New research has shed some light on the intrinsic resolution of photopolymer 3D printing.

In any kind of resin 3D printing, energy is applied to a liquid photopolymer, which then dutifully solidifies. By selectively engaging the energy at different points on a fluid resin surface, a solid layer can be produced.

Often the “best” resolution is sought for such 3D prints, as they typically compete against injection molded equivalents that have by definition totally smooth surfaces. In other cases high resolution is required to produce tiny structures, and recently these have become increasingly complex due to the application of generative design techniques.

But what, exactly, is the maximum resolution of resin 3D printing?

Some would say it is simply the size of the laser dot in SLA systems, or the size of the pixel in DLP/LCD systems. That’s mostly true, but becomes less clear as you shrink those down.

It turns out that there is always a bit of slop beyond the formal boundary of the laser dot. This happens because the energy seeps through the resin and solidifies a little bit of the surrounding area.

You could limit this effect by shortening the laser strike or shrinking the laser dot, but you actually need to provide a minimum amount of energy to an area for it to polymerize. If you have one, you have a bit of the other.

Researchers at NIST attempted to measure this effect in a paper entitled “Voxel-Scale Conversion Mapping Informs Intrinsic Resolution in Stereolithographic Additive Manufacturing”, and it seems they’ve made some interesting discoveries.

The problem is that parts don’t exactly come out as intended. The researchers explain the issue:

“These parts exhibit intrinsic mechanical heterogeneity and poor dimensional accuracy that is not explained by simple critical energy dose models that pervade the field. Moreover, resolution requirements for new applications in metamaterials and bioprinting (e.g., human cell scale <10 μm) push the limits of what is currently achievable in scalable single-photon processes.”

They developed a new scanning probe to observe polymerization in process using a cantilever mechanism to detect vibration resonance with an atomic force microscope. The theory is that vibrations change as polymerization occurs.

The action that takes place during polymerization is far more complex than I had imagined.

They say:

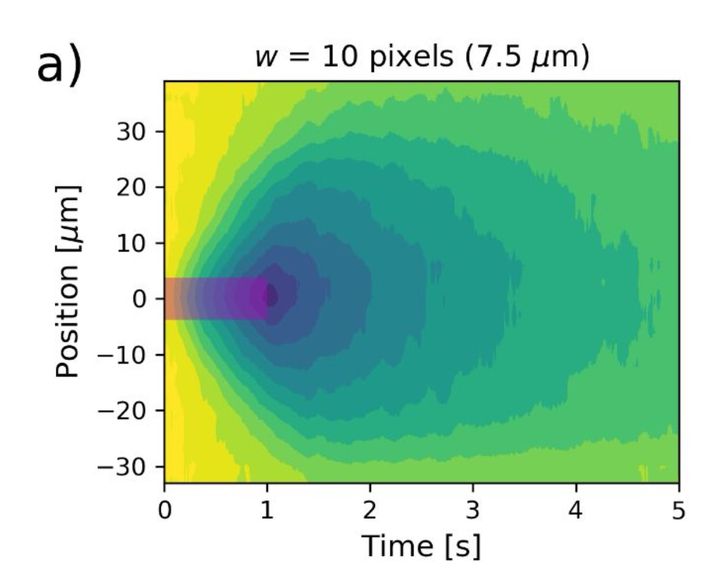

“The drag force experienced during cantilever oscillations can be correlated to the viscosity and extent of reaction. Fluid dynamics simulations show micrometer-scale measurement localization, and the resonance-based measurement allows submillisecond temporal resolution. In a thiolene resin exposed to patterned light, oligomer diffusion length scales are significant compared to the size of printed structures. Consequently, part resolution is dictated by the competition between polymerization and diffusion.”

In other words, the act of polymerization seems to cause some action that creates the over-polymerization.

What did they find? They explain their results:

“We investigate the effects of light intensity and photopattern size on the reaction conversion profile and find that the radical polymerization mechanism limits the usefulness of increased light intensity to enhance feature resolution by decreasing conversion at a constant dose. We also detect polymeric species diffusion tens of micrometers away from illuminated pixels within seconds, which affects the final shape of printed test structures.”

Somehow this is not surprising, but here the researchers were able to directly measure these effects.

At this stage the technique seems only used for this experiment, but I can imagine it could be used in the future to help design ultra-accurate 3D printing resins. Through an iterative process a resin producer could directly measure these effects in an effort to identify resins that minimize over-polymerization. Of course, this would certainly be constrained to measurements of a specific combination of resin and light.

If such an approach were used, we might see new families of photopolymer resins appear on the market that could provide print accuracies and resolutions above that of today.

Back to the original question, what is the maximum resolution. Clearly, the answer is, “it depends”.

Via ACS