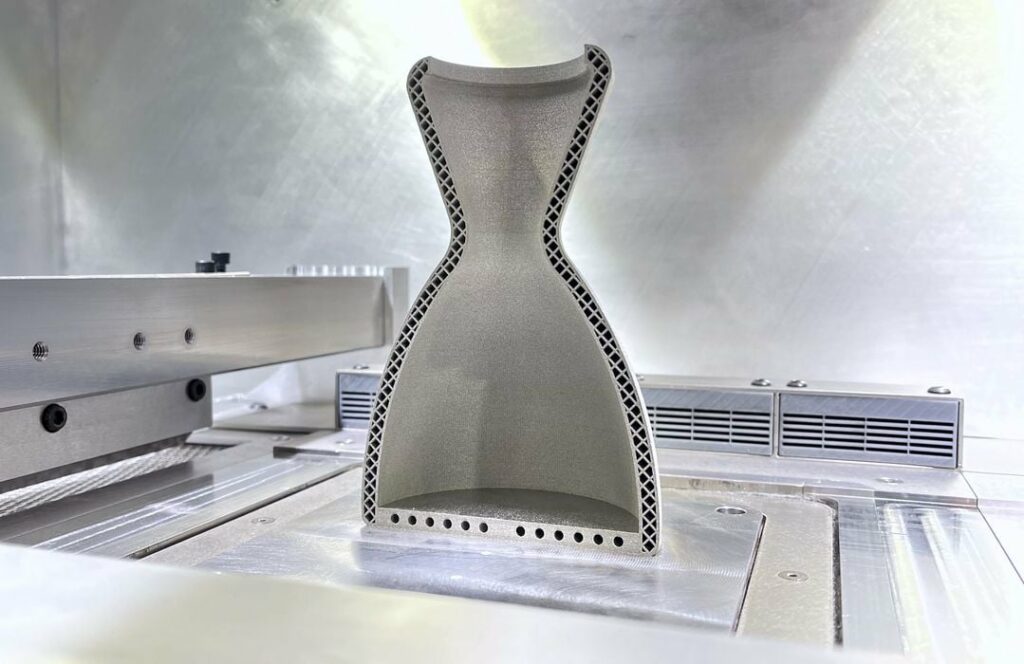

I took a look at Open Additive’s new Panda 2.0 metal 3D printer.

If you haven’t heard of Open Additive, they are a small producer of metal 3D printing equipment, based in Ohio. Formed in 2018, the company produces the PANDA metal 3D printer, which today is equipped with features attractive to researchers and manufacturers.

As you might expect from the company name, the PANDA 2.0 system has “no materials restrictions”, and you’re thus able to use any metal powders you’d like in the system. However, Open Additive will provide at no charge, the print parameters for these frequently used materials:

- Stainless steel 316L and 17-4 PH

- Aluminum alloy AlSi10Mg

- Nickel-chromium alloy In718

- Titanium alloy Ti-6Al-4V

Of course, operators are free to experiment with parameters for these and other materials on the PANDA.

The PANDA is actually several variations, as there are multiple configurable features. The most important is the build volume, which can be either 152 x 152 x 241 mm, or a larger 280 x 280 x 318 mm. Laser power can be either 500 or 1000W, and there are options for scanning mechanisms. There are also options for pre-heat level, and finally Open Additive is “open” to building custom variations on request.

There are several convenience features on the PANDA 2.0. One that I particularly liked was the “Powder Catch”. They explain:

“Another useful feature of the PANDA design is the addition of a powder catch that funnels into a container below the process chamber deck, making it easy and safer to extract unused powder (rather than hand scooping it out of a collection bin). Powder is swept into the catch, going into a metal canister with screw top and handle that can be removed and replaced using the convenient second door, as shown below. The catch area is enclosed as part of the overall sealed chamber.”

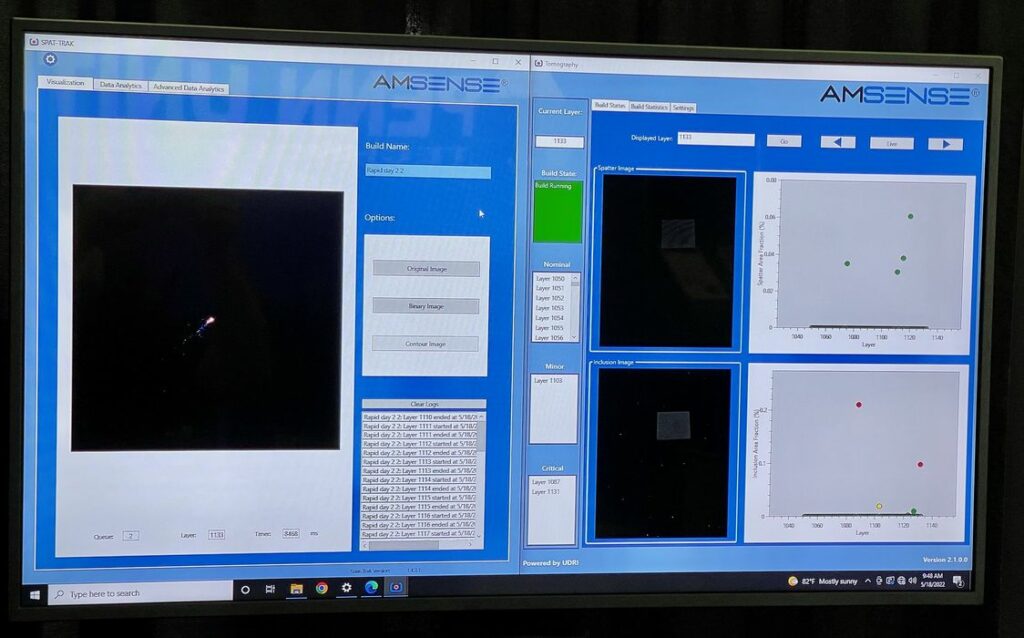

Open Additive also produces AMSENSE, an “advanced quality control system for metal laser powder bed fusion” processes. The tool scoops up data from five types of sensors and provides full access to collected data along with analysis. The sensor types include:

- Thermal tomography

- High speed spatter imaging

- Recoat imaging

- Long-wave infrared imaging

- Coaxial melt pool sensing

- Simple sensors such as photodiodes, thermocouples and others

AMSENSE can be used with the PANDA or other LPBF equipment.

While it took a few years to develop the PANDA, we’re told that the company intends on integrating subtractive technology to create a hybrid system.

For now, Open Additive sells equipment only directly from the company, but might consider branching out into the reseller market in the future.

Via Open Additive