Two companies announced developments in bioprinting technology.

Bioprinting is one form of 3D printing, but dedicated to the production of 3D objects made from living cells or other biomatter. It’s current a niche area, but in time it could develop into a widely used technology seen in labs and healthcare facilities.

This week saw announcements from Fluicell and Brinter.

Brinter Visco Bio

We’ve previously written about Brinter, which is a Finnish company developing a bioprinter they’ve named “Brinter”.

They haven’t announced a new bioprinter, but instead have released a new printhead, the Visco Bio, which can be used in existing Brinters.

The major feature of the Visco Bio is that it offers “zero dead volume”. You might be wondering what that means, as it is not a term used in conventional 3D printing, even though it definitely occurs.

Zero Dead Volume is the amount of material that is wasted during a print job, typically caught in the printhead and unable to be extruded. In other words, there is usually a minimum amount of waste to occur with bioprinting printheads, which are syringe-like mechanisms pushing bio material from a cartridge.

There’s certainly polymer waste in FFF 3D printers of this type, but it is of little consequence because the material is inexpensive. On the other hand, biomaterials can be quite expensive, as they are often very specific living cells that had to be grown separately in lab environments.

The ability to reduce the waste of this expensive biomaterial could be quite important for many operations. This could reduce the cost of materials, but more importantly can provide more capacity for print jobs, which normally can use only a single cartridge of material.

Brinter CEO Tomi Kalpio said:

“The release of this print head means that basic requirements towards Good Manufacturing Practices (GMP) are met, for example, due to no cross-contamination with the use of a single cartridge per material, used together with the disinfecting blue light module we published in December. Likewise, researchers, pharma industry, and universities benefit from the repeatability of printing results being increased due to continuous and precise printing processes.”

Fluicell Biopixlar AER

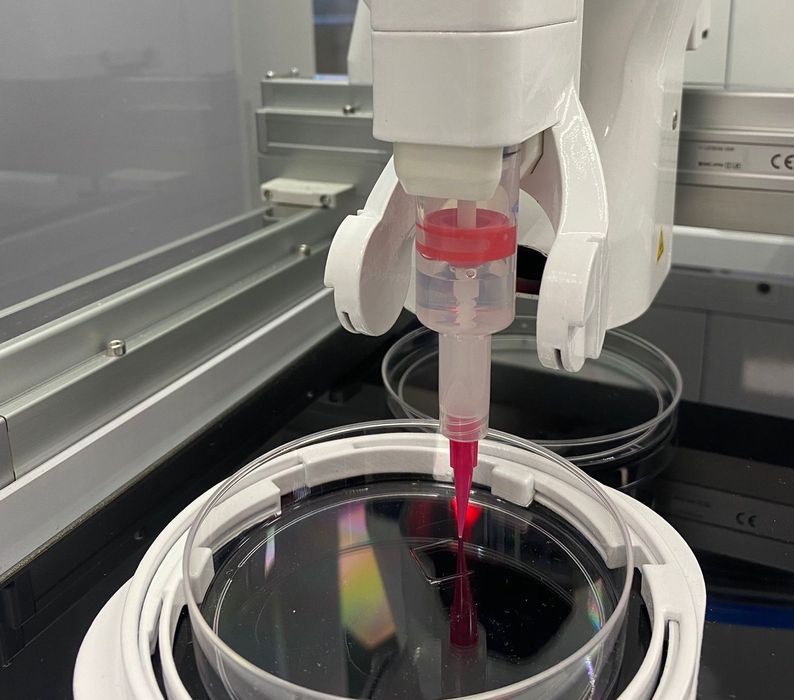

Fluicell announced a new compact bioprinter, the Biopixlar AER.

The interesting feature of the Biopixlar AER is that its microfluidic printhead has the capability to deposit single living cells during a print job. This means that it could literally build up a section of living tissue cell by cell. By combining different types of cells, it might be possible to build all manner of tissue types.

Before you get too excited here, this does not mean the Biopixlar AER can 3D print human organs for transplant. That’s well beyond the current capabilities, most importantly because cells require constant nutrients. Without building a vascular system, bioprints are typically very thin to allow nutrients to soak through.

There’s another interesting feature of the Biopixlar AER: its very compact design is sufficiently small to allow the device to be used inside standard biosafety cabinets that are commonly used in the industry. These would permit many more applications to be attempted with the Biopixlar AER.

Now, it’s up to researchers to determine how to apply this interesting new device.