This week’s question is about photogrammetry services.

Reader Kevin asks:

”I am looking for a company to make 3D printed parts for me from photos I have taken of the objects. Can you recommend a company that could do this using photogrammetry software.”

This is a common issue: one has a part and requires more copies of it made. However, I think we might be jumping the gun here by selecting photogrammetry as the answer.

Without knowing more about the project, like the level of detail required, object geometry complexity and other factors, the correct answer is usually the shortest path to the goal: a replicated part. That may or may not involve photogrammetry.

Note that we may not even have to use 3D printing technology for this project, if the part is not particularly complex. However, in almost all cases we would need a 3D model to do much of anything. The issue is in how you get a 3D model from a part.

There is really only one way to get a 3D model, and that is to design it using a 3D CAD software tool.

Hold on, couldn’t we use 3D scanning to capture the part instead? Yes, and no.

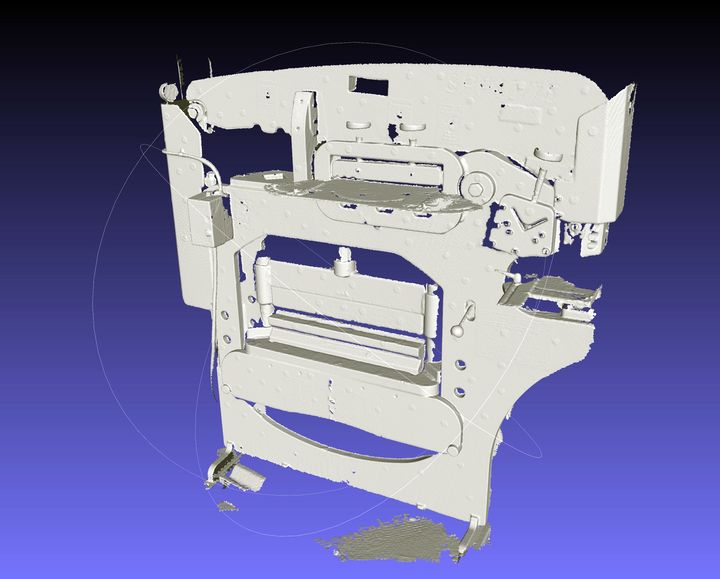

3D scanning systems, even the most expensive, cannot produce a perfect 3D model. All scanners have certain levels of accuracy, and that resolution inevitably results in surfaces that are “bumpy”. The scanners literally can’t “see” any closer. If one were to 3D print (or CNC machine) those surfaces they would be noticeably imperfect. There are other issues, particularly in parts that have movable joints.

But what about photogrammetry? Photogrammetry is simply another method of 3D scanning, one that doesn’t require the use of a dedicated 3D scanning device and instead uses optical imaging. The idea is to capture a lot (and by “a lot”, I mean HUNDREDS) of high-quality images from all conceivable angles of the target part. These images are then processed using specialized software to develop a 3D model of the part.

However, the photogrammetry scan’s accuracy is similar to that obtained from dedicated 3D scanning hardware: it’s not perfect. The only case where a 3D scan might be directly 3D printed is for organic objects, like sculptures or scans of people, where dimensions and surface quality matters a lot less.

What can one do with a 3D scan if they can’t really be 3D printed?

There is a process called “reverse engineering”, in which the 3D scan is used as a guide to create an entirely new, replacement 3D CAD model using Autodesk Fusion 360, SOLIDWORKS, Blender or similar system. It’s much like tracing a 2D image; instead a 3D CAD tool “traces” over the rough 3D scan to create a perfect CAD model. Then you throw away the 3D scan because you’ve made yourself a true 3D model.

There’s an important question to ask at this point, however: do we really need a 3D scan if we are re-making a 3D CAD model? What if the geometry of the original part was straightforward enough to simply build it from scratch using some measurements? Then we would just do that and skip the 3D scan completely.

Once the 3D model is created, it’s a simple matter to 3D print it, or even CNC mill it, if it has a simple geometry. 3D printing should only be used if less expensive than CNC milling (not often) or the part has a geometry that can’t be CNC milled.

It sounds like reader Kevin has taken some images of the part and wants to send them to someone for development into a 3D model. That’s likely not going to work for several reasons.

Photogrammetry really doesn’t work to any degree of accuracy and quality unless there are a massive number of high-resolution images provided. Typically you’d want in excess of 500 images, all taken very carefully from every possible angle. You want to expose each surface to the camera, and that requires some planning. You’ll also need 360 degree even lighting without shadows, and use a lens and focal system that provides for crisp subject AND background in the images. If the part has any reflective surfaces, they have to be covered over with a non-reflective coating. Believe me, collecting images for proper photogrammetry is not an easy task.

It may be easier to simply send the part to a service and have them 3D scan it directly using whichever system they offer, rather than attempting photogrammetry imaging on your own. The service should also offer reverse engineering CAD services to convert that capture to a proper 3D model.

Recently Shining 3D announced they offer a reverse engineering service, aimed at users of their tabletop 3D scanner. That might be an option, if reader Kevin had a 3D scanner or wanted to purchase one. However, that might be financially infeasible if it’s only for a small number of parts.

There are any number of engineering firms that can perform photogrammetry, and one close by should be selected as they will most likely require the part to be present for them to take images. Just make sure your service isn’t one dedicated to aerial drone photogrammetry, which is different from 3D parts.

After all this, the 3D model of the part should be produced one way or another, and we can consider having it 3D printed. This can easily be done by simply submitting the 3D model to any of several popular 3D print services, such as Shapeways, Sculpteo, i.materialise and many others. One consideration is the material required. If, for example, the part is to be made in a specific metal, then you’d have to select a 3D print service that offered that material. Not all 3D print services offer metal materials.

Yes, there are multiple ways to replicate a part, but photogrammetry is only one part of one way to do so.