SPONSORED CONTENT

Creality now offers no less than six different Ender-3 3D printer models, and choosing between them can be challenging.

Creality announced the new Ender “Neo” series recently, and it’s added quite a few more models to their 3D printer product line. The new Neo models include:

- The Ender-3 Neo

- The Ender-3 V2 Neo

- The Ender-3 Max Neo

But hold on, Creality previously announced “S1” models:

- The Ender-3 S1

- The Ender-3 S1 Pro

- The Ender-3 S1 Plus

With now six models of the very popular Ender-3 desktop 3D printer offered by Creality, it is getting more difficult to choose between them.

Choosing a 3D printer really depends on two factors: what you intend on making, and your budget level. Fortunately, the latest Ender-3 machines are all relatively low cost.

All current Ender-3 machines have similarities, such as automated leveling using the CR-Touch sensor, 32-bit controller board, silent stepper motors drivers, power loss handling, and handy knobs to adjust belt tension. The key to choosing an Ender-3, however, is in the differences between the devices.

Ender-3 Extrusion Technology

The most fundamental difference you must understand is that the Neo and S1 lines differ in extrusion technology. The Neo series uses Bowden extruders, while the S1 series uses Direct extruders.

While we’ve previously published a detailed comparison of these two extrusion methods, let’s briefly provide an overview here.

In a Bowden system, the extruder motor and gears are outside the build volume, and push the filament through a long PTFE tube to the hot end, where material is softened and deposited.

In a Direct system, the extruder motor is mounted on top of the hot end in the build volume right on the toolhead. It moves along with the deposition, and pushes the filament a very short distance right into the hot end.

Bowden systems have lightweight toolheads, meaning it’s possible they can move more rapidly and print quickly. On the other hand, Direct systems are more easily able to handle a wider variety of materials, particularly flexible filaments, which could jam when pushed through a PTFE tube.

The S1 series, like Ender-3 S1 Pro and Ender-3 S1 Plus has the “Sprite” hot end, which is also “all metal”. This means it is able to accommodate certain 3D print materials that require higher softening temperatures. The Neo series does not have an all metal hot end, and so has somewhat fewer material options.

The bottom line here is that operators seeking a machine with more varied material capability should consider the S1 series. For those simply 3D printing objects with basic materials, the Neo series should be more than sufficient.

Ender-3 Mechanicals

While all six machines have relatively similar mechanical structures, there are some differences.

The S1 series uses dual threaded rods to guide the Z-axis up and down. For the Neo series, only the Ender-3 Max Neo includes dual-rail Z-axis. While both printer lines should produce good results, the S1 series could at time offer better print quality due to this added hardware.

Ender-3 Build Volume

Another consideration is build volume. Let’s look at the build volumes of the various Neo and S1 machines:

- Ender-3 Neo – 220 x 220 x 250 mm

- Ender-3 V2 Neo – 220 x 220 x 250 mm

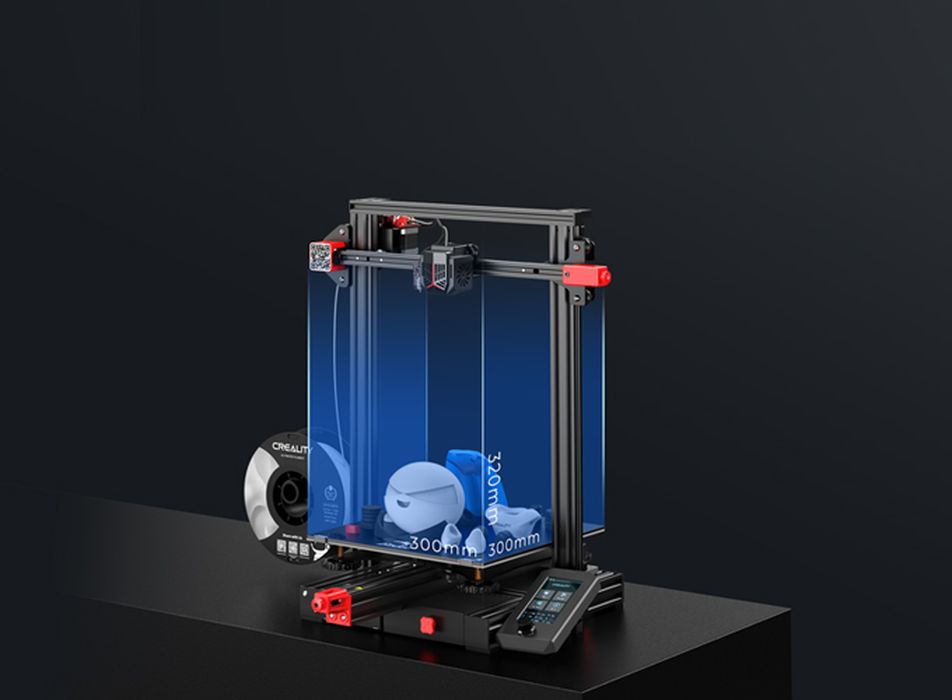

- Ender-3 Neo Max – 300 x 300 x 320 mm

- Ender-3 S1 – 220 x 220 x 270 mm

- Ender-3 S1 Pro – 220 x 220 x 270 mm

- Ender-3 S1 Plus – 300 x 300 x 300 mm

See the pattern here? The machines all have about the same build volume, except that the Neo Max and S1 Plus have a larger build volume.

If an operator seeks a machine that can produce larger objects, then those two devices should be of interest.

Often a large build volume is not required, because there are relatively few objects exceeding 250mm in any dimension. However, for some operators this is a critical requirement and thus points them at the two larger Creality Ender-3 options.

Ender-3 Filament Sensor

A filament sensor is a special gadget that detects when the filament runs out. This signals the 3D printer to pause printing, and alerts the operator to deal with the problem.

Usually this happens when the end of a spool’s filament is encountered, or if the filament happens to break. It’s an incredibly valuable function for long prints, because without it the printer will continue “printing air” and the print will be a failure.

This sensor is present on all Ender-3 models, except for the Ender-3 Neo and Ender-3 V2 Neo.

Operators looking to 3D print long jobs might want to ensure they select an Ender-3 model with a filament out sensor.

Ender-3 Print Adhesion

Two methods of print adhesion are used on the latest Ender-3 models.

Carborundum glass is used on the Ender-3 Neo and Ender-3 Max Neo, while a spring steel magnetically attached plate is used on all other models.

Generally, the magnetic plate is a bit easier to use, but doesn’t provide a perfectly flat bottom to prints that is done by the glass plate. For most operators, this won’t make a big difference.

Ender-3 Control Panel

All current Ender-3 models except the Ender-3 Neo include a 4.3” control panel, and these machines use the latest easy-to-use interface developed by Creality. This is far superior to the typical “rows of letters” interface provided by most Marlin systems.

There is a slight difference between the Ender-3 models, however:

The Ender-3 Neo uses a monochrome panel; all others are color

The Neo series and Ender-3 S1 use a rotating knob for operator input

The Ender-3 S1 Pro and Ender-3 S1 Plus use a touch screen

For some, the touchscreen is easier to use, but the knob interface is also easy to use once you get a feel for it.

Ender-3 Pricing

There is quite a price range on the Ender-3 series. List prices are as follows:

- Ender-3 Neo – From US$219

- Ender-3 V2 Neo – From US$299

- Ender-3 Neo Max – From US$369

- Ender-3 S1 – From US$399

- Ender-3 S1 Pro – From US$479

- Ender-3 S1 Plus – From US$529

If you’re read the differences between the machines as above, you’ll quickly realize that the pricing rises as build volume and functionality increases. The more you spend, the more you get.

All machines are available now from store.creality.com in the United States and at store.creality.com/de in European countries, and there are apparently discounts currently in place on some machines.

Choosing an Ender-3

After reading the material above, the steps required to choose a machine would involve asking these questions:

- What is my budget?

- What is the size of the largest item I might ever want to print?

- Do I want to print in flexible or other unusual materials?

- Will I frequently print long jobs?

- Do I need a touchscreen or is a knob interface sufficient?

If you have the answers to these questions, it’s easy to select an Ender-3 from Creality’s lineup of six different machines.

Via Creality