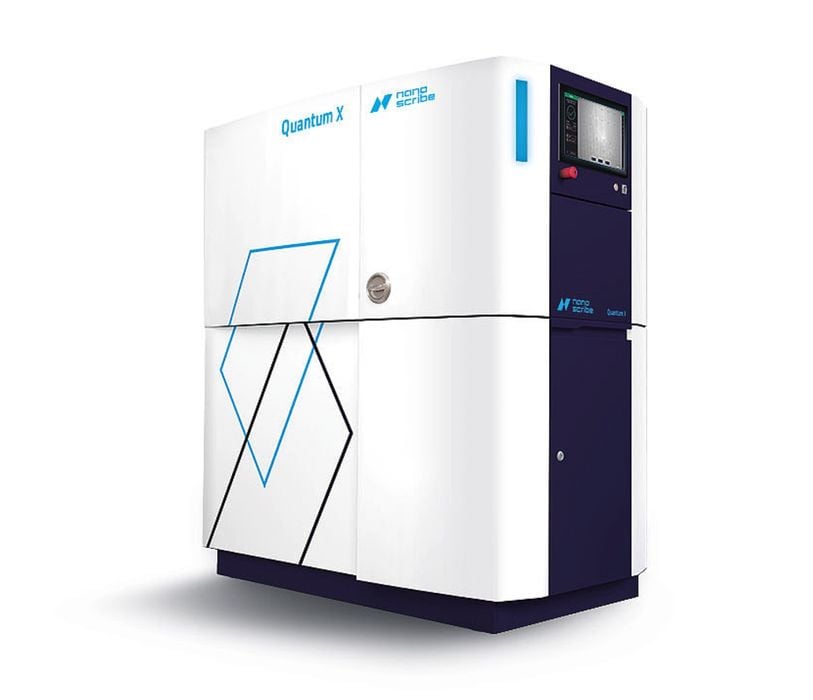

Nanoscribe announced the Quantum X, a new micro fabrication 3D printer.

Microfabrication is the process of making parts at extremely small scales. I’m not talking about objects of only a few millimeters in size; no, we’re talking about objects measured in nm — nanometers.

This is orders of magnitude smaller than micrometers, a typical unit of measurement in the 3D printing community. A micrometer is 0.001mm, while a nanometer is 0.000001mm. That’s incredibly tiny.

Two-Photon Greyscale Lithography

The Quantum X uses a unique two-photon greyscale lithography process, which they call “2GL”. It’s an adaptation of their two-photon polymerization process (2PP), which uses two precision laser beams that overlap to provide sufficient energy to polymerize a voxel within a liquid vat.

The “TPP” process is the 3D printing process that is best able to produce extremely small objects, and has been commercialized by Nanoscribe.

Nanoscribe explains the 2GL process:

“Quantum X controls the voxel size along one scanning plane using synchronized laser power modulation at high speeds. In this manner, complex shapes are produced and variable feature heights are achievable within one scan field. Discrete and accurate steps as well as essentially continuous topographies can be printed on up to six-inch wafer substrates without the need for additional lithography steps or mask fabrication.”

Quantum X Specifications

The Quantum X has specifications very different from common 3D printers. For example:

- Print area: 50 x 50 mm

- Minimum feature size: as low as 100nm

- Scan speed: 6.25m/s

- Typical object dimensions: 50 – 700 micrometers

- Materials: polymer and silica (glass)

Nanoscribe has also opened the Quantum X to using third party resins for custom projects.

Nanoscale 3D Printing

What exactly do you 3D print at this scale?

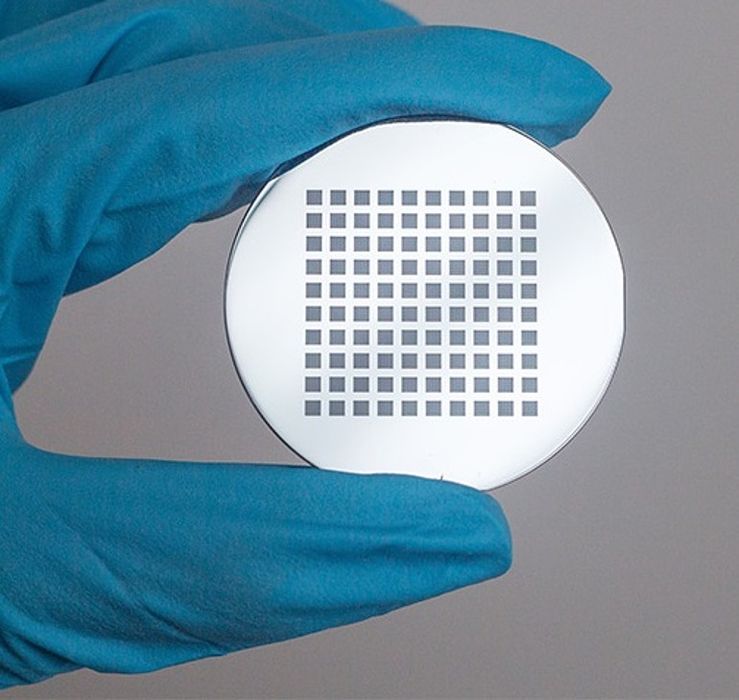

The most popular applications are optical systems. For example, one could 3D print a complex diffractive optical array with multiple elements quite easily with the Quantum X.

In addition, extraordinarily small mechanical parts can be 3D printed using the polymer resin. These could become part of micro-machines that might take on unusual tasks suited for their small size.

However, due to the relatively new introduction of this scale of 3D printing, it’s likely that most of the applications have not yet even been envisioned, and it will take some time for industry to recognize and leverage the two-photon technology at a larger scale.

When they do, the Quantum X could be of great use due to its design for industrial production. The small prints can be made quite quickly with the rapid galvanometric laser movements, and thus achieve significant throughput, depending on the size of the parts required.

Via Nanoscribe