Seurat landed a truly massive 3D printing partnership.

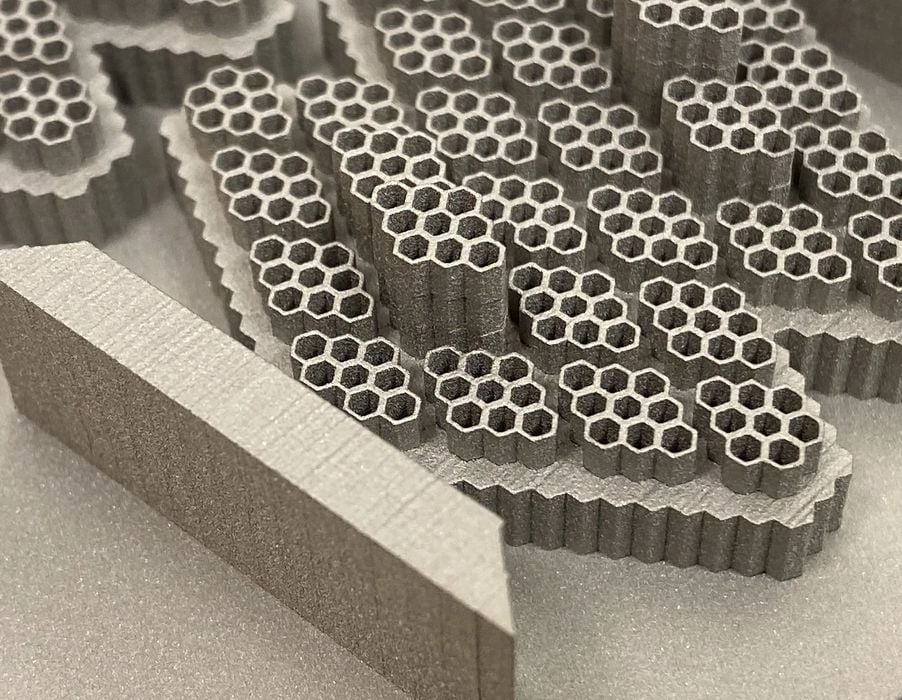

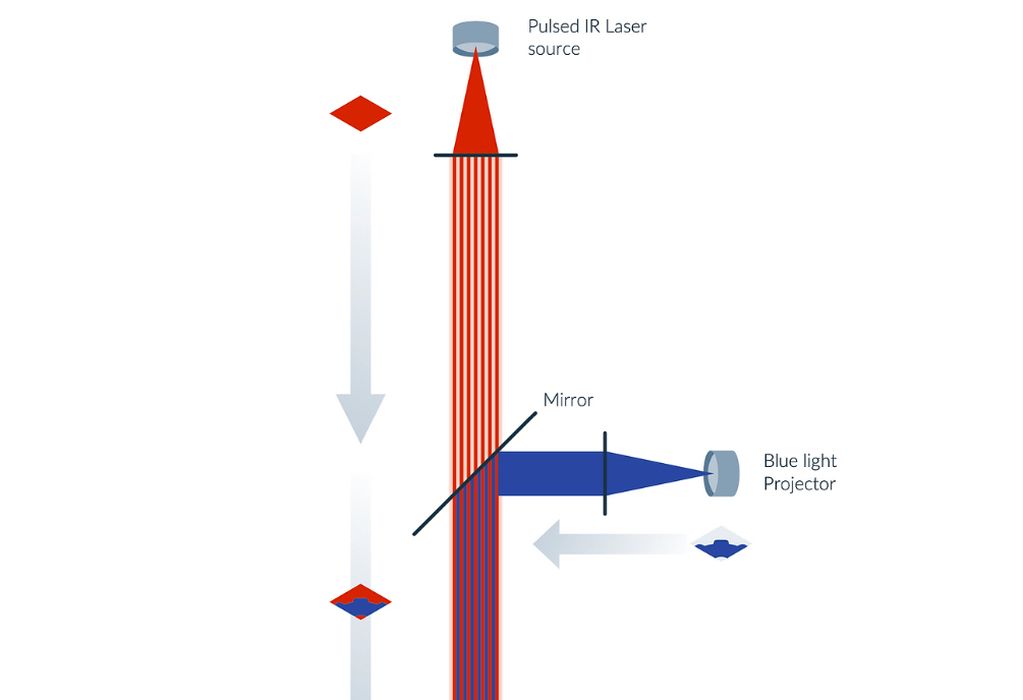

Boston-based company Seurat has developed a unique, energy-friendly 3D printing process that we’ve covered previously. Their proprietary process is somewhat similar to standard LPBF 3D printing, where a laser selectively fuses layers of fine metal powder. However, the biggest difference lies in the laser system.

Area Printing: A Game-Changer in Speed and Scalability

In Seurat’s “Area Printing,” the laser source is shaped using complex optics to generate a square illumination field. This area then becomes the active spot that has between 10-20 “dots” per mm within that space. This area can quickly move about the print surface in a checkerboard style to rapidly complete an entire layer.

While other high-speed LPBF systems might employ four (or twelve) lasers for added speed, Area Printing is basically using the equivalent of hundreds within their active area. The result is a massive gain in speed. What’s more, Area Printing is scalable, making it possible to print larger objects with the technology.

Seurat’s Business Model and Customer Orders

Seurat has chosen to operate as a kind of service, keeping the equipment in-house where they can operate it with highly experienced techs and continually upgrade it, rather than selling machines to the public. Such an operation depends on customer orders, and Seurat has had many orders. But none quite like this.

Partnership with Siemens Energy

Siemens Energy has partnered with Seurat to produce an astonishing 59 tons of 3D printed metal parts over the next six years. That might be one of the largest (by weight) orders for AM parts in history. This partnership will provide Seurat with considerable and consistent revenue over the next few years and demonstrates the scalability of their technology in a very real manner.

Sustainability and Future Possibilities

Seurat’s Area Printing is a highly efficient process that uses only green energy, meaning that the 59 tons of parts will generate little CO2 during their creation. Seurat explained that development will ramp up over a six-year period for parts meeting the material qualification requirements of Siemens Energy. The initial focus will be on one part family, with the possibility of increasing volumes to include others in the future.

It’s worth noting that Siemens Energy is an investor in Seurat (as are others) by means of their venture arm. This partnership shows the company’s confidence in Seurat: they have both invested AND bought significant services from them.

If Seurat can land several more deals of this type, they will undoubtedly become one of the leaders in metal AM production.

Via Seurat