Essentium released the results of their annual survey of manufacturing leaders.

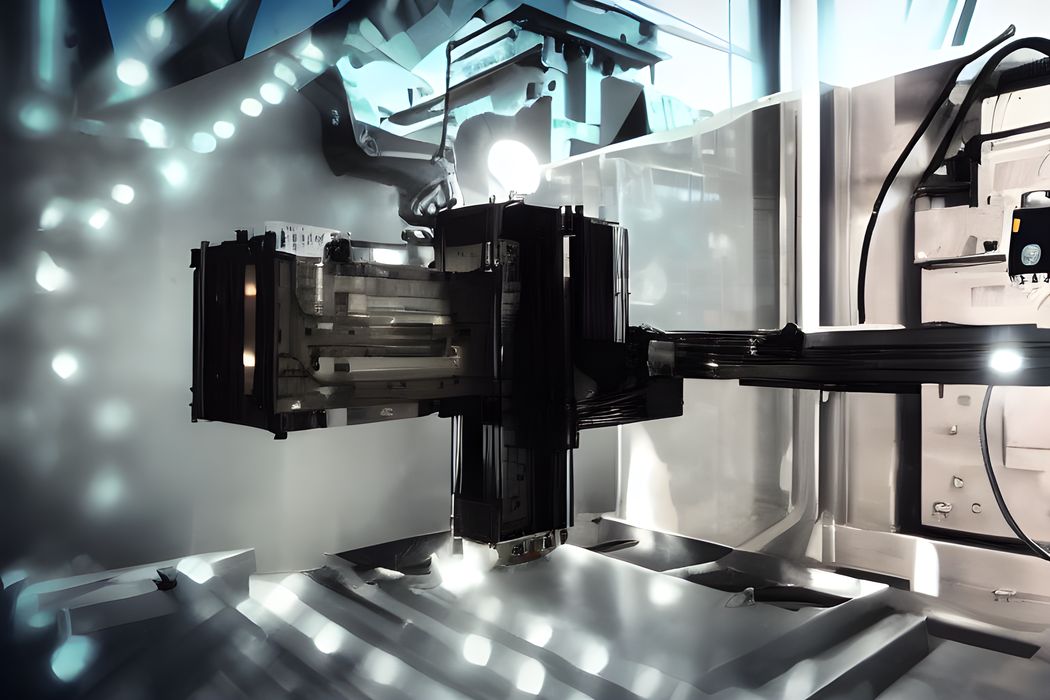

The company has been conducting this type of survey for several years, and by doing so, they can gain a better understanding of the feelings and intentions of the manufacturing industry. Essentium has long focused on the manufacturing market, having developed high-speed equipment, industrial materials, and most notably, processes and certifications that ease the path to additive manufacturing for organizations.

The survey’s results are, in a way, not too surprising, but quite dramatic when viewed in the long term.

For example, the survey results show that:

“95% of the respondents expect a significant increase in the use of AM technology in the next three to five years, with 41% of leaders projecting a dramatic surge.”

That isn’t too surprising, given the incredible progress of the technology in the past couple of years. The addition of high-speed equipment along with true engineering materials that can be used for end-use production parts opened up many possibilities.

What is surprising is how this sentiment has shifted. Years ago, the idea of 95% of manufacturers expecting major use of AM would have been ridiculous. Back then, it was challenging for any 3D printer producer to persuade a manufacturer to “try” 3D printing equipment.

However, certain brave companies pushed through the barriers and demonstrated the value by leveraging the technology. New, lightweight parts created by complex CAD software can be easily produced on the equipment. Those companies with the technology have an advantage, while those without do not.

Hence the 95%.

Incredibly, some 85% of respondents reported positive sentiment from their company leadership, with half indicating their management was “very positive.” This is extremely good news for 3D printer manufacturers, who otherwise might have been blocked by upper management from making paths into new client organizations.

Finally, the most interesting finding was all about materials. Essentium writes:

“The study results indicate that manufacturers are particularly focused on using certified materials that meet or exceed existing standards, a critical factor for industries like aerospace, medical, military, and automotive. A staggering 99% of the manufacturing leaders surveyed agreed on the importance of using certified materials for large-scale manufacturing, with 80% saying it was ‘very important’ or ‘critically important.'”

This is a message to the 3D printing industry: if you hope to break into the manufacturing market, you absolutely must have a strong portfolio of certified engineering materials.

The reason for this is that manufacturers expect consistency: they cannot produce quality products if the input materials are “variable.” By certifying a material, the manufacturer can tune the print settings for the highest quality without the risk of messing up if the chemistry of the material changes in subsequent batches.

This is one of the reasons we continue to see partnerships between equipment manufacturers and chemical producers: it’s very important.

It’s possible to access the full survey results, but you will have to provide your contact information on Essentium’s form.

Via Essentium