expertise of bioprinting experts at CELLINK. The new Quantum X bio brings essential features like temperature control, sterile environment and functionalized biomaterials. Transferring Nanoscribe’s submicrometer resolution to biofabrication is the key to effectively accelerating innovation across life science applications like tissue engineering, drug delivery, mechanobiology, microfluidics and vascularized tissue.”

But what might this mean for bioprinting? Nanoscribe CEO Martin Hermatschweiler said:

“Our industry-proven Two-Photon Polymerization technology, combined with CELLINK’s bioprinting expertise, will be a game changer for many challenging biological and biomedical applications, and we look forward to expanding our market leading 3D Microfabrication position in the life sciences with a dedicated bioprinter. The launch of Quantum X bio confirms the power of collaboration within the BICO Group and we are excited to unlock the full potential at the merger of technical and life science disciplines.”

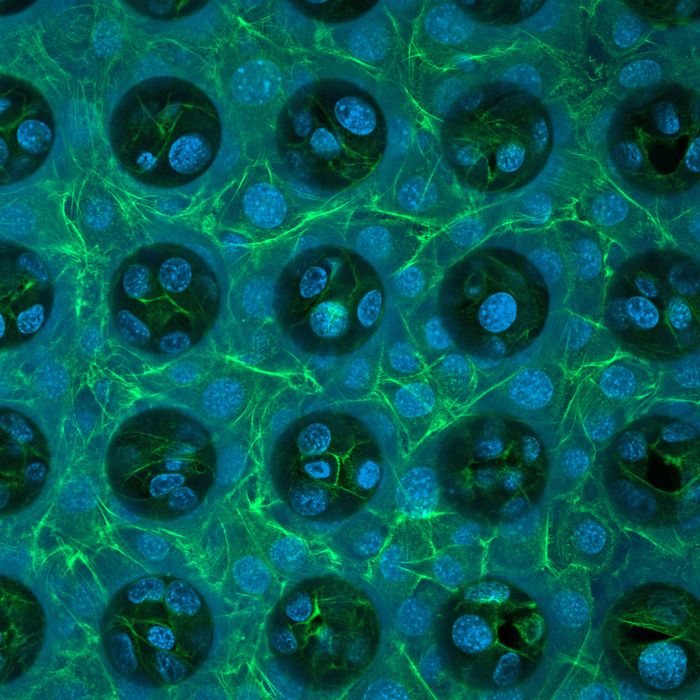

What’s most interesting about this development is that apparently the Quantum X bio will be able to 3D print living cells within the resin. This could allow researchers to develop fascinating micro-mechanisms to perform new types of biological functions. Nanoscribe explains how this could work:

“Live cell printing means printing with living cells in the resin, which is a major challenge because cells are typically under stress while being processed and residing inside the printer. Quantum X bio is equipped with live cell printing features such as sterile, temperature-controlled environment and a cell-friendly wavelength of the laser (780 nm). Moreover, the versatile tool covers biomedical applications like customized microfluidic elements and microneedle arrays or microrobots for drug delivery.”

To do these things, Quantum X bio operators can choose from a very wide range of materials for the device. This includes biomaterials, bioresins, and biocompatible materials.

This machine could open up entirely new bio application forms based on the scale now possible and wide variety of materials. Imagination required!

Via Nanoscribe