voxeljet announced a new on demand 3D print service able to produce flexible parts in TPU.

voxeljet is a German company that has been producing large-scale 3D printers for many years. In fact, their VX4000 has a massive build volume of 4000 x 2000 x 1000 mm. It’s so large you really have to refer to its volume in meters, not millimeters.

The company’s original products were designed to produce molds for foundries in both sand and polymer for industrial casting of large parts. Since then they’ve developed a number of innovations to broaden their portfolio of capabilities. HSS, for example, is a polymer-based process that uses infrared light to quickly fuse layers of polymers like PA12.

The HSS process was eventually tuned a few years ago to enable the use of flexible materials, like TPU. Incredibly, they were able to achieve minimum wall sizes of only 0.15mm in this process.

Now the company is offering this capability as an on demand service. They explain how it works:

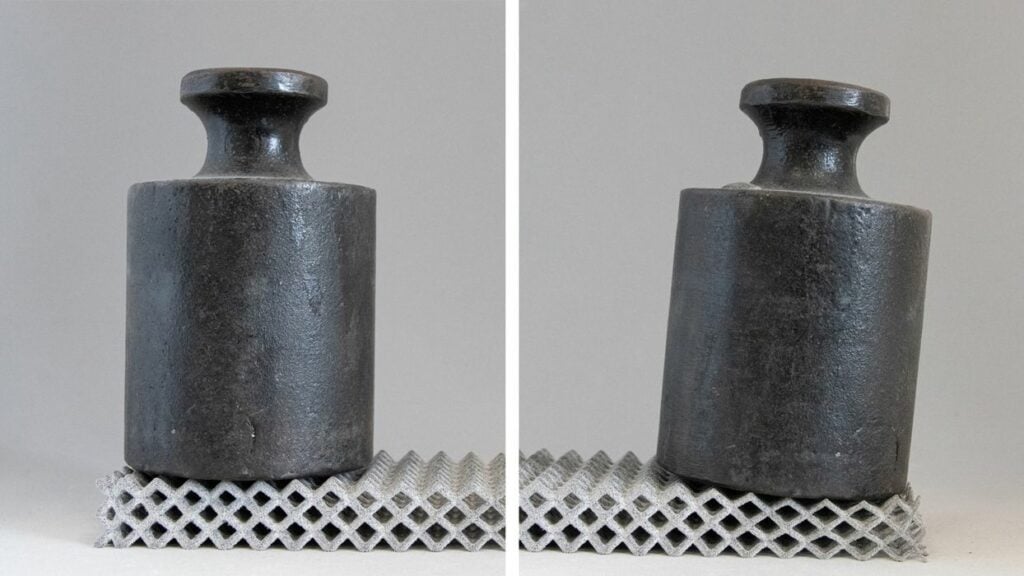

“TPU can be very soft and elastic or very hard and persistent. These properties can be specifically influenced in all three dimensions using HSS technology. In High Speed Sintering, a fine layer of polymer powder is applied onto a heated build platform and the areas where the part is to be built are then inked with a heat-absorbing ink. Infrared light is used to fuse the printed areas of the polymer powder, leaving unprinted material loose. Layer by layer, the polymer is applied, printed, and irradiated until the build-up of the full jobbox and the parts within it, is complete. How soft or solid the part is depending on the volume of infrared-absorbing ink introduced. The more heavily a build area is inked, the stronger the part. By using industrial inkjet print heads, it is possible to print correspondingly different gray levels within a layer and thus realize different product properties per layer. In addition to this grayscale printing, the strength of a component can also be influenced by its geometry. Lattice structures with different wall thicknesses are used to print geometries that can be adapted to individual load profiles in order to save additional material.”

Why offer this as an on demand service? I think there are multiple drivers here.

- There is increasing interest by product manufacturers in using complex lattices combined with flexible materials

- Many of these manufacturers are new to 3D printing and would be quite unlikely to purchase a massive voxeljet device as their first venture into the technology

- An on demand TPU service could enable such customers to use the tech without huge immediate expense and large learning curves

- voxeljet’s equipment is quite large, and is best used when jammed full of prints, running 24/7; a print service could create that type of workload

- The large build volumes would easily allow service customers to scale up or down their requests

- voxeljet’s stock price has been trending downward since February 2021, and management could be looking for additional revenue and growth opportunities

The new service seems to hit quite a few important factors, so it makes sense for both voxeljet and their clients.

Via voxeljet