Relativity Space revealed Terran R, their fully 3D printed reusable rocket.

The company has been building the technology to inexpensively launch medium-sized payloads around the concept of full reusability. Traditionally, rockets were entirely expendable: they would be abandoned after a single flight, making flights extraordinarily expensive. That’s why only governments typically operate above the Earth.

However, reusability seems to be the key to opening up space, as has been exploited for the last few years by SpaceX, which developed a partially reusable medium-sized rocket, the Falcon 9. That rocket’s reusability dramatically dropped the cost to launch, and SpaceX has been absorbing most of the business lately.

Now they could face competition from Relativity Space, who have developed the Terran R, a rocket that is not partially reusable, but fully reusable. If all else is equal, they should be able to provide launch capabilities for even less than SpaceX’s Falcon 9 system.

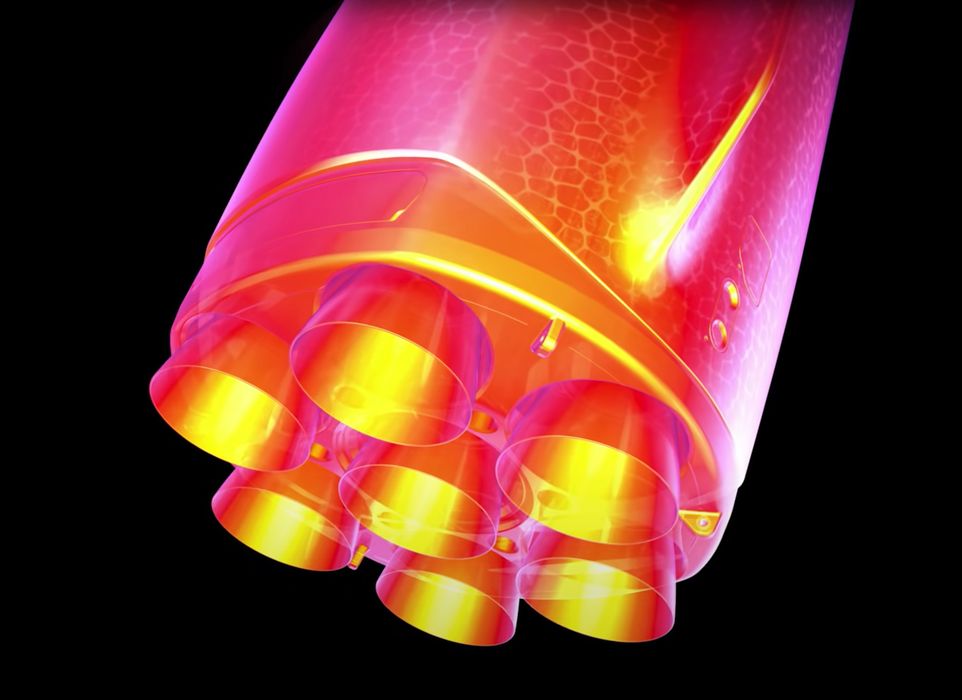

How did Relativity Space achieve this? They built a proprietary metal 3D printing system they call “Stargate” that can, as most 3D printers can do, produce arbitrary objects. The company has used it to produce working Aeon 1 engines for their previous and much smaller rocket, the Terran 1.

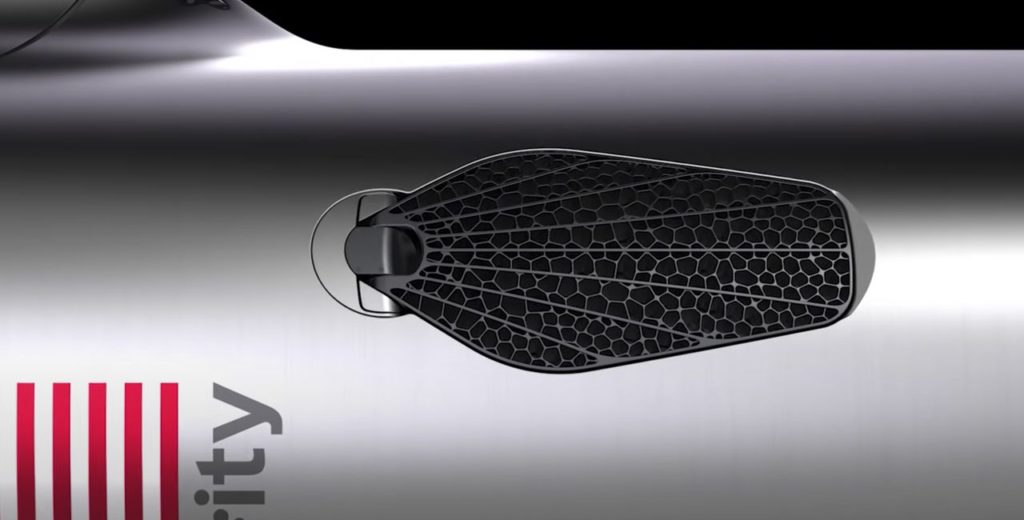

The advantage here is that they are literally 3D printing the entire rocket with Stargate. The engines, the fuselage, plumbing and more. This approach allows them to bypass many complications during the build process and subsequent operation: there are far fewer parts to assemble, fewer joints to fail, fewer seams to leak, and so on. The parts are also designed using generative techniques to ensure they are lightweight as possible.

Other companies in the space have used 3D printing to produce simpler rocket engines, which were extraordinarily complicated to produce using conventional manufacturing processes. However, Relativity Space has taken this concept to the limit by 3D printing not only the engine, but the rest of the rocket itself!

What is the Terran R? Their video explains quite a bit:

There’s a few things to note here, such as the Terran R’s apparent goal of “multiplanetary transport”. There is only one other reusable system targeting that capability, and it’s SpaceX’s Starship, which is currently being developed in Texas.

Unsurprisingly, the 3D printed Terran R’s design seems eerily similar to Starship: stainless steel fuselage, two stage system, grid fins, and more. It seems Relativity Space may have been inspired by Starship concepts.

It is unclear how Relativity Space will produce the Terran R in practical terms. For example, the height of the Terran R stages seem far higher than the images of Stargate that we’ve seen: 66m when stacked together. Perhaps they will add a “Z-axis” elevation system to the machine so that it can 3D print at higher and higher levels?

Relativity Space said the Terran R will have a massive payload of up to 20,000 kg to low Earth orbit, which is likely when used in reusable mode. To contrast, SpaceX’s Falcon 9 has a payload of 22,800 kg, again in reusable mode. This could be shaping up as big competition for SpaceX, which has flown well over 100 missions with the Falcon 9 thus far.

On the other hand, Relativity Space is well behind SpaceX; they have not even launched their previous system, the Terran 1, yet let alone near a launch of the new Terran R concept.

What’s important to know here is that we have a “relatively” new company that’s been able to leverage 3D printing so strongly that they now are in a position to rival an established competitor.

Via Relativity Space