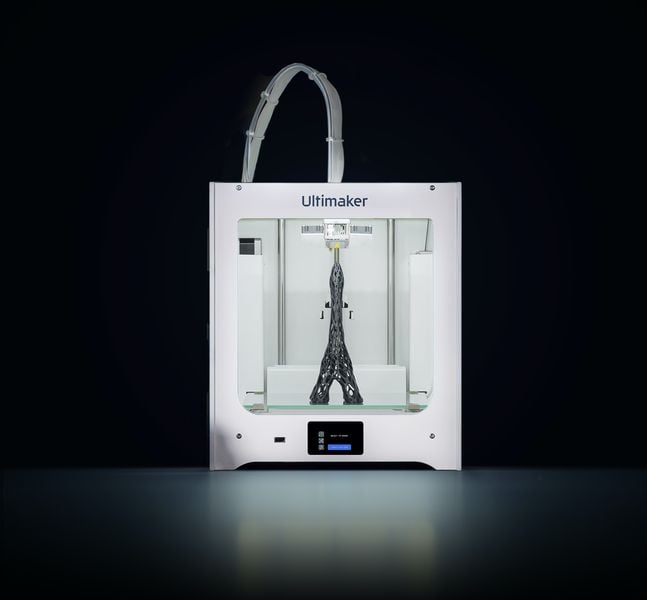

Ultimaker announced a new entry-level 3D printer, the Ultimaker 2+ Connect.

The new device effectively replaces the long-standing and wildly popular Ultimaker 2+ with its new convenience and usability features.

Ultimaker 2+ Connect

The Ultimaker 2+ Connect is visibly similar to the Ultimaker 2+, but there’s actually quite a few differences. One major difference is the control panel, which you can see here:

The predecessor’s control panel was a much more primitive affair with a limited-resolution screen and a single control wheel. In a world where even low-cost 3D printers now feature color touchscreens, it was time for Ultimaker to do the same on their entry-level device. The new machine has a 2.4-inch touchscreen that should be much easier to use.

Inside the box, Ultimaker has apparently stiffened the build platform, and that should translate into more accurate builds. Less wobble is always welcomed on any 3D printer.

Another usability feature is the addition of an “ergonomic feed lever”. This should make the loading of 3D printer filament a bit easier and perhaps even more reliable. Again, I’ve been seeing some innovative approaches on low-cost equipment and it appears that Ultimaker is catching up here.

The machine is capable of participating in Ultimaker’s cloud to allow for remote operation through WiFi.

A standard 0.4mm nozzle is shipped, but it’s possible to quickly swap it for either a 0.25mm nozzle for detailed 3D prints, or a fat 0.8mm nozzle for rapid larger-sized 3D prints.

One interesting claim from Ultimaker is focused on machine upkeep. They say:

“The clean and updated design keeps scheduled maintenance to just 4 hours per year, ensuring a high uptime – with no special tools required for maintenance tasks.”

This is very interesting, as machine reliability is quite important, particularly where there are multiple units installed. That’s likely the case for the market Ultimaker is targeting with this box: educational use, where arrays of Ultimakers would be put to work on student projects.

In such environments even a slight increase in maintenance would be multiplied by the number of devices. By reducing the maintenance to only 4 hours, it would seem that a single tech could maintain over 600 devices! I’m not sure that’s really possible, but I’m certain institutions would welcome the change.

Another feature for educators is the bundling of e-learning courses with Ultimaker’s 3D Printing Academy. This again should greatly assist in setting up the equipment and likely take a load off of Ultimaker themselves as the self-service model here would be quite efficient for them.

Ultimaker CEO Jos Burger said:

“True progress happens when reliable technology is accessible to everyone, everywhere. By seriously upgrading our most popular single extrusion 3D printer while maintaining affordable pricing, educators and small enterprises can keep getting their hands-on powerful entry-level 3D printers that simply work, day and night.”

And there’s more: Ultimaker is also offering an optional accessory borrowed from their more expensive equipment — the Air Manager. We first saw this on the Ultimaker S5 Bundle last year.

The Air Manager fits on top of the otherwise-open build chamber to lock in air, and the front door is replaced with something with more sealing power. This allows the Air Manager to pull air from the build chamber and filter it before exhausting. The idea here is that emissions and nanoparticles can be captured and not let loose in the printer area.

That’s good for safety, but it’s also important for 3D printing, as the Air Manager will also trap heat in the chamber, thus reducing the thermal gradient and reducing the warp on certain types of 3D print materials.

It’s been a while since Ultimaker upgraded this product category, as they’ve been focused on larger-scale business use markets for quite a while. I’m sure the new machine is going to be welcomed by many happy Ultimaker 2 and 2+ clients that are looking for an upgrade to aging equipment.

The Ultimaker 2+ Connect is available now from resellers and is priced at €2050 (US$2499), and the optional Air Manager is priced at €350 (US$450).

Via Ultimaker