When it comes to surgical models, the idea is to pick the right 3D printer for the job.

3D printed surgical models were first used some years ago, when surgeons planning highly complex surgeries realized there could be an advantage to using 3D printing technology.

Surgical models are 3D representations of the anatomical structures in a particular area of the patient, typically the zone where the surgery is to take place, or the path to it through the body.

In the distant past surgeons had to rely solely on their anatomical knowledge of the human body and figure things out as they proceeded through the operation. There were few good approaches for “seeing” into the patient ahead of time aside from X-rays, which show only solid structures like bone. For soft tissue, experience with cadavers and prior operations would have been quite valuable.

But with the advent of computer technology, surgeons were able to construct and use digital models of the operation site to gain familiarity before the actual operation took place.

Then most recently, the idea of 3D printing surgical models arose. In this approach the scanned soft tissues are 3D printed in segments or in whole, and provided to the surgeons. They examine the structural scenario in tactile 3D in order to not only familiarize themselves with the site, but also to plan different strategies for the procedure.

Since then the practice of 3D printing surgical models has been a profitable niche for some companies in the space.

But it turns out there is quite a spectrum of 3D printable surgical models available.

Initial 3D printed surgical models were simply a solid, mono-material 3D print of a tissue structure. But then we saw the introduction of multi-material approaches, where some portions of the surgical model could be made with different materials or colors to help identify them to the surgeons.

Things got a lot more complex when modern full-color 3D printing technology was applied to the problem. Stratasys’ J-series offers multi-material and multicolor capabilities, including the ability to 3D print soft material. This technology has been used to 3D print highly realistic surgical models, which have likely greatly assisted surgeons in their work. In fact, Stratasys even has a “digital anatomy” strategy.

This progression from plain solid models to lifelike 3D prints has been remarkable, and my thought had been that this is the natural sequence one might expect. Increasingly better and more realistic 3D models would be the path to follow.

Or is it?

The other week BCN3D presented a case study of a client in Argentina who has been using their equipment to produce surgical models. They said:

“In Argentina, Dr Gustavo Nari has collaborated with engineering company Mirai3D to create biomedical models that significantly improve his surgical planning process thanks to the IDEX technology of his BCN3D Sigmax 3D printer.”

Hold on, how could this be true? Don’t we always want the best and most realistic 3D prints for our surgical models? BCN3D’s FFF equipment is not capable of full-color, multi-material, realistic soft 3D prints. Why is this happening?

BCN3D said:

“Hospital Transito Caceres de Allende’s Dr. Gustavo Nari has teamed up with Mirai3D: a biomedical engineering startup that focuses its efforts on 3D printing, virtual reality, and advanced materials in the healthcare sector. Enlisting the help of the IDEX technology in a BCN3D Sigmax, they are creating biomodels to design surgical plans for a better anatomical understanding of clinical cases. Dr. Nari is experiencing first-hand the wonders this can bring to surgical procedures from start to finish.”

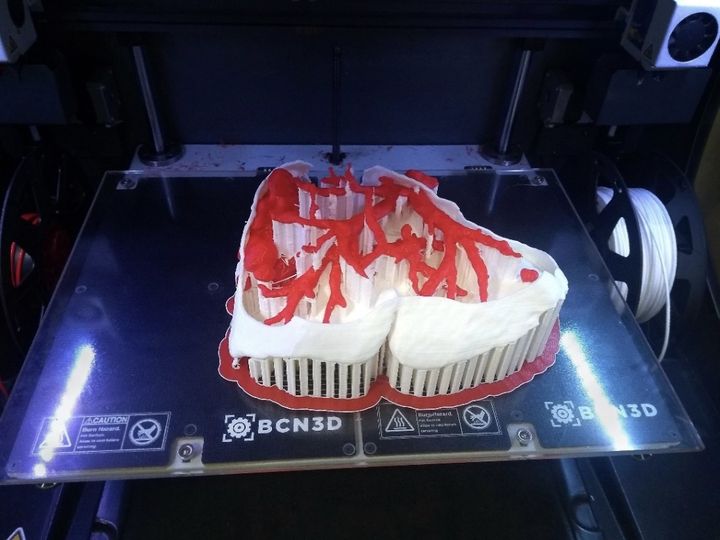

They produce these models through X-ray scan data and the dual-material capabilities of the BCN3D equipment. At top you can see an example of one of these 3D models, which is clearly a lot less sophisticated than one could obtain from a Stratasys J850 full-color 3D printer.

BCN3D explains how they produce these 3D models and how the medical professionals make use of them:

“Combining X-rays and 3D printing technology allows doctors to use scans of the patient to produce a virtual model of the area of interest. This model can then be printed according to lifelike dimensions and sizings. IDEX technology is particularly advantageous here, as the model can be printed in different materials, to replicate different parts of the body such as bones or tissue. IDEX technology can also be used for a variety of colours, giving doctors a visual aid of the different areas. This means more training for doctors to build on their knowledge and have a thorough grasp on case-specific facts.”

After reading this, I realized my assumptions had been wrong all along: there is no necessary progression towards higher-quality surgical models.

No, instead the idea instead is that there is a spectrum of capabilities for surgical models covered by a variety of different equipment — at different price levels.

This presents surgeons with options. It turns out that the different scenarios facing surgeons demand different types of solutions. For some procedures it may be most useful to have a full-color lifelike representation from a Stratasys device, but on the other hand, there are procedures where a BCN3D-style solution is perfectly useful.

As always, choose the right tool for the job.

Via BCN3D