Stratasys announced a new carbon fiber material for use in their F123 series 3D printers.

Carbon fiber is rapidly gaining in popularity for use in 3D printers in recent years, and there’s good reason for this.

Typically, a “carbon fiber” filament material is actually a mix of chopped carbon fibers and a polymer. Continuous carbon fibers are extremely strong, but require specialized 3D printers equipped with spools to lay down these long fibers during 3D printing. Instead, many opt for using chopped carbon fiber filaments that provide less strong results, but still far stronger than the base polymers.

Stratasys has now announced “FDM ABS-CF10”, which uses ABS as the binding polymer, and ten percent chopped carbon fiber. The lengths of the chopped fibers are very small, small enough to easily pass through the hot end’s nozzle without issue.

There are plenty “CF” filaments on the market today, but this is the first one that Stratasys offers for use on their F123 series. This is important because this equipment is not open materials, and thus you can use only the materials offered by Stratasys. Up until now that didn’t include a CF option, unless you had one of their higher-end machines, like the Fortus 380mc Carbon Fiber Edition.

The F123 series is a lower-cost option as compared to the company’s Fortus line, so this announcement opens up the F123 equipment to CF materials.

I’m certain this will be welcomed by F123 operators, as CF parts are notably stronger than those made from “plain” polymers. Stratasys said:

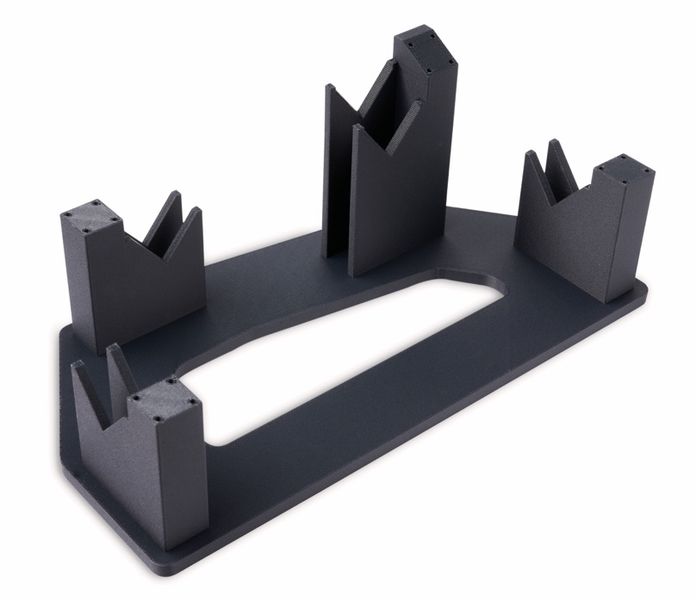

“The material properties of FDM ABS-CF10, featuring 10% chopped carbon fiber, make it a compelling alternative to metal parts. In fact, the material is 15% stronger and more than 50% stiffer than standard ABS, without the weight of metal, and can be printed with a high degree of accuracy. QSR Support™ water-soluble material makes it possible to 3D print intricate and complex parts without time-consuming manual support removal.”

Having done some CF parts printing myself, I can foresee how this may play out. F123 operators will try the CF material and discover the same effects I did: the parts are significantly stronger with little to no additional fuss in printing, and at only a moderate cost increase for materials.

The benefits are so tremendous it might be that CF materials become a defacto standard for generic 3D printed parts in the near future.

If you haven’t tried CF 3D printing materials yet, you should — but be sure to have at least a hardened steel nozzle to avoid having the abrasive CF material erode your nozzle. The parts are just a lot better.

And for those operating F123 3D printers, you can now do exactly the same thing.

Via Stratasys