Several new AM materials were announced in the past week.

We often receive notes from manufacturers that have developed new and unique materials, but most times the news value is relatively low and these do not warrant a story on their own. However, we thought we might bundle together several material announcements into one post, this one, for your review.

iSQUARED Flexible and Colors

iSQUARED produces “plug compatible” materials for Stratasys equipment, both for FDM and PolyJet processes. Their pricing is a bit lower than Stratasys’, but you’d best check your warranty before using their products.

If you’re able to use iSQUARED materials, you might be interested to learn they’ve just launched a new PolyJet material, IORA Model Flex 30A Black. This resin is billed as an alternative to Stratasys’ TangoBlack Plus and Agilus30. It’s an elastic material that can be used for production end use.

They have also launched a new line of color cartridges for the Stratasys full color series, including the Connex3, J735, J750 and the brand new J750 Digital Anatomy 3D printer. These can be mixed in the machine to produce any of 500,000 different colors.

Kimya PETG

Kimya has launched a new PETG made from recycled materials. The new filament, Kimya PETG-R is apparently made from 97% recycled materials. Hold on, what’s the remaining three percent made from?

The missing three percent is pigments, so don’t fear there’s non-recycled materials in the mix!

In fact, Kimya offers this new material in white, black and “natural”. The natural option is actually 100% recycled, because it contains no pigments at all.

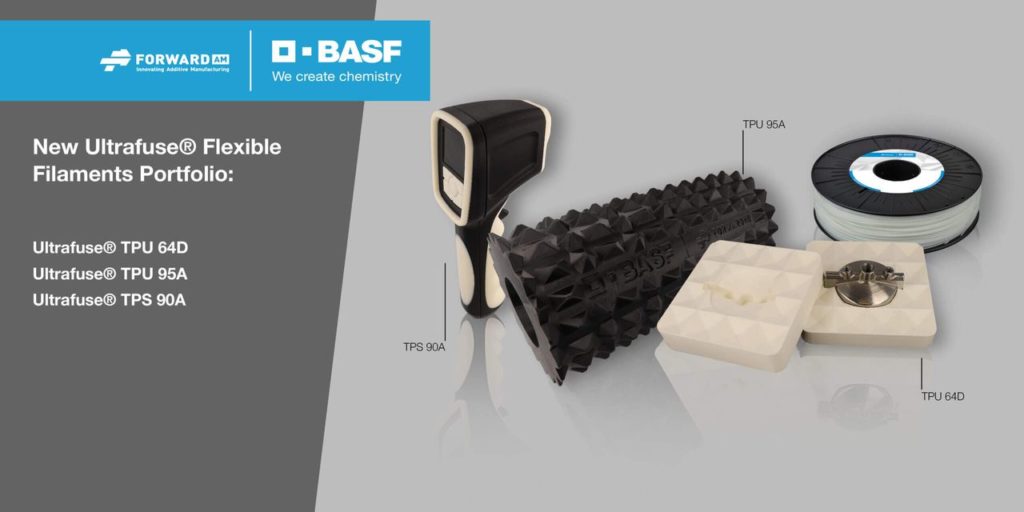

BASF Ultrafuse Flexibles

BASF’s ForwardAM unit announced a new line of Ultrafuse filaments that are flexible. The three new products are:

- Ultrafuse TPU 95A

- Ultrafuse TPU 64D

- Ultrafuse TPS 90A

These are TPUs and a TPS material, each with different Shore hardness values as indicated.

Each product also has different properties aside from hardness, which will be of interest to those using it for specific applications.

Desktop Metal IN625

Desktop Metal announced the certification of IN625 for their metal Production System.

This is a nickel alloy, Inconel 625, that’s often used in high temperature, environmentally difficult applications. It’s able to withstand quite a range of temperatures, and is highly resistant to chemicals. Desktop Metal explains:

“A nickel-chromium superalloy, IN625 is characterized by its high strength, resistance to corrosion and oxidation, excellent weldability, and ability to withstand extreme, elevated temperatures for parts under load. IN625 is a critical material used extensively in high temperature aerospace applications, while its corrosion resistance under a range of temperatures and pressures also makes it an excellent choice across marine, power generation, and chemical processing applications.”

Via iSQUARED, Kimya, Forward AM and Desktop Metal