Charles R. Goulding and Kellen Coleman discuss the revolutionary application of 3D printing in medicine, exemplified by the creation of prosthetic skull pieces.

The world of medicine is witnessing a remarkable transformation, thanks to the innovative applications of 3D printing technology. One of the most intriguing developments in this field is the use of 3D printing to create prosthetic skull pieces embedded with acrylic windows for real-time brain monitoring. This breakthrough, highlighted in a recent New York Times article, is just one example of how 3D printing is revolutionizing the medical field.

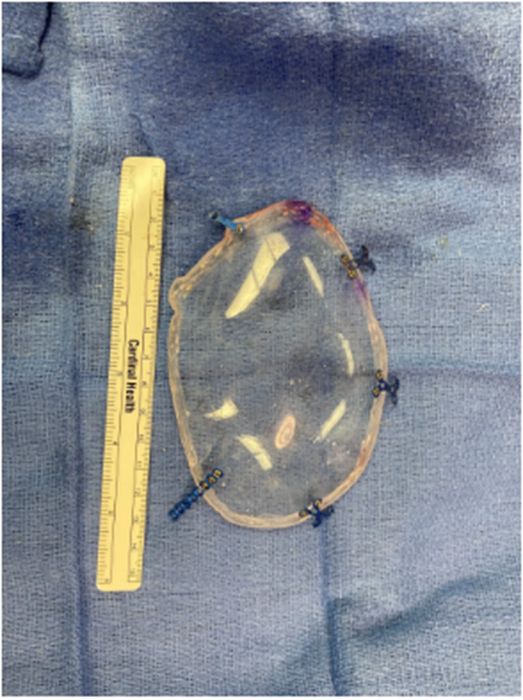

The New York Times article sheds light on how 3D printing is changing the way we treat and monitor brain-related conditions. In cases where patients require a piece of their skull to be removed due to brain injuries, tumors, or other issues, traditional methods of restoration were costly and carried a high risk of infection. However, 3D printing has introduced a groundbreaking solution.

Patients like Tucker Marr have received prosthetic skull pieces with embedded acrylic windows, allowing doctors to use ultrasound for real-time brain monitoring. This technology reduces the need for expensive and time-consuming CT scans or MRI scans, providing immediate insights into the patient’s brain health.

The medical community is excited about the potential of 3D-printed prosthetic skull pieces with acrylic windows. Dr. Mark Luciano’s study at Johns Hopkins, involving 37 patients, found no risk of infection over a year. However, challenges remain, including the need to improve ultrasound image quality and ensure long-term safety. Some experts, like Dr. Ian McCutcheon, advocate for rigorous clinical trials to validate ultrasound’s accuracy compared to traditional imaging methods.

Beyond neurosurgery 3D printing has found myriad applications in the medical field:

Customized Implants: 3D printing allows for the creation of personalized implants tailored to an individual’s unique anatomy. This includes everything from orthopedic implants for joint replacements to dental implants and even custom-made prosthetic limbs.

Surgical Planning: Surgeons can use 3D-printed models of patient’s organs or body parts for precise surgical planning. These models help doctors better understand the patient’s condition and optimize their approach, reducing risks during surgery.

Drug Delivery systems: 3D printing enables the creation of intricate drug delivery systems, where medications can be tailored to release at specific rates or in precise locations within the body. This can improve treatment efficacy and reduce side effects.

Bioprinting: The future of medicine may involve bioprinting, where living tissue and even organs can be 3D printed. While still in its experimental stages, this technology holds incredible promise for addressing the organ shortage crisis and advancing regenerative medicine.

In the case of Jared Hager, 3D printing not only restored a missing piece of his skull but also paved the way for groundbreaking research. Researchers at the University of Southern California are exploring the use of ultrasound, made possible by these acrylic windows, to study brain activity. The hope is to detect subtle signals from changes in blood flow in different parts of the brain as patients perform various activities, which could provide unprecedented insights into brain functions.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Credits.

Conclusion

Medical 3D printing is not just about technology; it’s about enhancing patient care, improving outcomes, and pushing the boundaries of what’s possible in healthcare. As this field continues to evolve and innovate, we can look forward to more stories like Tucker Marr’s and Jared Hager’s, where 3D printing plays a pivotal role in transforming lives and the practice of medicine.