I dropped by Tethon 3D’s stand at Formnext and had a chat about their new ceramic 3D printing resin.

The company, based in Omaha, has long been one of the most innovative suppliers of unusual 3D printing resins. They’ve focused on ceramic materials, and today they market quite a variety of unusual resins, including stoneware, porcelain, earthenware, mullite and others. I suspect they are the only source for such ceramic resins on the planet.

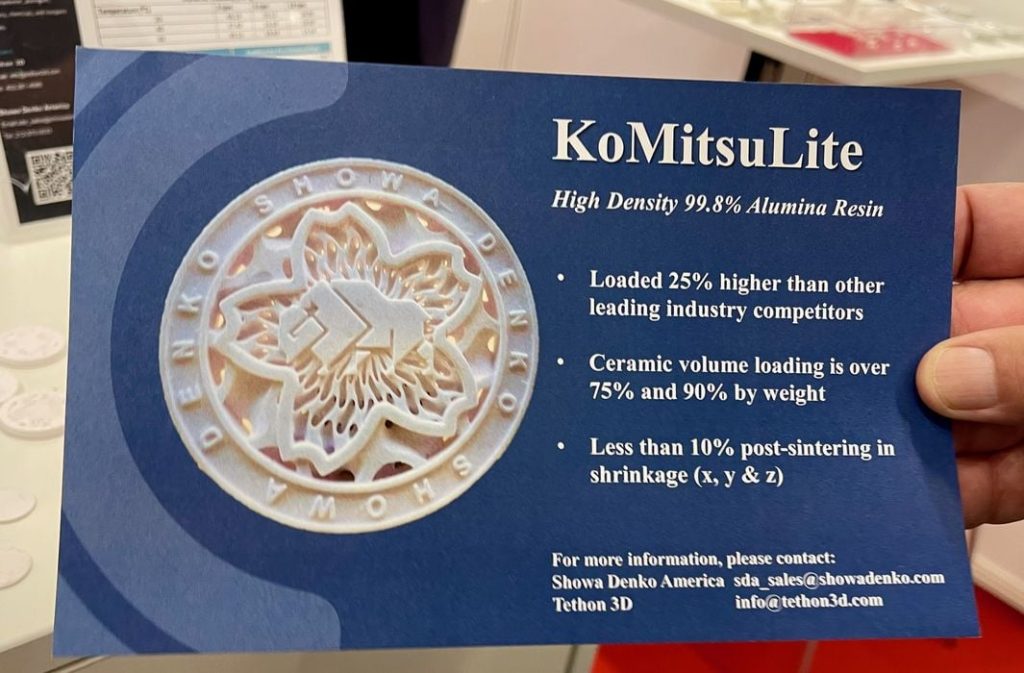

Now they’re introducing a very interesting new material called “KoMitsu Lite”. It’s based on an existing material from a Tethon 3D partner that’s now been reformulated to be usable as 3D printer resin.

The key property of this resin is hard to believe: it’s 99.8% alumina resin. In other words, only 0.2% of it is NOT alumina.

I was skeptical, but was asked to lift a bottle of this stuff. My goodness, it was incredibly heavy, almost like lifting a rock.

Because it basically IS A ROCK. It’s 99.8% alumina.

I was shown a few 3D prints made from this incredibly dense material, and was quite impressed. This detailed vase was made with the material on Tethon 3D’s Bison 1000 3D printer.

Another very interesting characteristic of KoMitsu Lite is that it doesn’t shrink very much: only eight percent. Typically ceramic prints made with Tethon 3D resin will shrink around twelve percent.

This is unsurprising when you think about it: there is only 0.2% non alumina in the print to be taken out, so there’s not a lot of room for shrinkage.

There’s one catch with this material: you must 3D print it on Tethon 3D’s Bison 1000 resin 3D printer. The reason for doing so is that this unusual material requires extremely precise conditions to print successfully, such as a heated bed to specific temperatures, which is a feature offered by the Bison 1000.

I am quite impressed by this material design because it clearly pushes the envelope of resin technology almost as far as it can go. With this ridiculous density of material, one can only imagine what other kinds of materials could be made in this way.

Via Tethon 3D