Formlabs announced a new resin for their dental 3D printing portfolio, making it an even more powerful option for dentists.

Formlabs has been aggressively pursuing the profitable dental 3D printing market for several years now. But addressing a market is not as simple as slapping a label on your equipment and trying to sell it to a new group of users.

Formlabs has undertaken considerable effort to delve into the end-user applications in the dental area. They’ve identified multiple use cases and developed materials and processes to specifically meet their needs.

This announcement is about a new material for another commonly used dental process, indirect bonding trays, which are used to simplify orthodontic bracket placement.

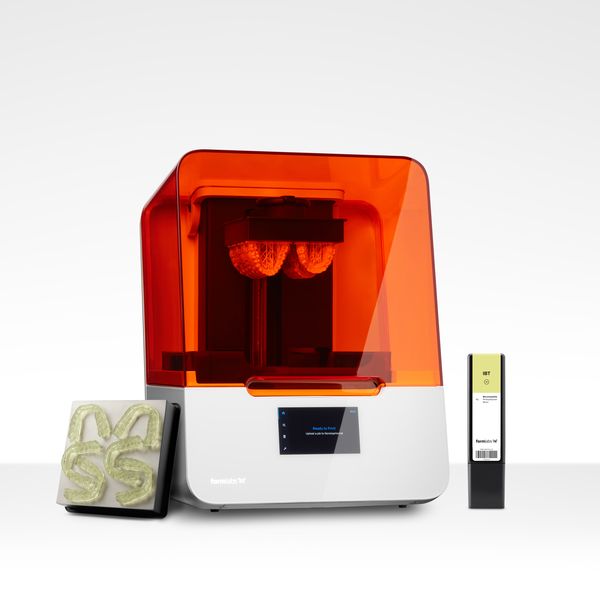

IBT resin allows for direct 3D printing of these bonding trays right in the dentist’s office. The dentist can generate a customized 3D model from patient data in only minutes, and can then trigger production of the part on their Formlabs Form 3B dental 3D printer.

Formlabs said:

“An indirect bonding tray is a custom-made appliance that precisely matches each patient’s dentition and bracket prescription to place multiple brackets at once. Since the preparation and careful placement can be done in advance virtually, patient chair time can be cut in half, saving the orthodontist valuable time.”

Formlabs says their IBT Resin has several advantages over competing resins:

- Enhanced color for clear visualization of brackets against teeth: No-fuss chairside use with less error.

- Finished appliances that are tasteless, odorless, and not sticky: Comfortable experience for the patient: Minimal support material needed

- No need for glycerin or nitrogen post-curing: Easy and hassle-free post-processing.

This biocompatible resin joins several other highly-specialized resins in Formlabs’ dental portfolio. For dentists considering acquiring 3D printing equipment, Formlabs’ already-low cost equipment was attractive, but as they continue to add materials and function directly to the dental process, their options are compelling.

This venture by Formlabs to me is an outstanding example of how 3D printing will gradually evolve in the future: addressing highly specific markets with a combination of equipment, materials and process. There’s little room for generic 3D printers in industry when specialized solutions can be literally dropped into a business and provide immediate value.

Via Formlabs