Sintavia published an excellent document describing the condensate problem at many metal 3D print operations.

Sintavia is a well-regarded Florida-based AM manufacturing service that offers design and production services, as well as laboratory testing and quality control. As part of their activities, they operate 28 metal LPBF 3D printers for metal production.

3D Printer Condensate

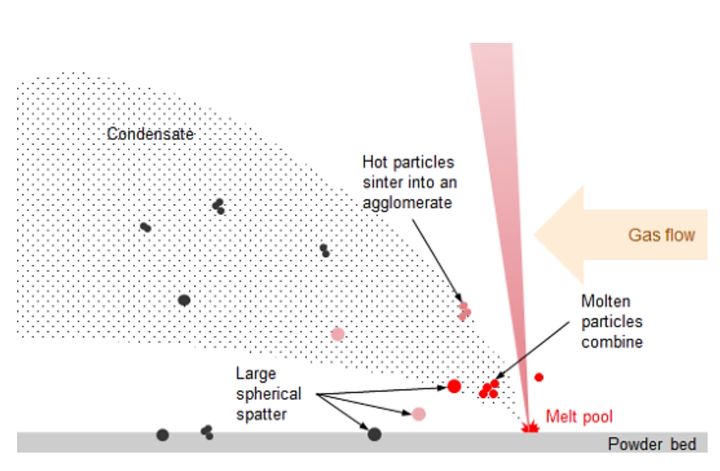

Metal LPBF 3D printers can suffer from the condensate problem. During 3D printing the atmosphere in the build chamber is replaced with an inert gas to prevent explosions (because some powdered metals are explosive when combined with oxygen from the air and heat from the lasers).

This inert gas must be recycled, as it’s a valuable consumable for metal 3D printing operations. It can be filtered during and after 3D printing, but some of the metals used during printing evaporate into the gas and condense out. You end up with a quantity of condensate.

Sometimes this condensate is flammable or toxic and thus it must be disposed of in a proper manner. Unfortunately, some metal 3D printer operators don’t bother to do so and have growing piles of condensate in buckets in a back room. That’s a problem that some unfortunate manager will eventually discover.

That’s not the correct way to handle condensate, but what is the right way?

Sintavia Condensate Procedures

Sintavia published a white paper describing their thoughts on the condensate problem in great detail. The paper was written by was written by Sintavia’s Quality & EHS Engineer, Ashley Wallace, in collaboration with the Additive Manufacturer Green Trade Association (AMGTA) and Triumvirate Environmental.

Sintavia explains the regulations behind their process, which are from the US EPA. Readers in other regions should have similar regulations from their authorities. Here’s their description of condensate:

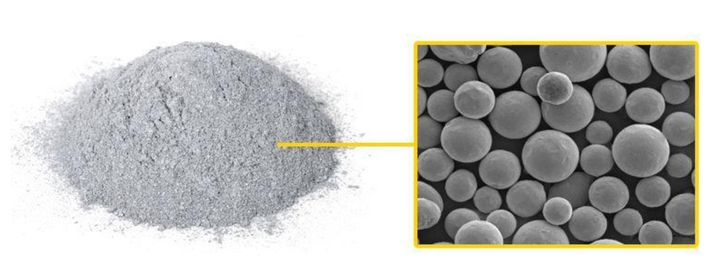

“Condensate is described as a vapor plume resulting from evaporation of a metal alloy during the AM PBF process. The vapor is subjected to continuous gas flow within the build chamber which can rapidly solidify the condensate into particles. These condensate particles are made up of numerous metals, usually with hazardous and combustible elements. Dry condensate is carried away using the machine’s inert gas flow, through a filter system, then deposited into a bin for removal. Wet condensate, which includes spatter, is suctioned out of the build chamber itself using a water based wet separator vacuum.“

The process for disposal is arduous, but must be done. It involves first having an evaluation of the condensate by a third-party lab to officially determine the types of materials and their hazards in the condensate. Remember, the 3D printer might have been used for a number of different materials or alloys, so it can be unpredictable what’s in the condensate.

What does Sintavia do with their condensate? They explain:

“Currently at Sintavia, condensate is handled and disposed of per standards set forth by the EPA, Florida Department of Environmental Protection (FDEP), and Florida Department of Transportation (FDOT). These standards are adhered to at the highest level when working with condensate. While using a wet separator vacuum, condensate is recommended to be neutralized by water or oil with organic additives. For dry condensate within the machine, argon gas is utilized to prevent any oxidation/reaction of the powder during exposure. From the printer, dry condensate is then transferred into an airtight particle bin promptly filled with sand and silicone oil as the neutralizing agents.”

If you’re a metal 3D printer operator, you’re likely quite aware of the condensate issue. If not, you’d best have a read through this white paper.

Right away.

Via AMGTA (PDF)