Zmorph announced a new device, the Zmorph Fab.

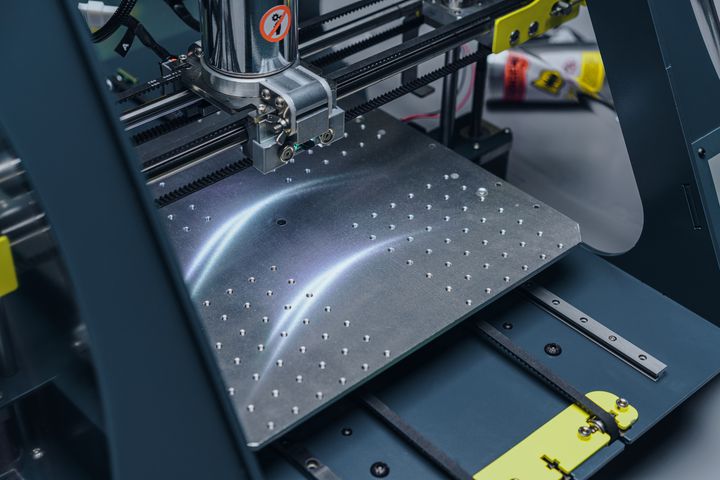

If you’re heard of Zmorph, you’ll know the Polish company produces a tool-changing device that is at the same time a 3D printer, CNC mill and laser engraver/cutter. They’ve produced several versions of this concept over the past few years, and the latest device, the ZMorph Fab, is the most sophisticated yet.

Zmorph says the device “turns your desk into a workshop”, and that’s essentially true. The most common advanced making equipment typically found in a workshop would be a laser cutter, a CNC mill and a 3D printer, and all of these functions are available in the Zmorph Fab. The difference is that the functions are all found within the Fab’s tiny desktop footprint.

How is this accomplished? Zmorph has designed the device’s toolhead to accept rapid swaps. They say you can change the toolhead in 60 seconds or less.

Zmorph Fab Specifications

Let’s look at the specifications — but unlike most 3D printers, there are three different specification sets for this device due to the three toolheads.

First, the 3D printer:

- 1.75mm filament machine that can have either single or dual extruders. This allows use of soluble support for printing complex geometries

- Nozzle temperatures up to 250C, and bed temperatures up to 115C, enabling use of most common materials

- Ability to 3D print PLA, ABS, PET, Nylon, PVA, HIPS, ASA, TPE, PP, PC, PMMA, PC/ABS, including third party filaments

- Generous build volume of 235 x 250 x 165 mm

- Automated calibration, including bed leveling

- Multiple nozzle diameters available: 0.3, 0.4, 0.5, 0.6 mm

- USB, ethernet and SD card connectivity, but no WiFi

These specs make the Zmorph Fab a capable 3D printer with all normally expected features. You don’t want to compromise features because of the presence of other making processes on the device, and it looks like Zmorph hasn’t compromised the design.

For the CNC milling toolhead:

- 300W spindle power

- Milling volume of 235 x 250 x 85 (shorter than 3D print mode due to the toolhead size and length of the router bit)

- Can mill ABS, Nylon, HDPE, PTFE, PC, PP, POM, PMMA, PVC, HIPS, LDPE, PET, Carbon, CCL FR4, Dibond, TCF, Wood, Wood-like, Aluminum, Brass, Copper, Cardboard, Wax, Modeling board, Styrodur

- Cutting speed of between 1-20 mm/sec

- Expected noise level of 70dB

- Materials possible: ABS, Nylon, HDPE, PTFE, PC, PP, POM, PMMA, PVC, HIPS, LDPE, PET, Carbon, CCL FR4, Dibond, TCF, Wood, Wood-like, Aluminum, Brass, Copper, Cardboard, Wax, Modeling board, Styrodur

And for the laser engraver toolhead:

- Spot size: between 0.1 x 0.1 and 0.1 x 0.18 depending on distance

- Laser power of 2.8W

- Laser area of up to 235 x 250 x 85 (shorter than 3D print mode due to the toolhead size)

- Speed of up to 15mm/s

- Materials possible: Wood, Wood-like, Leather, Paper, Cardboard, Felt, Foil, Laminate, EPP, EVA Foam, CCL FR4

The device smartly includes a HEPA/carbon filter to capture emissions from the 3D printer hot end and laser cutting operations. For CNC milling, the enclosed device should capture cut-off bits easily, although they must be cleaned out of the device between jobs to ensure proper operation.

Zmorph Fab Software

Most FFF 3D printers simply use one of the common slicing systems, like Ultimaker Cura, Simplify3D or PrusaSlicer. However, that isn’t really an option with a multi-function device, as those tools don’t handle milling or laser cutting.

Rather than providing three different tools for Zmorph Fab operators, the company has unified all tools in one software package, Voxelizer.

Voxelizer allows the operator to easily prepare jobs for any of the three toolheads and their variants. Zmorph says Voxelizer is:

“Accessible and intuitive user interface is designed for both professionals and first-timers.”

And:

“The all-in-one software for 3D printing, CNC milling, and laser engraving and cutting. All Zmorph toolheads supported. Try the materials presets or work on your own. Voxelizer has an optimized workflow for Zmorph 3D printers ensuring the best and fastest results.”

Who Should Use Zmorph Fab?

Multi-function devices are not for everyone, as needs differ significantly. My thinking is that the Zmorph Fab is likely best for those who really do want to use three different making modes, but do not have space to accommodate separate devices in their workshop.

This could be a personal workshop, or perhaps a cramped lab with limited space available.

As you might suspect, the CNC and laser functions are not as powerful as you would receive on standalone equivalent devices, meaning projects could complete at a bit slower pace. Thus the Zmorph Fab should probably not be used for production purposes.

However, it would serve excellently as an educational platform where someone could easily learn the nuances of not one, but three different making technologies in the same space.

The Zmorph Fab comes in two configurations: the printer alone, at US$3,999 or a bundle, priced at US$4,599 which includes a dual 3D printer extruder and a thick paste extruder.

Via Zmorph