The key to powder 3D printing is not the binder or laser.

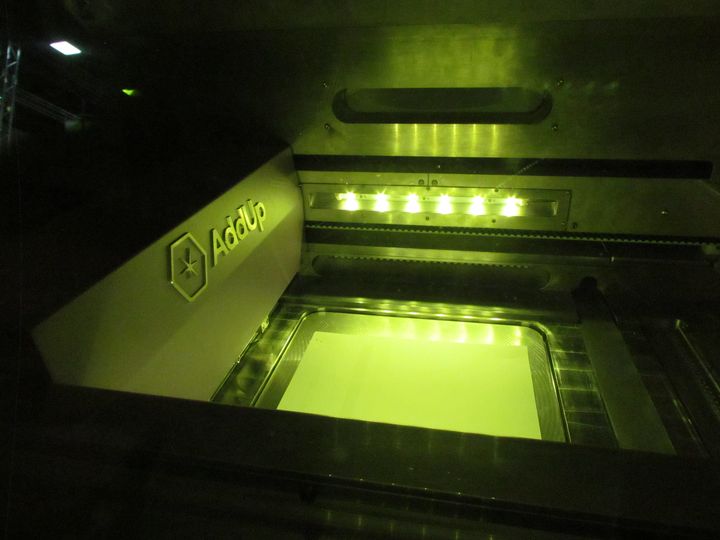

Powder 3D printing is the basis of several popular 3D printing processes, including SLS, LPBF and other variants. In each process the powder is selectively fused by some means, perhaps a high energy laser blast, or droplets of a liquid binder. Layer-by-layer, objects are built in this way.

At first glance the key to these powder processes might be the fusion process. Tune the lasers for optimum heat transfer, shrink the droplets for maximum resolution, increase the motion system speeds, etc.

That’s not it.

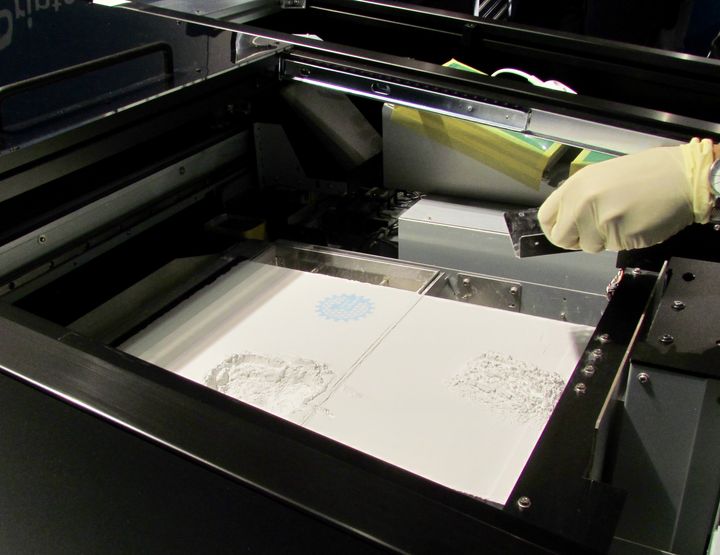

The true foundation of all of these powder systems isn’t the fusion process; instead it’s the process of applying layers of fresh powder, known as “recoating”.

But why is recoating so important? There are several reasons.

First, and perhaps most obviously, if you don’t have a uniformly flat and evenly distributed layer of fresh powder, the print could be corrupted. Imagine if a laser swept an area only to find no powder present. Material on the previous layer might be fused by mistake.

Another possibility is that layers might be too thick in some regions. This may cause a print failure because the laser or binder application assumes a certain depth of material, beyond which fusion may not occur. Thus you may end up with unexpected gaps in a print.

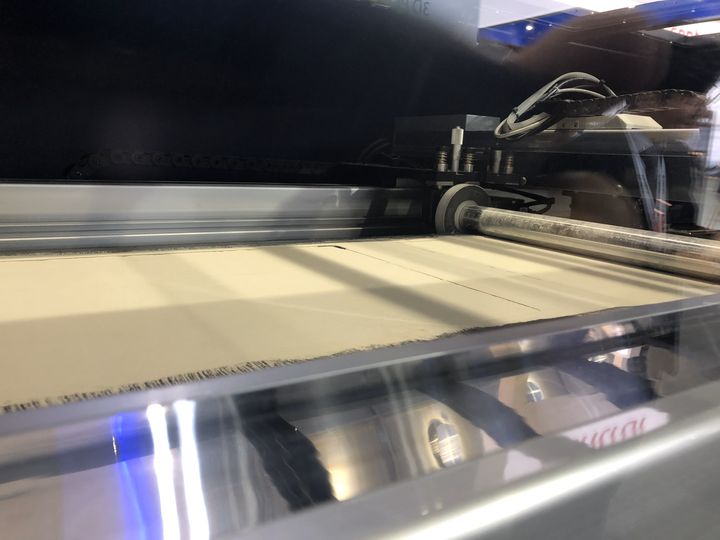

The second reason is speed. While a set of lasers can very rapidly sweep a layer, and a binder jet arm can quickly traverse the entire layer, the print job must still wait for recoating to occur. The recoating is often the slowest portion of the printing process.

If the recoater arm is traveling too fast, then you might get the first problem: uneven powder layers. If it’s too slow you get long print durations.

3D printer manufacturers try their best to balance between speed and reliability, but pushing the envelope can cause specific jobs to fail in practice.

One approach used by several powder printer manufacturers is a two-way recoater. Normally the recoater travels across the bed, and then returns home. But the “return home” takes up valuable time. It can be eliminated if the recoater is able to deposit powder in both directions. This approach can substantially increase overall print speed.

Another issue with recoaters is the method of flattening the deposited powder. Most machines use the “blade” approach, where a sharp edge plows through the lumpy powder hills like a bulldozer.

But the blade concept doesn’t work well for certain types of polymer powders, particularly TPU. In those cases a roller approach works better, but this means you end up with two powder machines, each with a different recoater system.

As you can see, the process of recoating is incredibly complex, even though it may appear straightforward at first. That’s why many manufacturers of powder printing equipment expend effort to devise innovative recoater systems to increase reliability and print speed.

As examples of how recoater technology makes a huge difference, I can point you to two examples. Australia’s Aurora Labs has developed an advanced “parallel recoater” that enables their equipment to 3D print nearly 1 tonne of metal material per day. Meanwhile, VELO3D’s advanced and highly tuned recoating system enables that company’s 3D printers to avoid substantial amounts of metal support materials.

The next time you’re considering a powder 3D printer, take a closer look at the recoater system.