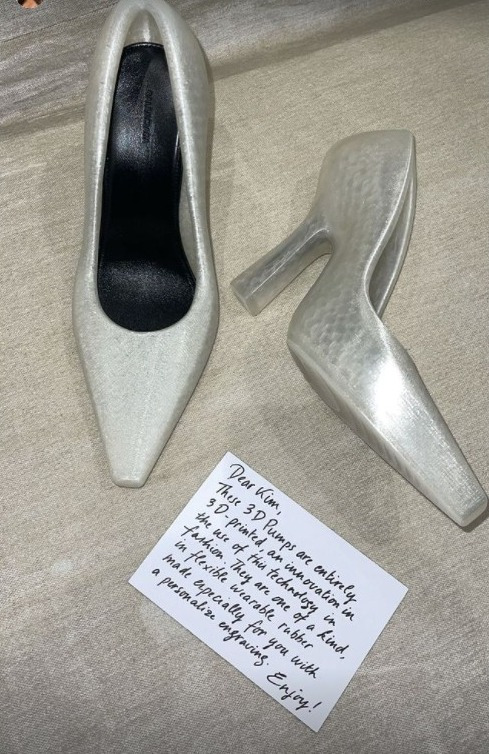

They may look like shoes from an ‘80s Barbie doll, but a lot of technical know-how went into the 3D printed high heels from luxury brand Balenciaga.

The sources for our initial coverage were pretty mainstream, focusing more on the immediately accessible aspects of the story. While “hey, the shoes are 3D printed” certainly came up, more of the focus in tabloids is the price tag. Retailing at $3250, the shoes aren’t really everyday shoes for everyday people. And that’s why they were seen on the Insta feeds of the likes of Kylie Jenner (+ daughter Stormi), Kim Kardashian, and Hailey Baldwin Bieber.

3D Printing Balenciagas

As we reported a few days ago, the Balenciaga site says only of the “3D 110mm Pump in black 3D printed rubber” product details:

3D printed rubber

- Pump

- Pointed toe

- 110mm arch

- Balenciaga logo embossed on the side

- Made in Italy

- Wipe with a soft cloth

“Material: 100% technical polyurethane”

We could see through the layer lines and postulate through the TPU material that the shoes were made using FFF 3D printing technology.

It turns out that Balenciaga had quietly released a video that shows a bit more of the shoes’ design and manufacture, as shared by Italy-based 3D printer company 3ntr:

We can glean a bit more from that very short video, including a look at some familiar 3D printers in action. Further, a source provides information that the pricey shoes aren’t only made of TPU; parts of the shoe are nylon carbon material, 3D printed using both 3ntr and Stratasys equipment. There is also leather covering the inner nylon carbon parts, presumably for comfort and, hopefully, a bit of that “luxury” feel.

We’re also assured that the final design required months of work and testing to come up with a fully wearable shoe.

Why is Balenciaga 3D Printing?

Did this particular high heel design require 3D printing? I mean… look at it. Not really. It’s a relatively simple-looking design that certainly could have been made by traditional means.

The months of iterative work that went into the final design, though, and the fact that as we can see in the video above the shoe is 3D printed in one piece, reveal something else a bit more subtle.

There’s a reason a fashion house like Balenciaga would turn to 3D printing.

For the “cool” factor? Sure, that’s likely. Even Kylie asks Stormi if she knows what 3D printing is, so it’s nice to see some famous folk referencing our humble industry.

However — I spent a little time today digging through Balenciaga’s website to try to see if they had any more publicly available information about the 3D Pumps. They didn’t. But what I did find was interesting.

To be straightforward, I know very little about Balenciaga, or any other high-end luxury fashion brand. That’s not my world. So it was a learning experience to look through a site that includes sections like “50th Couture Collection.”

Two sections stuck out to me: Balenciaga has pages reporting their work with The Trevor Project and their dedication to sustainability.

“Balenciaga is partnering with The Trevor Project in its mission to prevent LGBTQ youth suicide. Fashion can be useful beyond its practical purposes by highlighting important issues like this one.

PROTECTING YOUNG LBGTQ LIVES

For more than 22 years, The Trevor Project has worked to save young LGBTQ lives through 24/7, confidential crisis counseling via phone, text and online chat in the United States. In addition to on-the-ground advocacy, mental health research, and public awareness and education to help youth and adults support the LGBTQ young people in their lives, the organization has invested in international community-building with its TrevorSpace program.

In recent years, many countries have experienced a decline in LGBTQ acceptance. Funds raised through the sale of this Balenciaga product will help address the immediate need for life-affirming peer support for LGBTQ youths. The Trevor Project and TrevorSpace offer safe and scalable solutions that can save lives.

Learn more at TheTrevorProject.org and TrevorSpace.org

For each of this Balenciaga product sold, 15 percent of sales price will be donated to The Trevor Project.”

I included the full text of that page here because it’s nice a) to see the support of a major label to an organization like The Trevor Project, and b) to ensure we share that message as well. Beyond the “nice” of the messaging and financial support, Balenciaga’s work with The Trevor Project highlights that this is a company dedicated to increasing its social campaigns for actionable change. Like in manufacturing.

On the sustainability front, Balenciaga details their approach:

“Aware and convinced of the challenges linked to sustainability, Balenciaga has acted to reduce the environmental impact of its creativity and activity while pursuing progress within fundamentally important social issues.

We are committed to the sustainable and ethical management of our operations. The goal of reducing our environmental impact influences our decisions. At all levels and in all locales—whether at offices and stores or along the supply chain—we respect high standards for social and ecological responsibility. Balenciaga is also fur- and exotic leather-free.”

And their commitment:

“For over one hundred years, Balenciaga has been recognized as a major, unique, and legitimate House in fashion and luxury by offering uncompromising creativity. It is with the same high standards that the House consistently reinvents itself in order to answer the environmental and societal challenges with which we are constantly presented.

Innovation is ultimately experimentation, which is essential to Balenciaga’s creative process as well as how we run our business. Experimentation also creates new unforeseen obstacles that challenge our methods and drives continual evolution. Our goal is to innovate without harming humans or our environment while respecting the welfare of animals. It is through our research and development of materials and manufacturing processes that we are proposing a renewed and responsible fashion system.

Balenciaga is committed to meeting a target of 100% metal-free tanned leather in our collections and to reach 100% alignment with our parent company Kering’sStandards for Raw Materials and Manufacturing Processes by 2025. This ambitious commitment will take several steps. We will regularly update the information on this website for the sake of transparency.”

There are a few keys to highlight here:

- Innovation

- Environmental challenges

- R&D in materials and manufacturing processes

If that doesn’t sound like a call for bringing 3D printing into play, I don’t know what does.

3D printing is also a strong fit for luxury. The still-high costs for many 3D printing applications can be offset in a high-end industry, where customers are already willing and ready to pay a premium. Small-volume production with the capability for mass personalization is also a strong business case for 3D printing, and is exactly in the wheelhouse of luxury.

It’s great to see a company like 3ntr embedding itself into the mission of a luxury brand to 3D print for a more sustainable (and, yes, fashionable) future. The team at 3ntr has told us before that their dedication to a shorter supply chain and focus on growing their markets is keeping them going strong. It could be that we’ll see more 3ntr tech come into play in luxury applications as 3D printing makes the perfect high-end fit.

There is, after all, another familiar name or two (or more!) on 3ntr’s “they print with 3ntr” portion of their site:

Luxury is certainly a market category to keep watching for 3D printing to take off as more style houses take notice of the technology. When they’ll let the companies providing those technologies talk about all that’s happening behind the couture silk curtains, though, is anyone’s guess.

Via Balenciaga, LinkedIn, and 3ntr