Charles R. Goulding and Preeti Sulibhavi look at how 3D printing technology has affected military supply chains.

The above 2017 picture shows Abrams tanks in Poland. With Russia at its doorsteps, military readiness in Poland and other eastern European countries is now of critical concern. Russia defeated both Napoleon and Hitler because of inadequate supply chains and the Russian winter. In the five-plus years since 2017, the U.S. military has made substantial investments in 3D printing to improve supply chain resilience and overall performance.

In 2021, we covered ExOne’s $1.6 million Department of Defense (DoD) contract for portable 3D printing. This contract will presumably meet the United States’ new, more rigid Buy American goals. We discussed both the Federal and Pennsylvania R&D Tax Credits later in the referenced article.

The portable factory is within a shipping container enabling it to be moved and operated efficiently in the field. Within the 40-foot-long container is a 3D Scanning & Prep Station, Ruggedized Metal & Ceramic Binder Jet 3D Printer, Curing Oven, Fiber-reinforced Plastic 3D Printer, and a Compression Molding Station.

The idea of 3D printing in a portable container that can be deployed as needed has been taking off lately, especially among military applications. One large-format 3D printer is also made in a shipping container. The ExOne solution offers an interesting binder jetting angle to the idea.

In October of 2020, Desktop Metal received a three-year, U.S. Army Contracting Command $2.45 million award intended to fund the development of cost-effective, high-volume Additive Manufacturing (AM) process capable of manufacturing the novel Co-free hard metals into complex, net, or near-net shaped parts without the use of any tooling.

In February of last year, the DoD released a comprehensive manufacturing strategy that aims to establish a united vision for utilizing 3D printing in the U.S. defense program. This was unprecedented. The strategy outlines the key ways additive manufacturing can support US defense activities by modernizing and improving performance.

3D printing is helping to substantially increase material readiness for quick prototyping and production of end-use parts, thereby reducing the risk of obsolete hardware.

We have also covered Australia’s Blackhawk helicopter purchase in January of this year and how 3D printing is aligned with helicopter replacement parts and out-of-stock parts as well. It is referred to as the digital twin process.

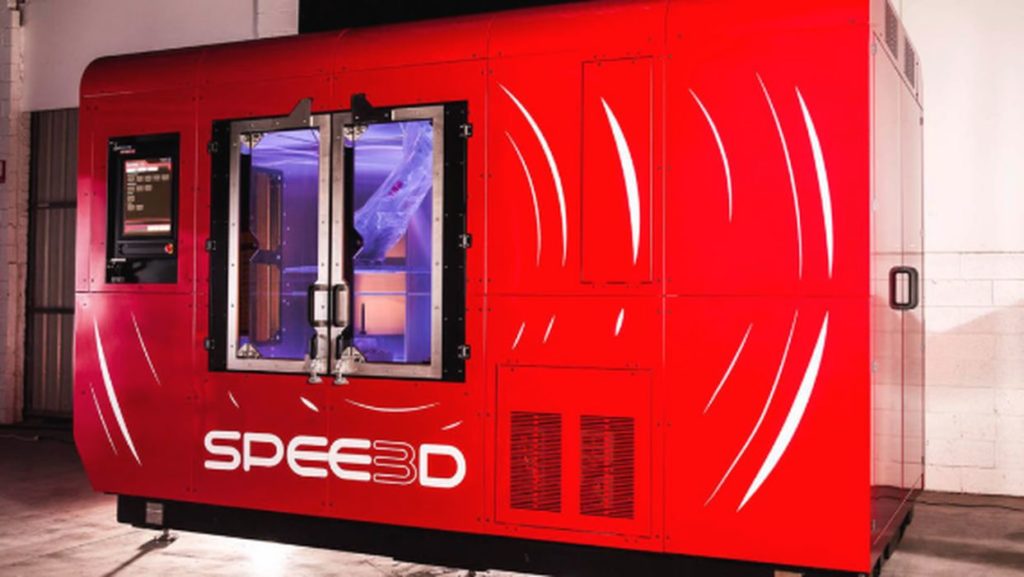

WarpSPEE3D

There is another very relevant application that 3D printing has to the armed forces. SPEE3D’s WarpSPEE3D printer, a high-speed 3D printer capable of building multiple components, has been used in field tests in the Australian army in recent years.

In 2020, the field trials demonstrated that SPEE3D’s WarpSPEE3D printer was capable of operating even in remote Australian bushland. In 2021 field trials, the Australian Army successfully demonstrated it is possible to 3D print, certify, validate and replace armored vehicle parts in real-time. This is an extensive effort.

During 2022, the U.S. Army’s Rock Island Arsenal will be set to receive its second SPEE3D 3D Printer and can leverage the capabilities of this advanced technology to tackle supply chain challenges and part replacement issues.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

With the eye-opening invasion of Ukraine, the U.S. Army is focused on troop deployment and readiness. 3D printing is now an integral part of the military supply chain.