NASA announced they’ve 3D printed a very different type of rocket engine.

Most rocket engines use a combustion method: fuel and oxides are pumped into a chamber, where they burn. The heat created during the burn expands the gases, which are funneled out through the engine bell to create thrust.

Let’s think about combustion for a moment: compare a fire to an explosion. They’re quite different, aren’t they? One is slow and continuous, but the other produces a rapid and energetic reaction.

Would it be possible to make a rocket engine that uses an explosion instead of combustion? That was the question facing NASA engineers.

They came up with a design they call the “Rotating Detonation Rocket Engine”, or “RDRE”.

How does an RDRE work? It’s not what you might initially think: a series of “bangs” one after the other. That’s something different, and it’s called a “Pulse Detonation Engine”. The RDRE is quite different, although both use detonative combustion.

In the RDRE, there are a series of small explosions that occur in sequence along a circular channel. As these explosions occur, a supersonic wave of energy is built up, and that’s channeled out the back of the engine.

This creates a more or less continuous thrust, as opposed to the bump-bump-bump of the pulse approach.

Why build this kind of rocket engine? The efficiency of a rocket engine is largely determined by the speed of the exhaust, and RDRE offers supersonic speeds. The approach can be up to 25% more efficient. That means you can lift 25% more weight, for example.

As you might imagine, the design of the RDRE is extraordinarily complex: there are countless tiny channels that carry fuel and oxidizer to the circular channels, and everything must be in proper alignment for the detonation sequence to work properly.

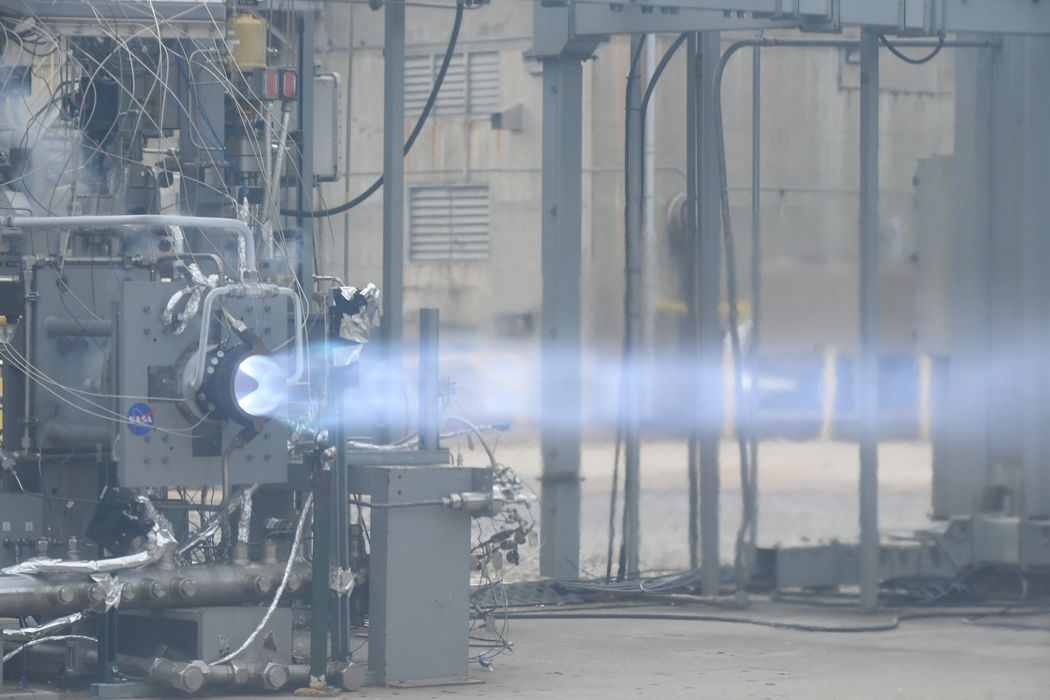

This complex design can only be produced using 3D printing, and that’s precisely what NASA did on this project. You can see the results here:

NASA’s role is to provide new aerospace technology as well as the more public space exploration activities. This project is the former, and it will hopefully lead to the widespread use of rotating detonation engines for future space vehicles.

And a lot more metal 3D printing, too.

Via NASA