Charles R. Goulding and Preeti Sulibhavi look at recent developments in use of 3D print technology for repair activities.

On October 13th, 2022, the Additive Manufacturing (AM) Coalition presented a webinar titled, “The Use of Additive Manufacturing for Repair.” We attended this webinar and found it highlighted some key points that anyone interested in advancing AM for repair should consider.

The webinar featured the following panelists:

- Dave Ramahi, President & CEO of Optomec Inc.

- Dr. Jason Jones, Co-Founder & CEO of Hybrid Manufacturing Technologies

- Mr. Dave Abbott, Chair of SAE International AMS-AM Repair Subcommittee on Additive Repair for Aerospace, and Senior Staff Engineer of General Electric Aviation

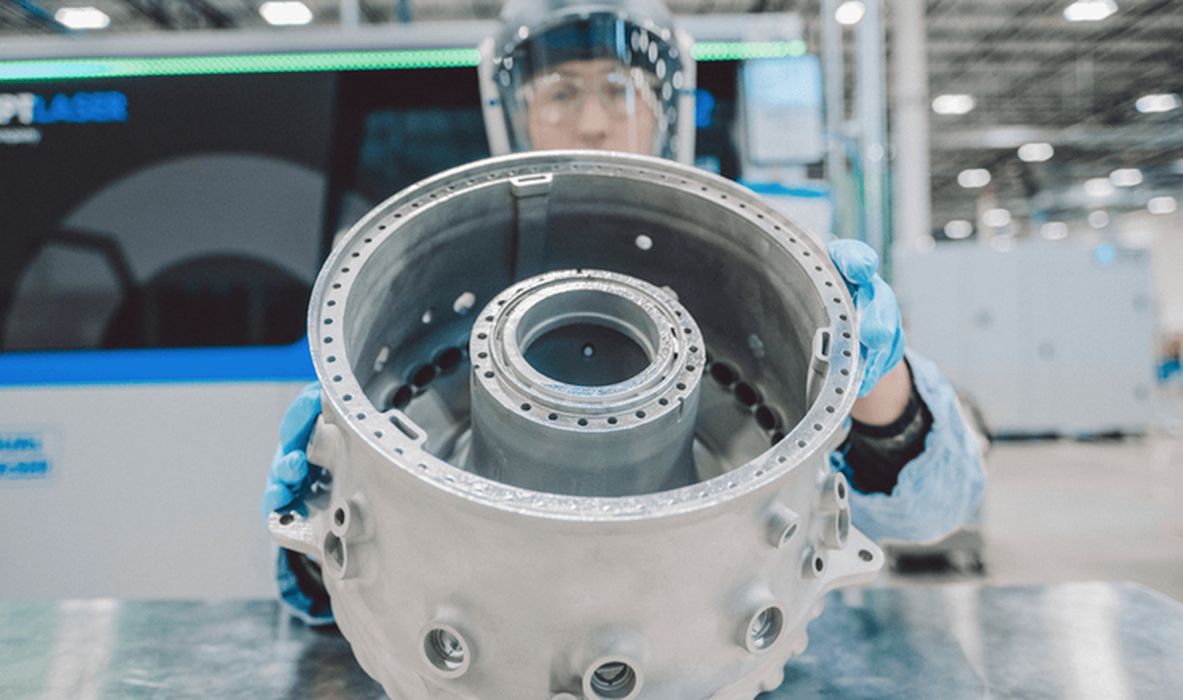

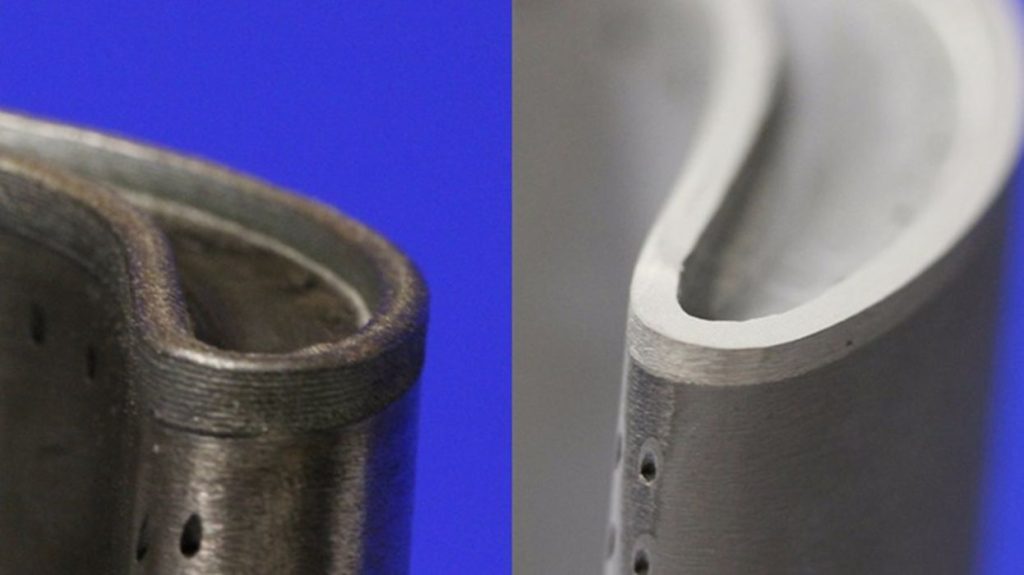

The webinar covered a host of applications of AM to repair in various industries, such as the food and beverage industry, but particularly focused on aerospace and defense. Turbomachinery was emphasized and the use of hybrid AM systems in repairing these parts is becoming increasingly common.

3D Printing & Repair

3D printing can be used to repair equipment and machinery used in production. Using 3D printing for repair can decrease downtime, improve production efficiency, and reduce costs for companies. The only party in this transaction that would like to contradict these findings are replacement part vendors.

Optomec Inc and 3D Printing

Optomec Inc specializes in 3D printed metals, primarily for next-generation medical devices and wearables. Optomec offers a range of solutions for metal processing and hybrid manufacturing. For example, the LENS 860 Machine Tool Systems offer larger build volumes and increased power capabilities for AM and hybrid manufacturing metal processing, and is ideal for repairing mid to large-size parts with higher quality. Optomec customers include GE and the University of Pennsylvania (UPENN).

Hybrid Manufacturing Technologies

Hybrid Manufacturing Technologies is a firm that specializes in laser-based hybrid CNC systems. Its proprietary technology is called RECLAIM (Remanufacturing of high-value products using a Combined Laser cladding Inspection and Machining System). This system eases the transition from CNC machining technology, currently in place in many facilities, to AM-based production.

GE and 3D Printing

GE is using 3D printing to repair parts in production for clients such as Boeing. GE Aviation’s AM repair subcommittee was established in 2019 and is now working to create a framework for standards for AM repair applications. Mostly the team has been using 3D printing materials such as metals and polymers. But they are researching how to use ceramics going forward as well.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The AM Coalition’s webinar was insightful as each panelist provided a myriad of ways 3D printing is providing solutions to repair and replacement part issues for many manufacturers. Given the current supply chain constraints, 3D printing is looking even more promising for repair.