Wemake answered our questions regarding their prototype belt ejection system for desktop 3D printers.

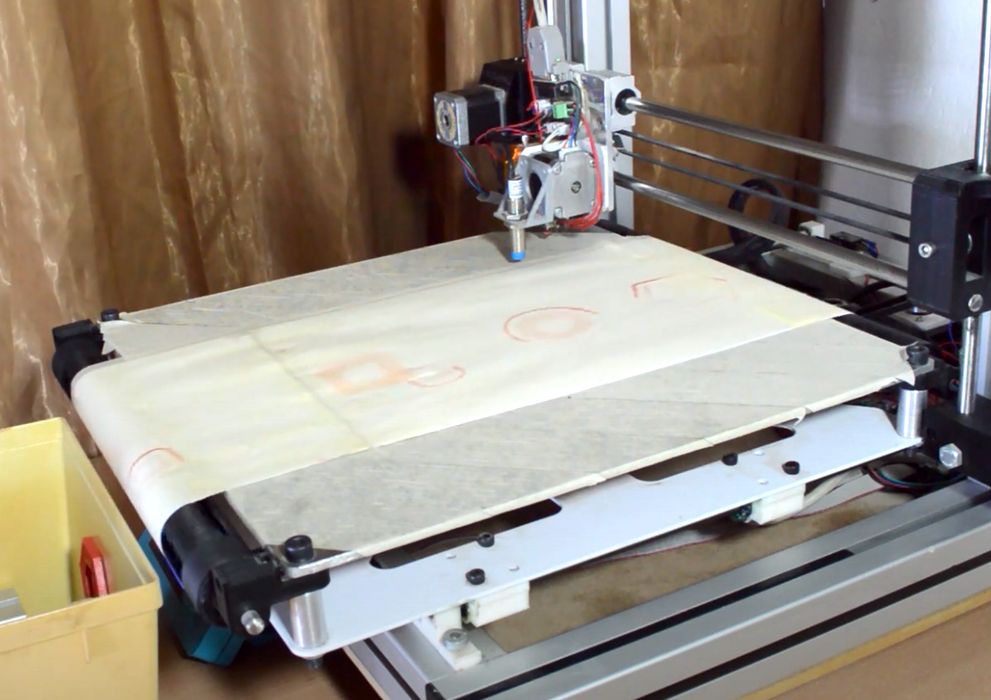

Their system essentially wraps the print plate with a moving belt. The idea is that the print takes place on the stationary belt as normal, but then is ejected by rolling the belt one cycle at print completion. The print falls off as the belt curls around, and this leaves the print surface clear for a subsequent print job.

I spoke with Abdelmagid Mathlouthi, the Founder and CEO of Wemake, a small local manufacturer of 3D printers and parts service based in Manzil Bu Zalafah, in Tunisia.

Fabbaloo: How did this idea come to be?

Abdelmagid Mathlouthi: It all started as a graduation project back in 2019 and it was just a proof of concept system to show the advantages and uses of such system compared to ordinary 3D printers and compared to already existing belt printers that keeps the belt moving all the time.

Fabbaloo: Is there an intention to sell this concept as a product in the future?

Abdelmagid Mathlouthi: First, this is an experimental version. It will be for sale in the upcoming weeks/months. Sourcing equipment and components here, (Tunisia) is extremely hard, as we do not have access to online stores due to the lack of online payment processors. We plan to sell this product in Tunisia first, and we already have some demand from 3D printing businesses and we are looking forward to attract some industrial users, which are so few. The technology of 3D printing is still not popular.

Fabbaloo: What is your target price for the product?

Abdelmagid Mathlouthi: For pricing, we are thinking of keeping it under US$100. We are in the process of choosing the correct belt. As I said, importation is nearly impossible so we are adapting what we have in the local market. We have been selling normal FDM desktop 3D printers since August 2020, and we managed to sell 20 units to associations, FabLabs, university clubs, architecture firms and personal users.

Fabbaloo: It appears in your video that the system is installed on one of your own 3D printer models. Will it be offered as an upgrade kit for other popular desktop 3D printers?

Abdelmagid Mathlouthi: We will provide the system as an upgrade kit for our own 3D printers as well as for some other popular brands. For now, we plan on adapting of our system to Prusa and Creality 3D printers.

Fabbaloo: What is the belt made from? How durable is it? Can it be replaced? Does the belt warp over time, causing z-gap issues?

Abdelmagid Mathlouthi: In the published video, we just used ordinary A4 paper covered with yellow paint tape. Yellow paint tape is cheap and effective print surface for mainly PLA. We think of using stainless steel belts or wear resistant nylon belt used in industry. Our system is easy to install and remove and requires little modification.

It is now compatible with the Marlin firmware as we integrated the ejection sequence as an independent M code command. To adapt the GCODE files, we developed software called the “Stitcher”, which stitches GCODE files together and adds the eject command in between them, then the Marlin firmware calls the eject command and the automation process begins.

For the hardware part, it only needs seven wires: two for the supply power to the motor, 3 for the sensor that goes in the board, and two for digital signal to command the DC motor driver (H Bridge). The belt is easily replaceable by only loosening four screws.

For the warping issue, most if not all belt printing solutions use the belt as the build surface and the moving Y-axis at the same time. This reciprocating movement will cause the belt to wear fast over time as it is already under constant traction for tensioning. Our solution keeps the belt’s movement stable as in any ordinary i3 3D printer and only engages the belt for the ejection that is 15 seconds or less of working time compared to hours of 3D printing. This minimum effort for the belt keeps it intact for a longer period compared to other solutions on the market, and avoids warping.

Fabbaloo: Finally, a reader was concerned that your design likely violates MakerBot’s patent on their “automated build platform”. This is why most other systems have a moving belt. Do you have any thoughts on this issue?

Abdelmagid Mathlouthi: There is a section 14 in the patent that claims the ejection with a conveyor belt after the part was fabricated but as we can see, the tilted 45° 3D printers such as the black belt and the CR-30 use the same claim. Some others say that the conveyor belt system is widely used and no one can claim it unless it is used in a very specified configuration. The MakerBot patent is about a 3D printer that has an automated build platform. Our solution is about a “kit” that ejects parts after they are 3D printed. Putting this aside, the patent is only valid in the US so we can simply not sell it there.