Charles R. Goulding and Preeti Sulibhavi look at the possibilities and risks of using 3D printing to overcome supply chain challenges.

The decision for a manufacturer to produce a particular product is based on several factors. Among them include product demand, component or product parts supply and availability, production capacity and cost.

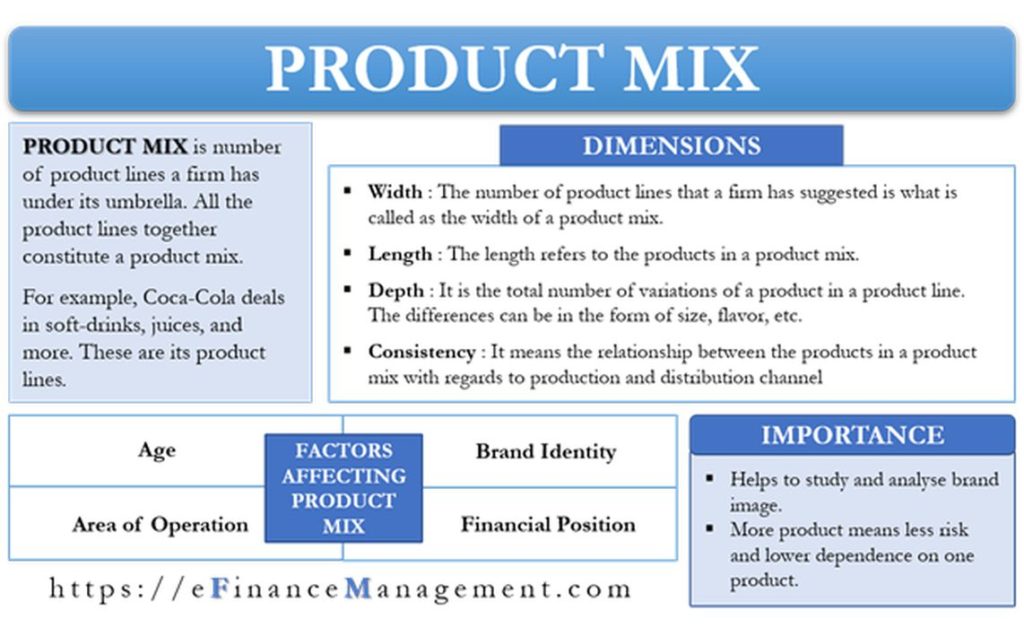

Product Mix and 3D Printing

As the global supply-chain crisis unravels and halts production in a variety of industries by inflating manufacturing and shipping costs, many companies are prioritizing higher-priced products, thereby making budget alternative products/models virtually impossible to find. In fact, manufacturers of products ranging from barbeque grills to garden equipment are pushing production of luxury models of their products, whether it be a kitchen appliance or a Whirlpool washing machine over their affordable product lines.

To cope with a challenging situation, companies can do several things, one of which is 3D printing to create needed components locally and elude supply chain challenges. Although the trend seems to be the suspension of lower-priced goods, that may not be the best solution. For example, some geographic markets include rural areas that may have lower demand for higher-priced products. A manufacturer risks losing distributors in those markets if it cannot provide any product for that particular market demand.

Companies should consider several factors in establishing an optimal product mix, which includes geographic location, local demographics, and sales history. 3D printing is an excellent way of affordably fabricating budget appliances and other items.

There are several examples of this. We have previously written about examples of how 3D printing can resolve certain supply chain issues. Or, how 3D printing can help fabricate replacement parts. They include U.S. Supply Chain Bottlenecks and 3D Printing, 3D Printing for Bus Transportation Critical Repair Parts, and Supply Chain Constraints and 3D Printing. The possibilities are endless for 3D printing affordable models of a wide array of products.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

To maintain a balanced product mix, companies must become innovative. Additive manufacturing/3D printing can be a cost-effective and technologically viable solution to the problem of maintaining product mix during times of supply chain issues. There are many reasons to keep an optimal balance of budget and high-end product items in inventory and 3D printing can help achieve this.