Some very interesting developments at One Click Metal.

No, they haven’t invented full-color metal 3D printing, as the image above shows metal parts 3D printed by One Click Metal, but post processed to have brilliant colors.

You may recall that the company produces an economically efficient medium-volume metal 3D printing system, which has a modular design. Their use of cartridges basically solves the powder exposure problem, as it’s easy to move material and prints through the workflow in a safe manner.

They focus on a simplified workflow, which is where their name comes from: it’s not quite “one click”, but the steps involved are straightforward and easy for newcomers to metal 3D printing to adopt.

Their system is now quite refined, and we were told that one of the few recent changes was the addition of an extended build module for their BOLDSERIES of 3D printers. The normal build volume is 150 x 150 x 150 mm, but with the extended module the Z-height is stretched to 230-250 mm. That enables customers to produce longer parts.

Another improvement is the addition of a “heat” module, that can warm powder for more effective printing.

They’ve also added to their portfolio of materials usable in the system, with the release of titanium. Their materials selection now includes:

- Aluminum AlSi10Mg

- Tool Steel M300

- Nickel Alloy Ni625

- Nickel Alloy Ni718

- Stainless Steel 316L

- Stainless Steel 174PH

- Titanium Ti6Al4V

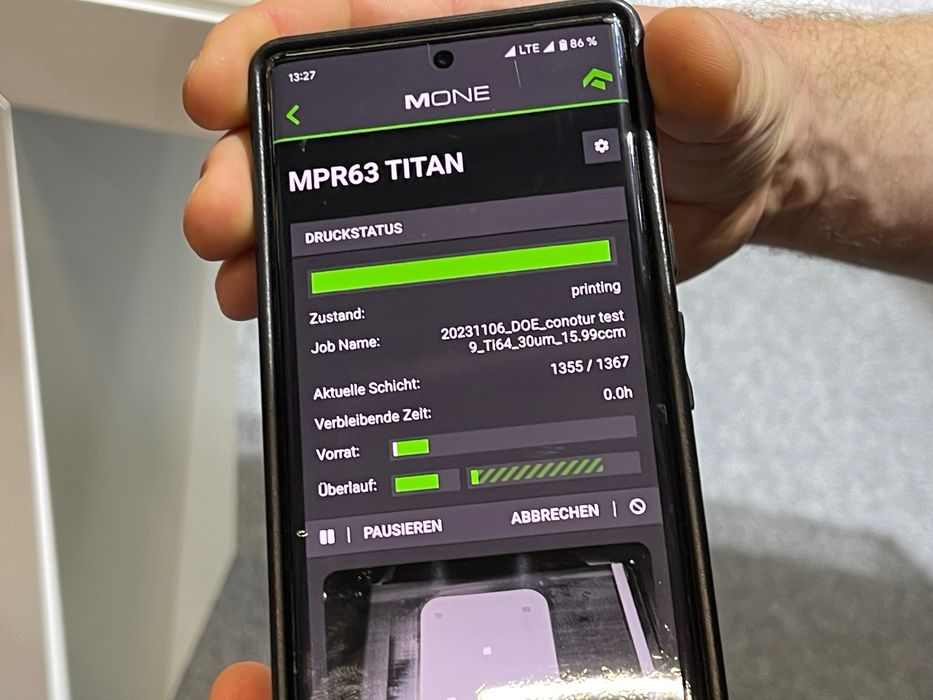

They’ve also made some improvements to their software system, which can be used through the MONE app shown here. The latest improvement includes notifications to operators when powder is running low. The idea is to get the operator to prepare the next load BEFORE it actually runs out. This simple adjustment saves a bit of operation time and makes the system somewhat more economical to operate.

But those are minor tweaks. The company is now strongly focused on sales, as their technology is considered robust. We’re told they have had considerable interest from certain industries, including dental, a very large market. They’ve also had interest from industry for parts and tooling production.

One Click Metal seems to be in a good position for future growth.

Via One Click Metal