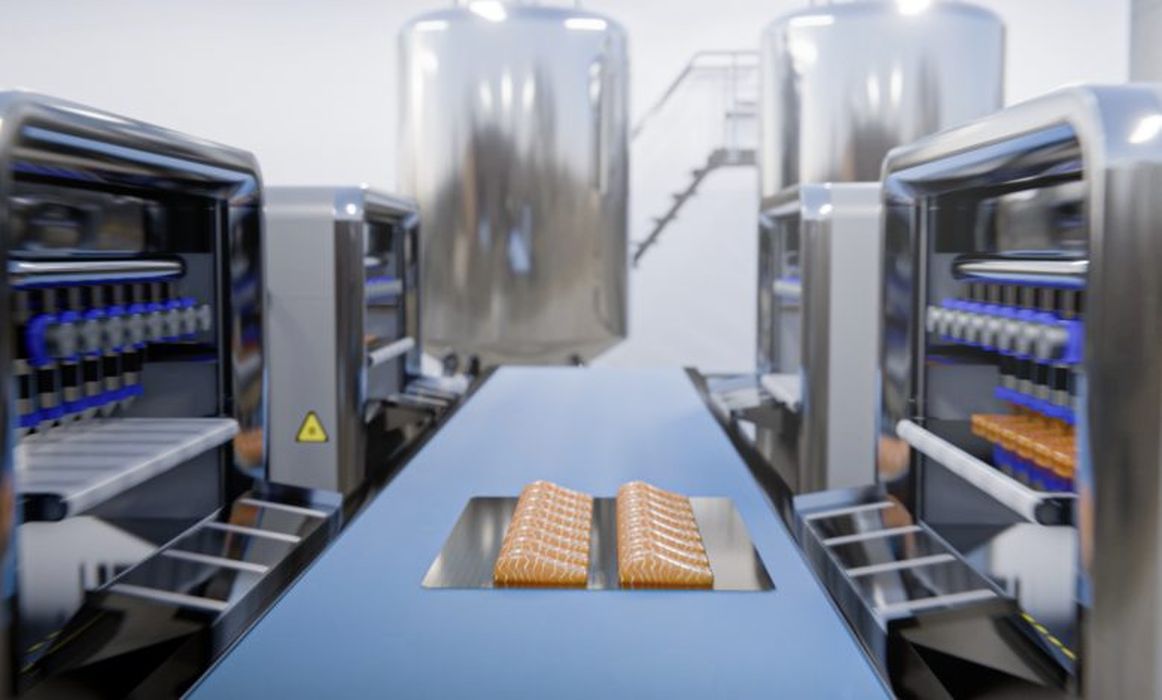

Enabling new 3D printed food categories such authentic whole-cut meat alternatives and products with customized shapes, structures or textures.

Austrian Food-Tech startup Revo Foods presented the Food Fabricator X2, the world’s first industrial production method for 3D printed foods, setting a milestone in food manufacturing innovation. The 3D process enables new product categories for the first time, such as authentic whole-cut meat alternatives or products with customized shapes, structures, or textures. Revo Foods is scaling up the production capacity through 2024 and opened up the first public investment opportunity into the project.

Industrialization of 3D Food Printing

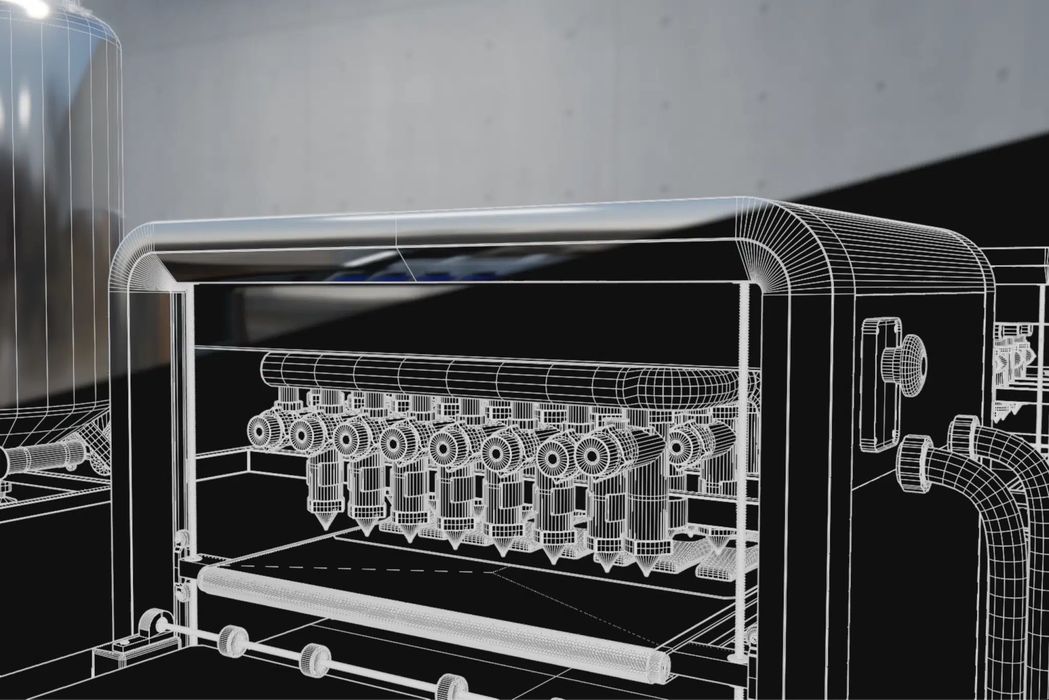

The Food Fabricator X2 features a novel multi-nozzle system that enables continuous food production, marking the first time that mass production of products is possible with 3D food printing technology.

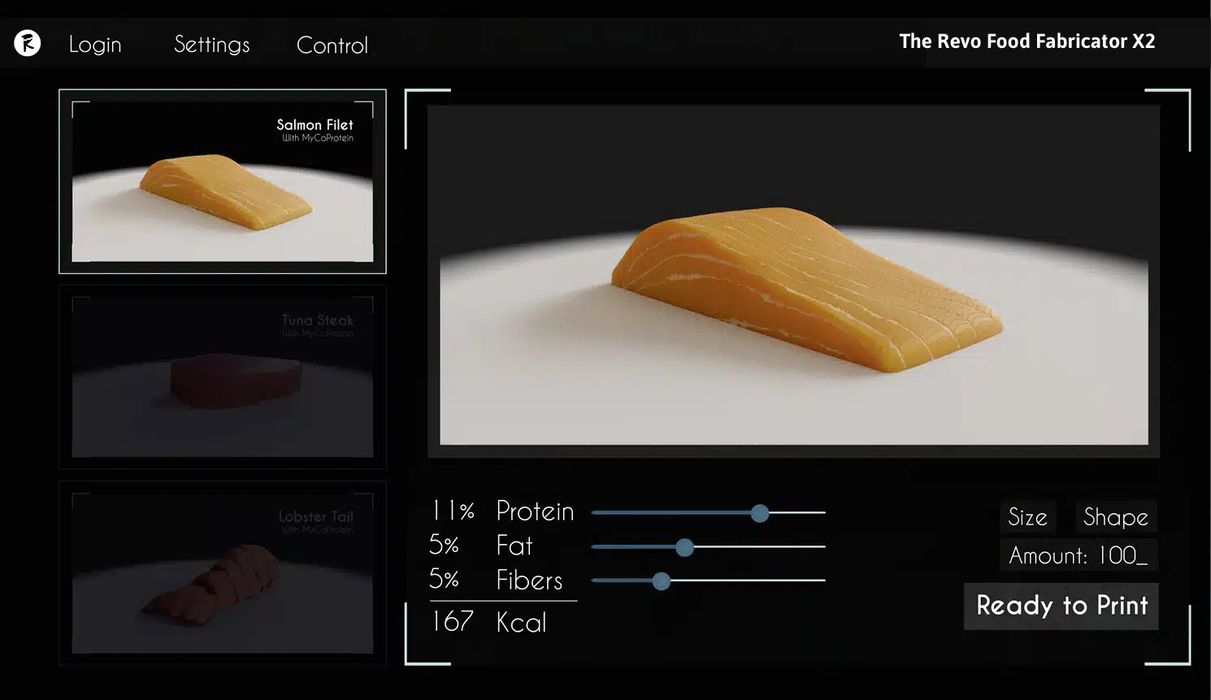

Using a high-precision extrusion system, different ingredients can be combined in any predefined structure, enabling the production of previously “impossible” products. This means that new food categories such as authentic meat alternatives or products with innovative structures, shapes or textures can now be produced at large scale. This technology enables the new food industry segment of “mass customization” for the first time, meaning the flexible control of product parameters such as sizes, shapes, materials or texture, without the need for hardware adjustments during the process.

Digitalization of the Food Industry

As an Industry 4.0 production method, 3D food printing opens up new opportunities in the conventional food industry through digitization: the technology makes it possible to react flexibly to demand, produce different products in small batches and avoid food waste in small batches and avoid food waste in production.

3D printing technology enables a completely new approach to creative product development and food production. One new area of application is the customization of texture palettes for plant-based meat alternatives. The controlled integration of a fat component into a plant-based protein fiber matrix is essential for whole-cut meat alternatives such as steaks or fish filets but has not yet been achievable with any other technology at a large scale, until now.

“3D food printing on an industrial level allows us to change the way we think about food. Products that were previously very exclusive and more likely to be found in gourmet restaurants can now be produced on a large scale. I am excited about the new creative opportunities that open up to food product developers with the help of this technology,” said Dr Robin Simsa, CEO of Revo Foods GmbH.

Opportunity to Join Revo Foods

As a proof of technology, THE FILET – Inspired by Salmon was produced in September 2023, using this technology for the first time (Revo FFX1), marking the first scale-up of this 3D printing system. This salmon filet alternative based on mycoprotein was the first 3D printed food available in supermarkets and has confirmed that there is a high interest of consumers and retailers in this technology.

To increase production capacity and meet demand, Revo Foods is now announcing its first public investment opportunity in the form of digital company shares. With this capital, the first stage of upscaling will be completed over the next two years (2024 – 2025). Revo Foods plans to expand production capacity in two additional major upscaling steps.

An investment in Revo Foods is possible from January 18 to April 18, 2024. At the start of the first public investment round, the company has already raised €435,000, underlining the public interest in the new technology and the company’s mission. Investments in Revo Foods are made via the Germany-based green-tech investment platform FunderNation.

Read the rest of this story at VoxelMatters