Micron-scale 3D printing brings a tiny take to big celebrations as Microlight3D unveils the tiniest Statue of Liberty.

It’s only fitting that the company, based in France, would replicate a French gift to the US on this celebratory Inauguration Day. The 2021 version has, though, been substantially scaled down from the 1886 original. So scaled down, in fact, the print substrate was a penny.

Microlight3D

Micron-scale 3D printing brings the complexities possible with 3D printing down to a scale often measured by the width of a hair or how much smaller than an ant a finished product can be. Microlight3D has been developing some intriguing technologies for its take on high-resolution, micro-scale 3D printing.

Today’s Statue of Liberty — more on her soon — celebrates not only international ties and government changeover, but new introductions from Microlight3D. The company describes its technology:

“Microlight3D’s technique is based on two-photon polymerization, consisting of a green pulsed laser (operating at 532 nanometers wavelength), which combined with ultra-precise moving stages creates 3D-objects in a photoresist with sub-micron resolution. A simple solvent bath removes the unpolymerized resin.”

The new introduction to their capabilities is called Long-range Z. This feature “breaks through the height limitation of micron-sized structures, while maintaining micrometric resolution.” It is designed to enable users to 3D print tiny objects as tall as 10mm — notably taller than the previous 0.3mm limitation.

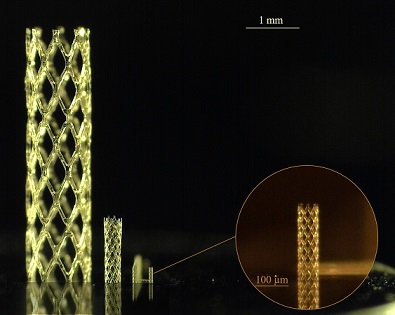

This additional height capability opens up more potential for micro-sized builds. Microlight3D notes that the development is in response to research and industrial development demand. Now several-millimeter-tall objects can be made in one print. Think tiny developments in mechanical micro-parts, meta-materials, and medical devices.

“Users can produce mechanical micro-parts and meta-materials enabling new features in terms of rigidity, elasticity, lightness and reaction to stress. They include medical devices, such as stents and micro-needles for transdermal injection, as well as micro-optics used as lenses on optical fibers, connectors and innovative micro-endoscopes, among others,” the company explains.

Microlight3D has also developed the ability to precisely 3D print on a variety of compatible substrates. 3D printing on metallic or opaque substrates opens up new possibilities for tiny prints. They can 3D print “on the tip of optical fibers for micro-optics applications,” as one example the company suggests.

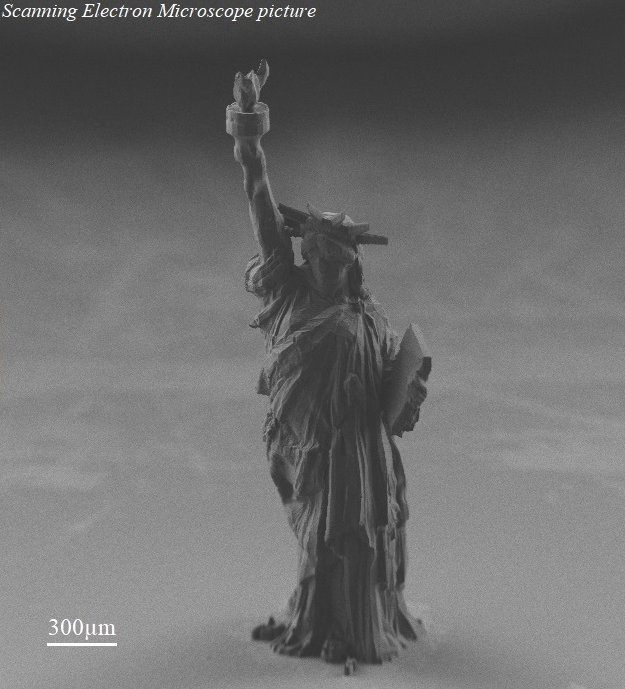

3D Printed Statue of Liberty

To demonstrate the Long-range Z ability, and to show off their newest material, we have the bitty Lady Liberty.

She was 3D printed directly on top of the word “Liberty” on a US penny, and measures 1.8mm tall and 0.6mm wide. She is made of OrmoGreen, a polymer material doped with silica nanoparticles.

“Users will also be able to make alignments on a pre-existing pattern and print exactly where they want. We had great fun positioning the replica of the statue on the word ‘Liberty’ on a United States one-cent coin. Researchers and industrial developers are looking to work on metallic or silicon wafers. Our enhanced 3D microprinting system, compatible with a wide range of materials and substrates, will allow them to micro-fabricate structures they couldn’t before; they will marvel at the ability of our µFAB-3D-Advanced 3D-microprinter to align the laser and print on the tip of optical fibers for micro-optics applications,” said Microlight3D Co-Founder Philippe Paliard.

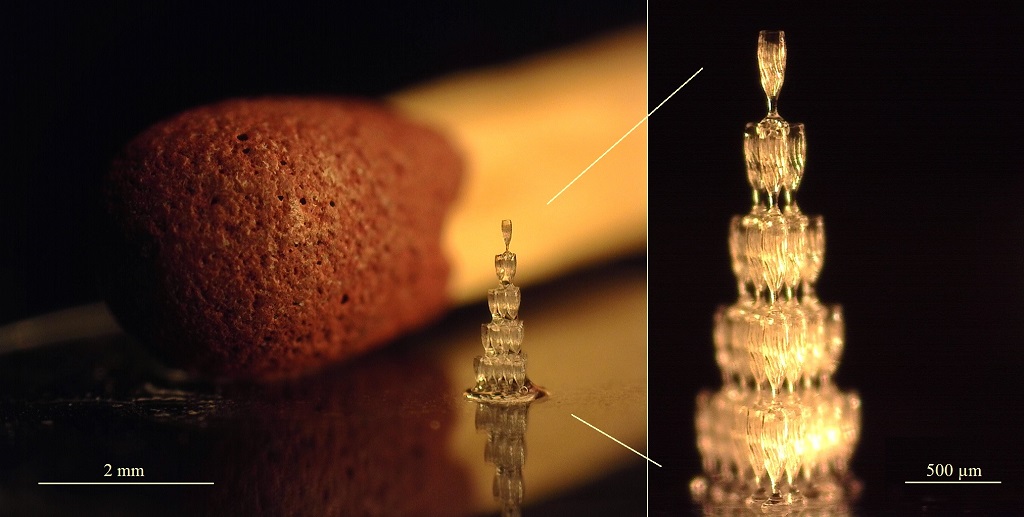

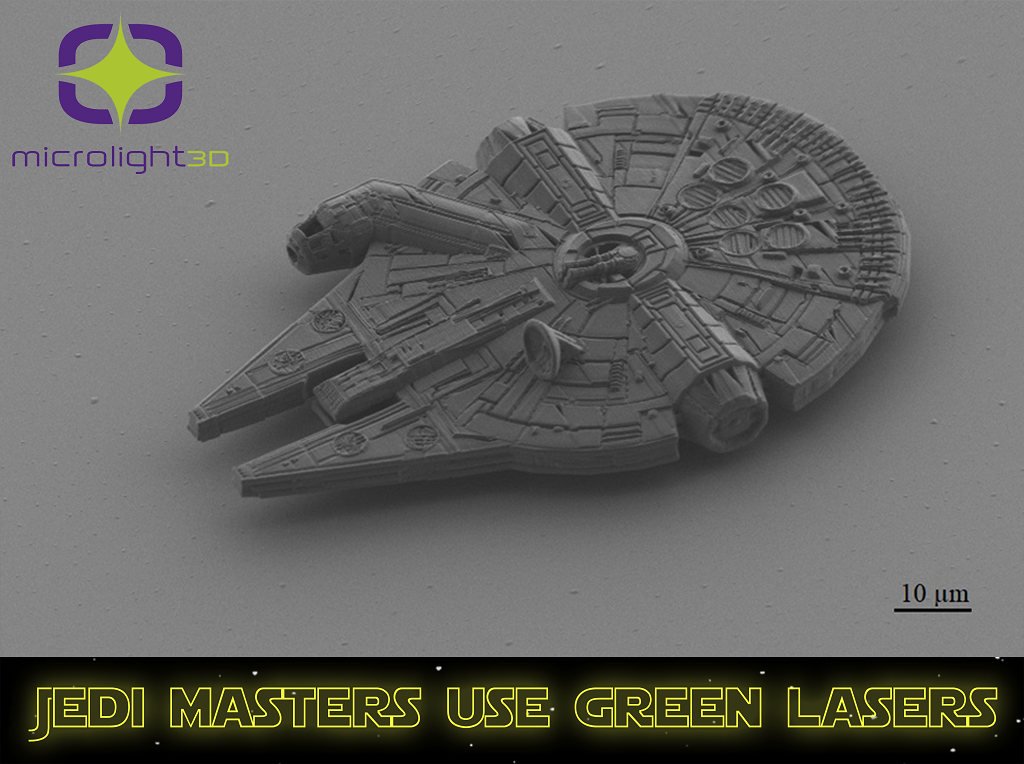

Microlight3D has a history of commemorating celebrations with wee 3D prints — today the inauguration of President Joe Biden and Vice President Kamala Harris; for New Year’s, a delightfully tiny champagne flute tower; for the release of the second season of The Mandelorian, a green laser-celebrating Millennium Falcon. Because not only researchers and medical developers use green lasers; so do Jedi masters. This is the way.

Happy New Year! Champagne flute tower with a matchstick.

Via Microlight3D