Zortrax has stepped up to the plate with a high-speed 3D printing upgrade.

Over the years, the company has spawned multiple models of 3D printers. However, a high-speed model had been noticeably absent from their portfolio. Until now, that is.

Introducing the “Zortrax Speed Mode”, an upgrade that’s now available for their M200 Plus, M300 Plus, and M300 Dual 3D printers.

Zortrax elucidates, “As a response to our community’s expectations, Zortrax engineers have developed a new feature thanks to which Zortrax FDM 3D printers can work with an increased printing speed within the new Speed Mode. What we wanted to deliver was a completely free feature which our customers could use right away with no need to buy additional spare parts or dedicated kits. All they have to do to take advantage of the new printing mode is update the firmware in their 3D printer with the latest version, which is ready for download at the Zortrax Support Center from today.”

Tripling the Speed with a Firmware Upgrade

With this new feature, these three printer models can crank out objects up to three times faster than their standard speeds.

This maneuver by Zortrax, while intriguing, doesn’t exactly come as a surprise. The competition is hot on their heels, hustling to pump out high-speed 3D printers, all juiced up by the groundbreaking firmware technology of input shaping. This feature ensures more precise motion system control, compensating for vibrations caused by swift movements. This has been a staple in Klipper firmware and has also been announced for Marlin, the most favored 3D printer firmware.

A couple of things about this announcement pique my curiosity.

The Curious Case of Zortrax’s Speed Upgrade

Firstly, Zortrax Speed is a freebie! No charges for this upgrade; it’s just a firmware update.

This brings us to the second curiosity: it’s purely firmware. Typically, high-speed 3D printers see changes in two areas: the motion system and the hot end. If you’re gunning the printer at a higher speed, the motion system mechanics must hold up without triggering excessive vibration that even input shaping can’t rectify.

Zortrax must have assessed their existing motion systems and deemed them fit for higher speed operations.

As for the hot end, the filament cruises through it much quicker, leaving less time for the filament to soften. Hence, many high-speed 3D printers employ a lengthier hot end to allow for more melt time. Zortrax hasn’t followed suit but does recommend raising the extrusion temperature by up to 5C as a workaround. I’m skeptical about this working across the board.

Due to these uncertainties, the claim of a 3X higher speed might not be feasible for each and every print job. Sure, print speeds might increase, but the higher you climb, the higher the chance of compromised print quality. The optimal results would come from a 3D printer purpose-built for high-speed operations. Were these Zortrax models designed with this in mind?

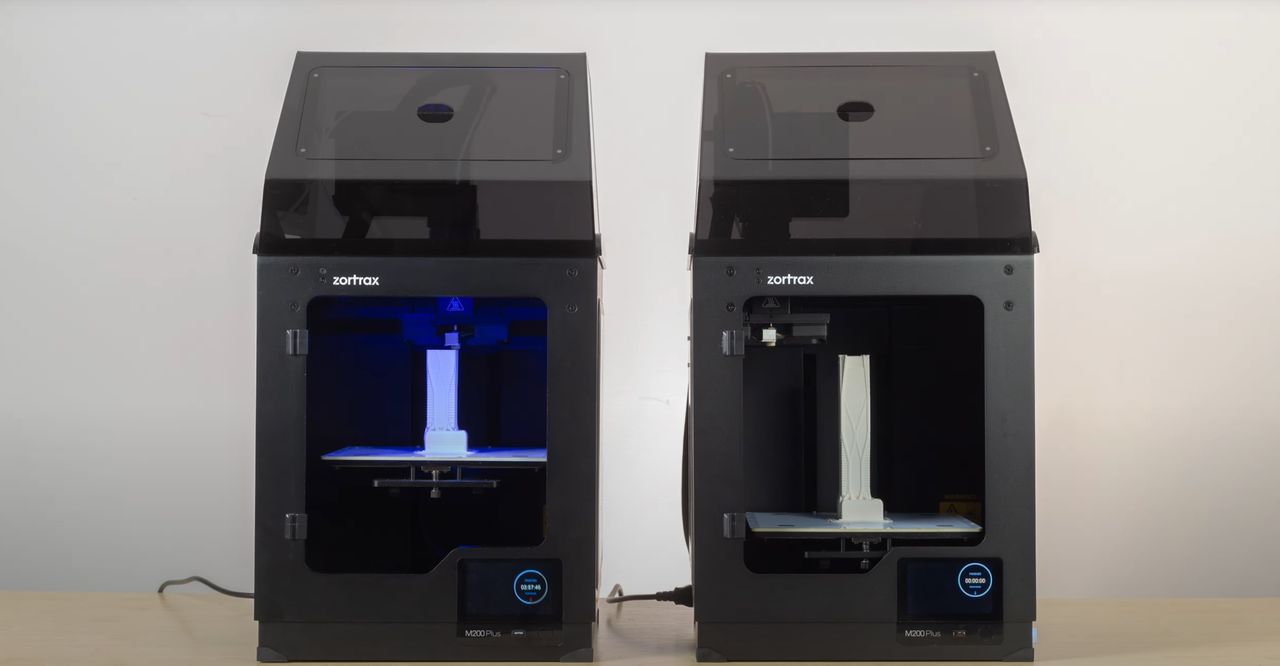

Here we see a comparison of a print made using high speed mode and without. From the image, it appears they are quite similar in quality. But will the be the case for every print?

Zortrax High Speed Strategy

From a strategic perspective, this move by Zortrax is a no-brainer. No hardware changes are necessary, and it instantly sweetens the deal for existing customers and possibly draws in those on the hunt for faster printers.

My hunch is that this could be Zortrax’s counterpunch to Bambu Lab’s sensational launch of their budget-friendly high-speed 3D printers. With several other companies swiftly launching higher-speed devices to compete, Zortrax’s move could very well be their answer to Bambu Labs.

Via Zortrax