Satori is to launch a new “6K” resin 3D printer in coming weeks.

The London-based startup has been working on resin equipment since they emerged last year. Their initial focus was on the dental market, although their equipment can be used for a variety of applications.

Satori Collaboration

Since launch, they’ve collaborated with a number of artists seeking ways to leverage 3D printing in ways the artists were unable to achieve on their own. One notable collaboration occurred last year when Satori worked with noted 3D artist Ganit Goldstein to produce LED-powered 3D prints.

It turns out that Satori learned something important while engaging in these repeated collaborations: artists want to 3D print larger items.

Certainly additional build volume would allow artists more space for their creations, which could get even more complex at a larger scale. Thus Satori set out to develop a bigger 3D printer.

The key element of the new machine, called the Satori VL2800 is its light engine, which appears to be unique in the industry.

Satori 6K

Most MSLA machines make use of commercial LCD panels to mask out light and produce the selective polymerization on each layer. For many years that meant using standard 2560 x 1600 pixel elements. However, that also means your X-Y resolution is precisely 2560 x 1600 pixels.

In the past year or so, many manufacturers have begun switching to 4K LCD panels, which are now less expensive. These provide 3840 x 2160 pixels, creating more resolution. Depending on the physical size of the panel, you can determine the precise size of each solidified pixel if used in a 3D printer.

The problem is that if you were to make a 4K panel physically bigger, you’d reduce the resolution because those same pixels would be spread over a larger surface area.

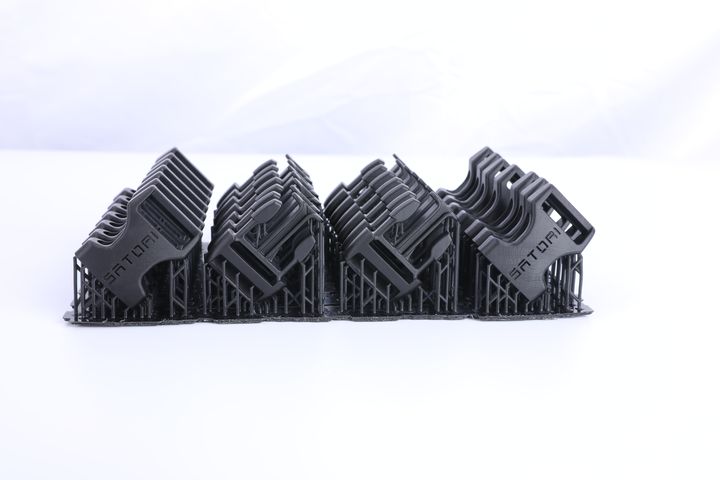

Now that issues seems to be solved as Satori explained the VL2800 uses a 6K monochrome panel, with an incredible 5448 x 3060 array of pixels. That has enabled them to expand the machine’s build volume to a massive 278 x 165 x 300 mm. That must be one of the largest desktop MSLA build volumes available, and because of the 6K light engine, you still get excellent print quality with 50 micron resolution.

With that volume you can print some truly huge items. Here’s an example of a bicycling helmet, entirely 3D printed in one piece:

Satori VL2800 Features

Satori has engineered the VL2800 to consistently produce high-quality output through the use of several features. One is the high-end Z-axis motion system, which is a separately obtained module from a Taiwanese supplier rather than the typical build-it-yourself approach of other 3D printers.

The VL2800 also includes a closed-loop feedback system. This is a series of sensors that allows the machine to adjust itself on the fly if it detects things are not as they should be. That alone should dramatically increase print quality.

In a conversation with Chengxi Wang, Satori CEO, I asked about manufacturing, as Satori is a small startup without their own factories. Wang explained they’ve partnered with well-known 3D printer manufacturer Elegoo to perform contract manufacturing.

However, this is not what you might be thinking: white labeling of one of Elegoo’s devices. Instead, Wang explained that the machine has entirely been designed by Satori engineers from their London office from the ground up. Wang noted that their team includes two key engineers that have decades of 3D print experience in a number of companies and that they have the knowledge to develop systems such as the VL2800.

The VL2800 is a striking machine, having a different color scheme than you’d expect for a resin 3D printer. Most resin machines have a base and an orange translucent cover to stop UV rays, and they’ve become almost indistinguishable from each other. Instead of following that path, Wang explained they decided on an enclosed cabinet style with a white color. The machine includes an interior lighting system to enable easy viewing of ongoing operations.

Wang said they are still working on a wash and cure solution, but there are plenty of others already on the market. However, one would have to consider the very large size of prints coming from the VL2800 when selecting a wash and cure station from a third party.

Can you purchase a VL2800? Not quite yet. Wang told me they intend on launching the product via Kickstarter in several weeks, where they will be able to tell the full story of this interesting 3D printer.

Via Satori