Charles R. Goulding and Ryan Donley consider the Pentagon’s leadership in robotics, and where 3D printing plays a role.

Ordinarily, we wouldn’t be looking for the Pentagon to provide technology leadership in a major industry category. However, that is exactly what’s happening with robots. A Wall Street Journal article indicating that whether by land, in the air, or under the sea, the Pentagon is outpacing the private sector in the use of unmanned technologies. Many of the companies working with the Pentagon on these robot technologies are major users of 3D printing, including Boeing for unmanned aircraft, the Sikorsky division of Lockheed for unmanned helicopters and Huntington Ingalls Industries’ unmanned Orca undersea vessel. Our view is that both the robot and the 3D printing industries should keep a watchful eye on these new technology developments.

The new January 2021 $740 billion Defense Authorization Bill contains many provisions aimed at expanding autonomous operation across all the military services. We sometimes forget that mainstream manned equipment design is often constrained by the need to accommodate a human being. Once you eliminate the human being and the accompanying extensive human support needs, the entire product can be totally reengineered.

Boeing

Boeing has long been involved with additive manufacturing practices, including in unmanned vessels and similar technologies. Today, Boeing is delivering nearly 1,000 additive manufactured parts across flight programs with plans to sharply increase the number of parts.

Global demand is continually rising for new aircraft in particular, unmanned aerial vehicles (UAVs). The Air Force is even keen on Boeing providing the capability to refuel aircraft mid-flight without any crew members guiding the process.

Lockheed Martin

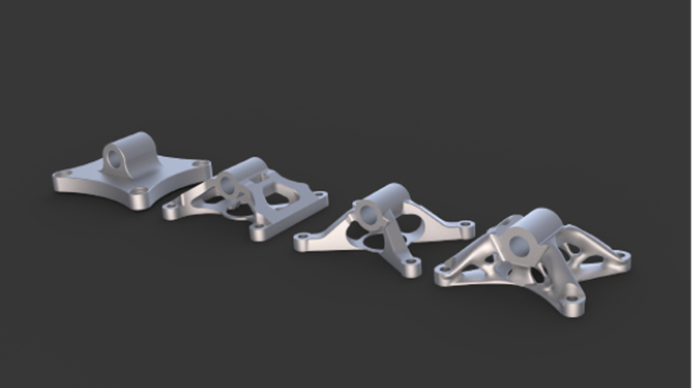

Lockheed Martin has been leveraging additive manufacturing throughout its practices for numerous years. The Sikorsky helicopter division, in particular, has been developing technology for advancements towards autonomous helicopters. Sikorsky’s MATRIX technology program is combining software and hardware components to enable autonomous flying experiences in military applications. Currently, Sikorsky is developing 3D printed niche components for the popular Blackhawk helicopter, which is also undergoing autonomous technology implementation.

Huntington Ingalls Industries

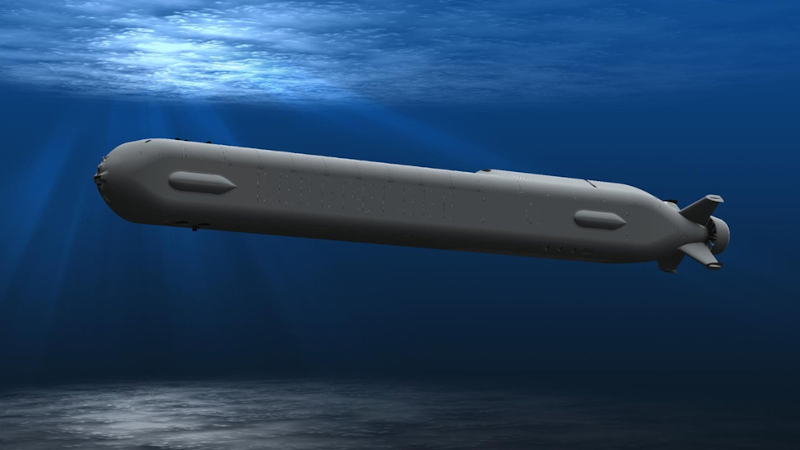

Huntington Ingalls is known for its expertise in building aircraft carriers, submarines, and other ships for the United States Navy as the company has grown to be the largest military shipbuilding company in the U.S. Huntington Ingalls has been behind the manufacturing of numerous 3D printed parts that are currently at sea which includes piping assemblies, drain strainer orifices, and other metal additive manufactured parts. Recent Naval interest is now geared towards unmanned undersea vehicles. This includes the development of the ORCA XLUUV unmanned submarine which is being constructed by Boeing. Huntington Ingalls is assisting Boeing in the effort as they are manufacturing and assembling parts towards the ORCA submarine.

3D printing and similar activities used for developing military equipment may be eligible for Research and Development (R&D) Tax Credits.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

Military interest in unmanned vehicles for land, air, and sea is increasing as solutions for safer and efficient mission completion are sought after. The success of various unmanned aerial vehicles over the years has led to the wide expansion of unmanned vehicle development across multiple military branches. We expect the Pentagon technology leapfrogging to begin to influence commercial innovation and include 3D printing.