New research shows a method of greatly simplifying future volumetric 3D printers.

Volumetric 3D Printing

You might not be familiar with the term “volumetric 3D printing“. It’s a new form of 3D printing that uses photopolymer resin as many current 3D printers do, but in quite a different manner.

The concept is essentially the reverse of a CT scan. A CT scan fires X-Rays through a patient at different angles. These successive images are then compiled into a 3D model. In volumetric 3D printing we start with the 3D model and computationally generate the light patterns that one might have obtained when CT scanning.

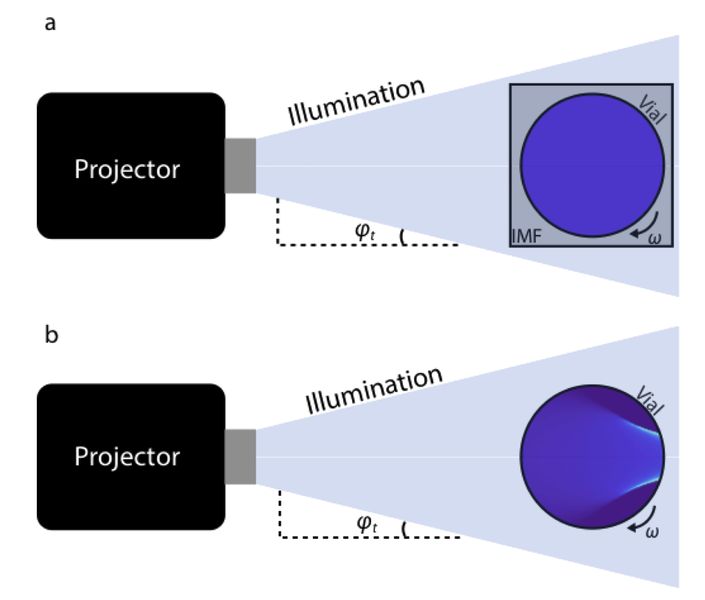

These light patterns are fired at a transparent, rotating, cylindrical vat of photopolymer resin, where the object gradually forms as resin solidifies. Note that the vat spins at a constant rate, and the projections quickly shift from one 2D view to another so rapidly that it is essentially a continuous 3D build process. It’s not a layer-by-layer process; it’s beyond that.

The benefit of volumetric 3D printing is that the structures can form far more rapidly. Instead of, for example, waiting for a laser to tediously trace all solid portions of the object, a volumetric approach more-or-less forms the object in 3D simultaneously. In theory you can 3D print objects much more rapidly, perhaps as much as 100X faster.

Volumetric 3D Printing Challenges

There are some issues with volumetric 3D printing, such as the constraint of using transparent resin, but there’s another one that causes volumetric 3D printers to be more expensive.

It has to do with the light projections. These must pass through the transparent surface of the build chamber to reach the desired points in 3D space within the resin. However, the curved vat surface distorts the projection.

That’s a problem, because distorted light patterns would solidify material in the wrong places, leading to a failed 3D print.

To correct for this distortion, volumetric 3D printers have had to employ fancy optical systems that account for the distortion before projecting into the build chamber. This allows correct solidification to occur.

Sometimes this correction is provided by an “index matching fluid” surrounding the build chamber, or an optical lens system.

Ray Distortion Correction

Now Canadian scientists have developed an approach to avoid this problem entirely.

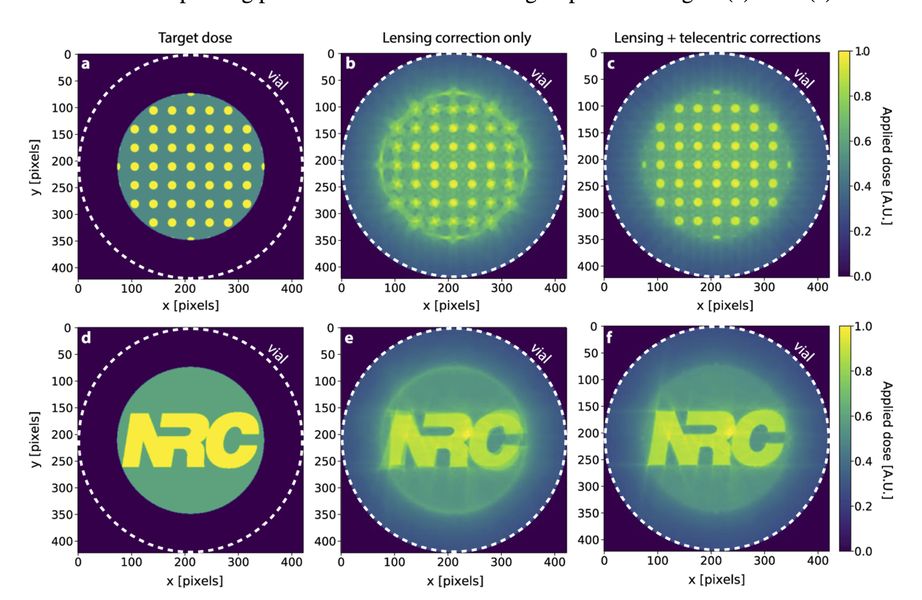

Their approach is to computationally correct the projections before projection occurs. In other words, they distort each 2D projection frame in just a way to account for the vat distortion.

Why is this important? The answer is simple: it means you do not have to have a fancy optical system in the volumetric 3D printer.

Using this approach, volumetric 3D printers would be correspondingly less expensive to build because the price of precision optics is quite high. This research just eliminated an entire component previously required by volumetric 3D printers.

There is complex math involved in this computative correction, but it is not unlike ray-tracing that is commonly performed for 3D rendering.

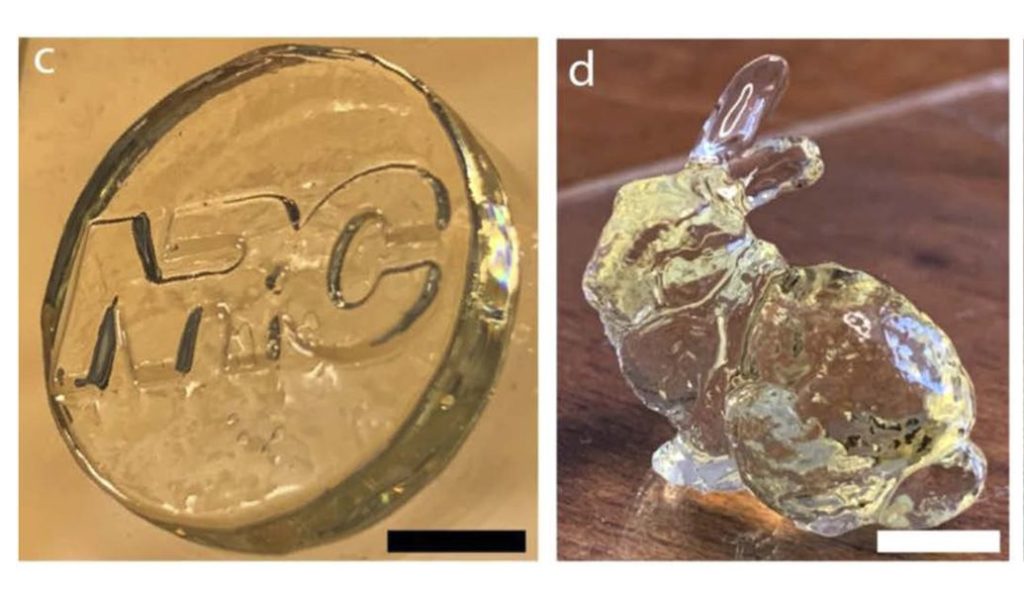

The researchers were able to implement a demonstration of their approach using a projection configuration, and successfully 3D printed several objects, including the Stanford Bunny.

Based on that demonstration, it’s likely this technology will make its way into either existing volumetric 3D printer projects, or entirely new projects yet to emerge.

Either way, we’re likely to see lower cost, very rapid volumetric 3D printing in the near future.

Via OSA