Desktop Metal and ExOne have announced breakthroughs this week in binder jetting capabilities for aluminum.

Aluminum is a popular material in manufacturing, particularly in industries like automotive and aerospace where every ounce matters. The additive manufacturing industry has been seeing increased interest in working with the material. Recent materials announcements from Aurora Labs and ECKART TLS focus on the importance of metallurgical powders including aluminum. And now two major collaborations in binder jetting are yielding breakthroughs for 3D printing 6061 aluminum.

Desktop Metal x Uniformity Labs

Desktop metal and Uniformity Labs have been working together for some years now and have now announced “a breakthrough powder that enables aluminum sintering for binder jetting AM technology.” They explain:

“This new powder is the result of a multi-year collaboration between the companies to develop a low-cost, raw material yielding fully dense, sinterable 6061 aluminum with greater than ten percent (10%) elongation and improved yield strength (YS) and ultimate tensile strength (UTS) versus wrought 6061 aluminum with comparable heat treatment.”

And:

“This new powder enables the sintering of unadulterated 6061 aluminum and represents a significant improvement over prior techniques used to sinter aluminum, which required coating powder particles, mixing sintering aids into powder, using binders containing expensive nanoparticles, or adding metals such as lead, tin and magnesium. Critically, the powder also enables compatibility with water-based binders and has a higher minimum ignition energy (MIE) relative to other commercially available 6061 aluminum powders, resulting in an improved safety profile. Desktop Metal and Uniformity Labs plan to continue to work together over the coming year to qualify the powder and scale production for commercial release. Once fully qualified, Uniformity 6061 aluminum will be available for use with the Desktop Metal Production System platform…”

Of the importance of the work, Desktop Metal Co-Founder and CEO Ric Fulop explains:

“This breakthrough represents a major milestone in the development of aluminum for binder jetting and a significant step forward for the AM industry as it is one of the most sought-after materials for use in automotive, aerospace and consumer electronics. The global aluminum castings market is more than $50 billion per year, and it is ripe for disruption with binder jetting AM solutions. These are the best reported properties we are aware of for a sintered 6061 aluminum powder, and we are excited to make this material available exclusively to Desktop Metal customers as part of our ongoing partnership with Uniformity Labs.”

ExOne x Ford

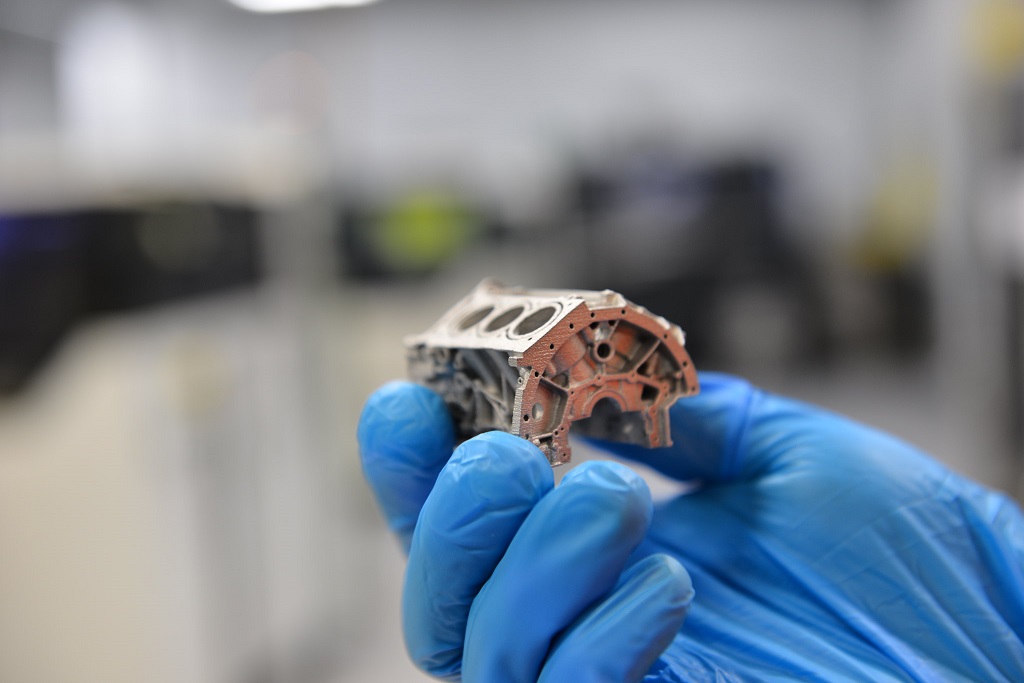

Another project, in progress since 2019, has been co-funded by ExOne and Ford Motor Company. These teams have “developed a patent-pending process for rapid and reliable binder jet 3D printing and sintering of aluminum that delivers properties comparable to die casting.” This release explains:

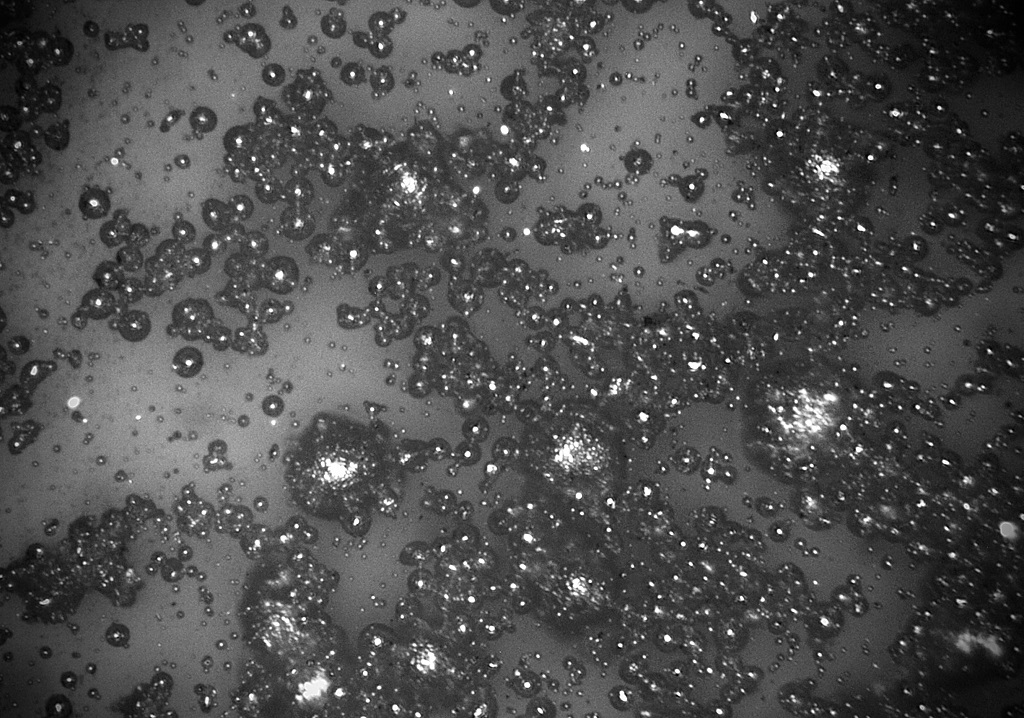

“The new innovation came about through the process of binder jetting, widely regarded as the fastest method of metal 3D printing for high-volume output. It uses a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand, or ceramic to create a solid part, one thin layer at a time. When printing metals, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object. The heating process reinforces the strength and integrity of the metal, and while the process for sintering stainless steel is well understood, achieving high densities greater than 99 percent is an industry breakthrough for aluminum.”

And:

“Delivering a commercially viable achievement in this area has evaded researchers for more than a decade. Collaborative and individual patents are expected to be filed by Ford and ExOne as a result of this ongoing project.”

Ford Technical Leader for Additive Manufacturing Harold Sears adds:

“This is a breakthrough in making 3D printed and sintered parts for the auto industry. While the 3D-printing process is very different than stamping body panels, we understand the behavior of aluminum better today, as well as its value in light-weighting vehicles. High-speed aluminum 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to do complex parts with aluminum that previously weren’t possible. It’s really opening doors for other opportunities.”

Aluminum Binder Jetting

The two announcements were released within hours of one another. Long-term work on advancing aluminum capabilities for binder jetting technology shows the broad demand for this material for this technology.

It’s also notable that both Desktop Metal and ExOne worked with external partners to develop their new solutions. The different approaches are also interesting; while Uniformity Labs focuses on AM-specific material and software solutions, Ford is an end user. Ford and ExOne trace their relationship back to the early part of the new millennium. Ford was an early adopter of 3D printing in general, and now houses a wide range of technologies across its global facilities. Its first ExOne purchases, in the early 2000s, were “several of ExOne’s first industrial sand 3D printers in the United States to create sand molds and cores for metal casting,” this week’s release reminds us.

Both Desktop Metal and ExOne continue to expand their binder jetting material portfolios with proven materials. For its part, ExOne’s binder jetting portfolio now comprises 23 metal, ceramic, and sand materials qualified for use on the company’s systems. Aluminum brings the single-alloy metal count up to an even dozen options, and ExOne adds that titanium is also “now fast-tracked for qualification in partnership with a global medical device company.”

Via Desktop Metal and ExOne