Relativity Space achieved their milestone this week, sort of.

Readers may recall last week’s story about the California-based rocket company, where they were about to hit a major milestone in the history of 3D printing.

The company, unlike others in the rocket business, is literally 3D printing the entire rocket. Whereas other companies 3D print the engine and use conventional manufacturing for the rest of the vehicle, Relativity Space is just printing all of it. Well, not quite all — the company reports their first rocket, the Terran 1, is actually 85% 3D printed.

To do so they developed a custom “rocket” 3D printer, the “Stargate”. It’s basically a welding rig on the end of a commercial robotic arm. This arrangement is able to reach far enough to 3D print the metal rocket.

Their printing process is interesting: the build plate rotates, allowing the robotic arm to deposit perfectly circular layers to build up the rocket body. Note that this portion of the print is literally the fuel tanks, so they must be incredibly robust to withstand not only the mechanical stresses of launch but, also the extreme thermal stresses of high engine temperatures and low temperature from the liquid fuel and oxidizer.

The big question has been: is this a feasible thing to do? Could a 3D printed rocket actually work? Would the rocket blow apart at the (layer line) seams?

No one knew whether this concept would work.

Because of that, all eyes were on Relativity Space’s first attempts to launch the Terran 1 rocket last week. Unfortunately, the rocket did not get off the ground due to non-3D print related reasons.

However, Wednesday night they had a third attempt to launch the vehicle and they succeeded — and failed.

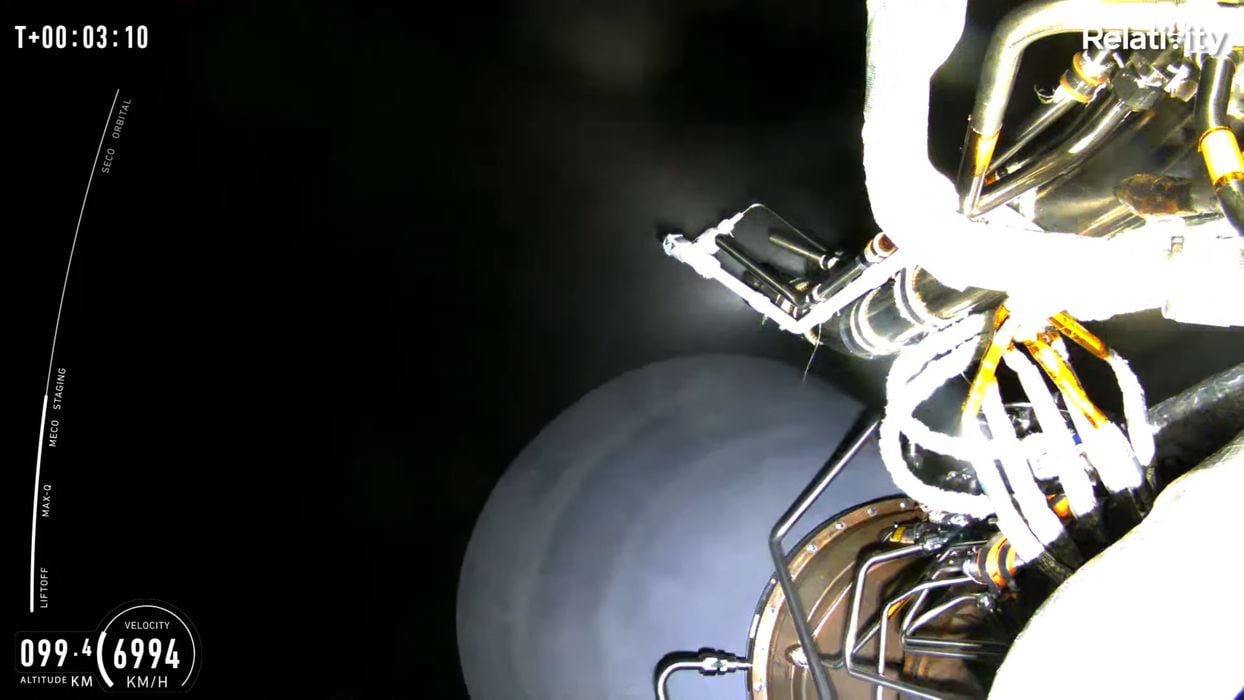

While the first stage carried the vehicle to great speed and height, there was some kind of issue with the second stage, which did not seem to engage properly. Without that thrust, the vehicle eventually plunged into the ocean.

That was the failure part of the event. However, there was also a massive success as well.

The first stage performed well, and pushed the rocket cleanly through what’s known as “Max Q”. This is the point along the rocket’s trajectory where it experiences the maximum amount of pressure against the air. Above that point the air becomes thinner and the “Q” drops.

Max Q is the point where a poorly built rocket will most likely blow up from the extreme air pressure.

That did not happen on Wednesday night: Terran 1 sailed safely through Max Q, much to the delight of Relativity Space staffers monitoring the vehicle’s progress.

After the first stage was dropped off, the video shows that the second stage did not lit properly, causing the mission failure.

While the first Terran 1 mission ultimately failed, Relativity Space proved something very important: it is definitely possible to 3D print entire rockets and by extension, other aerospace vehicles that undergo less stress. This is a big milestone for additive manufacturing, as it opens the door for even more radical rocket designs that could be more efficient and effective.

Well done, Relativity Space!

Via Relativity Space