Alessio Lorusso, Founder and CEO of Italy-based ROBOZE, shares a look at 2020 and a look ahead to 3D printing strategies for 2021.

ROBOZE In 2020

The past year has been dynamic for everyone the world over. The early spring in Italy, though, meant an early epicenter for the novel coronavirus pandemic. We caught up at that time with Lorusso about what it was like to run a 3D printing company in Italy during the hardest-hitting time of the pandemic’s early days.

“We were the first to face the first wave in March,” he said in our catch-up this week, reflecting on that time. “We all lost someone, or nearly lost someone, in Italy. It was tremendous. Now, we take care, we are managing — I won’t say it’s under control, because it’s a pandemic and pandemics are not by definition under control. During this year, we understood how companies need to refocus their attention, to reshore their production. But they really need to do this in a smarter way.”

That level of understanding global conditions on both people and business permeated through ROBOZE’s overall reactions and evolving strategies in 2020. Much of what they worked toward built upon already-laid foundations, but the pandemic — like with effectively every business decision this year — accelerated those plans.

ROBOZE Distributed Manufacturing

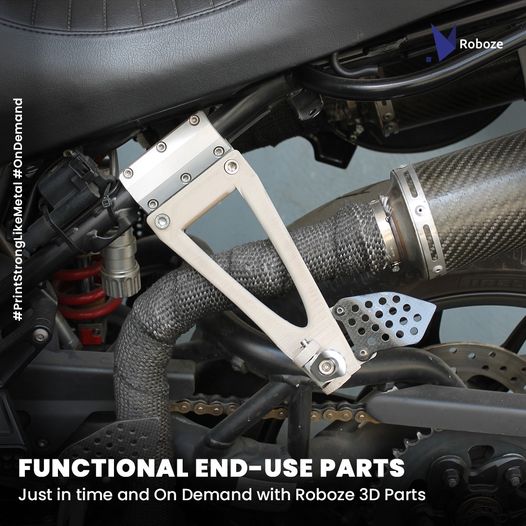

ROBOZE launched a distributed manufacturing service that has proven key to their ongoing strategies — and the way they see businesses pivoting for the long term.

“Thanks to our manufacturing as a service network, we understood how this sentiment is really important for companies. We had hundreds of companies in the last six months get the parts they need just in time with our parts partners,” Lorusso continued.

ROBOZE 3D Parts provided a vehicle for the company’s distributed manufacturing vision. They now have 10 partners and the CEO notes they “will add an additional 15-20 partners next year to cover four continents.” With the EMEA and North American regions currently covered, extending that continental reach will broaden the ROBOZE “print strong like metal” offerings. And that reach is already quite broad; Lorusso noted that through the network, more than 50,000 customer parts have been 3D printed over the last six months.

“We are really focusing our attention on getting the customer the parts they need, or the machine if they want to internalize their production,” he said.

With a focus on local distributed manufacturing through their partner network, ROBOZE’s “goal is to reshore the supply chain, to bring production back to the United States, back to Europe,” he added. For ROBOZE, this move provides a sustainable business model and works to get their high-temperature ARGO 3D printing solutions into the world.

The bigger picture here is “not to sell a machine, but to sell an industrial solution,” Lorusso explained. Sometimes that means selling 3D printers, other times working toward on-demand manufacturing services — and sometimes a combination of approaches.

Industrial solutions with scaled production via additive manufacturing are becoming a more realizable future.

The ROBOZE solution is focused on that future, with some important aspects when it comes to production: a qualified printing process; full print control; digital twins; consistent quality with beltless 3D printing technology. Lorusso understands the need to provide quality assurance for production scalability, including focus on standards and consistency.

“In my opinion, 3D printing can become a real production technology,” he said. “It is about producing parts, even in customized production where you need to prove you can produce anywhere the same result, see repeatable results. Otherwise, it’s just a one-off technology; otherwise, it’s just a prototyping technology. If we want to talk real, customized production, even talking a few hundreds or thousands of parts, those few hundred or few thousand parts must be the same. They must have the same mechanical properties. Everything must be the same. After three months, you need to be able to print the digital twin made months ago and use the same GCODE.

This is what we’ve created. We are now putting it on the table and scaling it. Quality scalability, standardization, the same tolerances: everything must be the same in the world but doing it locally, close to the point of use. We are providing all options to our customers; if customers need just hundreds of parts per year, machine ROI would not make sense. You would then want to get your parts through our manufacturing as a service.”

Overall, Lorusso said: “We want to solve problems, cut costs, cut time. We need to do a more responsible approach with our customers. We are committed to do this.”

ROBOZE In 2021

On top of the distributed manufacturing focus, ROBOZE has more to distribute for the coming new year: the company.

Earlier this year, ROBOZE opened its third international HQ, with a new German subsidiary expanding its EMEA business reach. ROBOZE GmbH follows the 2017 establishment of ROBOZE Inc. in the US; both follow the original 2013 founding of ROBOZE spa in Bari, Italy. With all these locations, ROBOZE has made clear its global intentions — and expanding its markets in the EMEA and North American markets is a major goal for 2021.

Last year, ROBOZE noted intentions to focus on the US market. Next year, those intentions will come to further fruition in a big way: the CEO and some of the executive team are moving to Houston, Texas in the next few weeks.

“The next year will be huge for us,” Lorusso noted. “Right now, we are almost 85 [employees]. The hiring plan for the next year is around 60 positions: we want to become 150 people in the globe, with 35-40 people in the US, split in the US headquarters and other remote locations for sales managers and engineers. We are growing very fast.”

Part of that growth is also set to be financial, as Lorusso continued:

“We will welcome new investors very soon. We are a company really committed to helping companies scaling production. At the same time, we are working on new technologies and new materials. We are really putting on the table a lot in terms of investment: people investment, money investment, everything will be crucial to bringing additive manufacturing to the next level.”

ROBOZE will be creating “huge” application engineering teams, business management teams, and sales teams, all working closely with customers.

“We are not $3,000 Chinese manufacturers, with all due respect to $3,000 Chinese 3D printer manufacturers. Our customers expect from us the best in terms of mechanical performance, tolerances, and after-sales support. After you pay almost $300K, you expect the best. We are concentrated more and more in getting our customers the best in terms of performance and more from our technology. Creating a global team to work closely with our customers. Investing time, financial resources,” Lorusso said.

And in that expansive vision, “the US plays a central role.” ROBOZE is projecting that in 2021, fully 65% of company revenues will come from the US. Manufacturing knowledge and technology development will continue apace in Italy.

There’s more to come from ROBOZE, of course, as the company continues to eye huge opportunities the world over. A new membership program will be deployed in the coming weeks, building further close relationships with customers. This will take the increasingly-popular ecosystem approach to scaled industrial additive manufacturing, further democratizing ARGO technology especially for small and medium businesses.

Via ROBOZE