I had the opportunity to catch up with Eugene Suyu, Founder and CEO of Tinkerine.

Vancouver-based Tinkerine (pronounced “Tinker-een”) is one of the older 3D print companies, having been formed close to a decade ago. But in recent years we haven’t seen much from them. It turns out there is a reason for this.

Tinkerine History

Many of their contemporaries have since disappeared, having been swallowed up in the consumer 3D printing crash. But Tinkerine took a strategic path way back then, and still do today.

The last time I saw the company at a trade show many years ago they had taken the unusual step of focusing on a specific application area: education. That was a highly unusual move at the time, because most of the 3D printer manufacturers of the day sought to become large in the consumer space and therefore positioned their equipment as general purpose.

Of course these days we know that’s a losing strategy; buyers must get value from their purchase, and that comes by using the machine for a known and profitable purpose.

Somehow Tinkerine saw this well in advance of other companies, and shifted their focus towards education.

While they made 3D printers, and still do, the Ditto line is a side story for the company. Initially they produced well-thought-out educational materials to accompany their equipment, but eventually realized their core purpose was in fact the education on 3D printing technology.

Founder Eugene Suyu explained:

“Building 3D printers was not a business for them — it’s a race to the bottom. Instead we’re focusing on skills and supporting that with content.”

I saw some of their material years ago and was quite impressed. For example, their classroom projects always involved simple 3D models that could usually complete 3D printing during a class, as opposed to running overnight.

As a result of their strategy switch, they effectively disappeared from the usual 3D print trade shows. That’s why we haven’t seen them for some time: they have been working the education shows instead, where they can find plenty of prospects.

Tinkerine Today

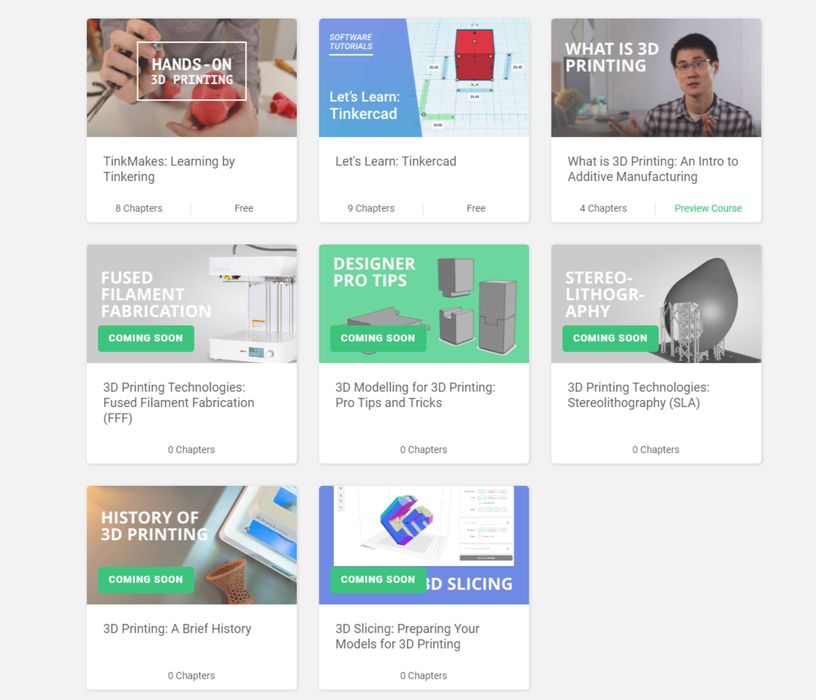

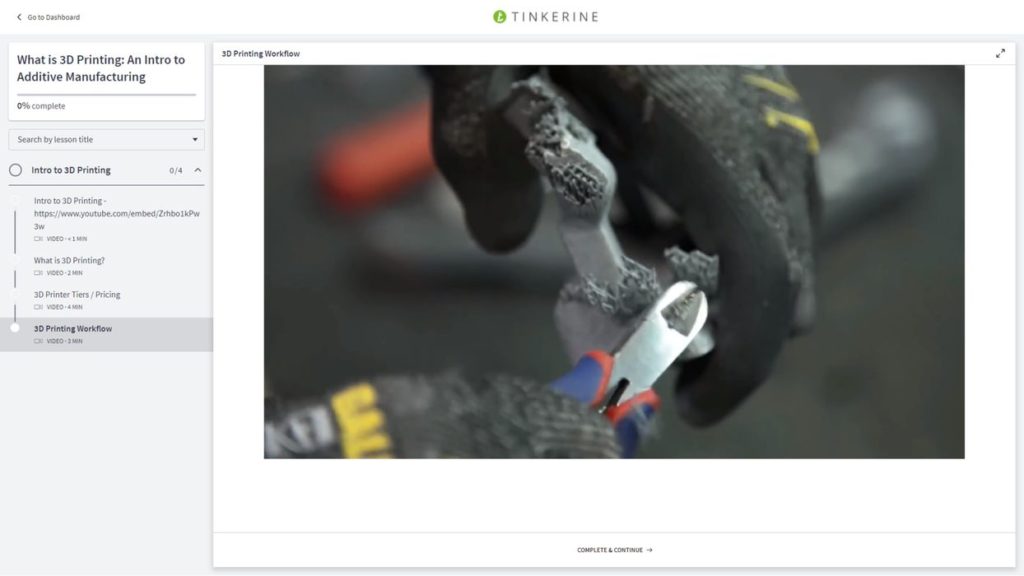

Today they’re really product-agnostic, and have been providing comprehensive educational material for 3D print technologies to students and teachers. Suyu said:

“We produce education about the technology, and give students the best chance to get the right knowledge and make the best decisions.”

While they continue to produce the still-effective Ditto 3D printers, their entire team is now composed of designers — and not a single engineer. The goal is to enable students to learn 3D printing by jumping on their program. Suyu said:

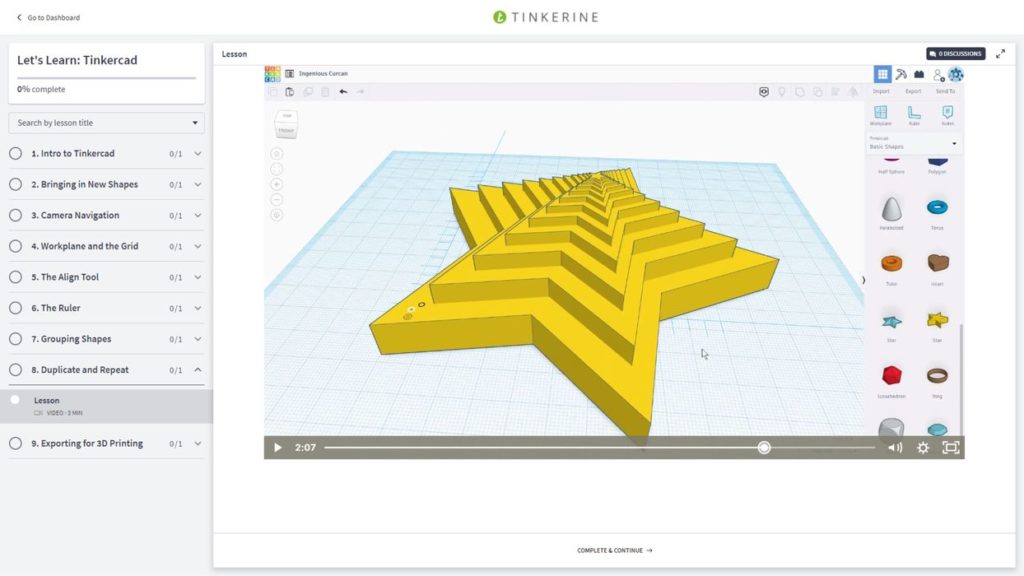

“CAD packages require specific types of workflows that people need to familiarize with. Some packages work better than others for some groups.”

Tinkerine Products

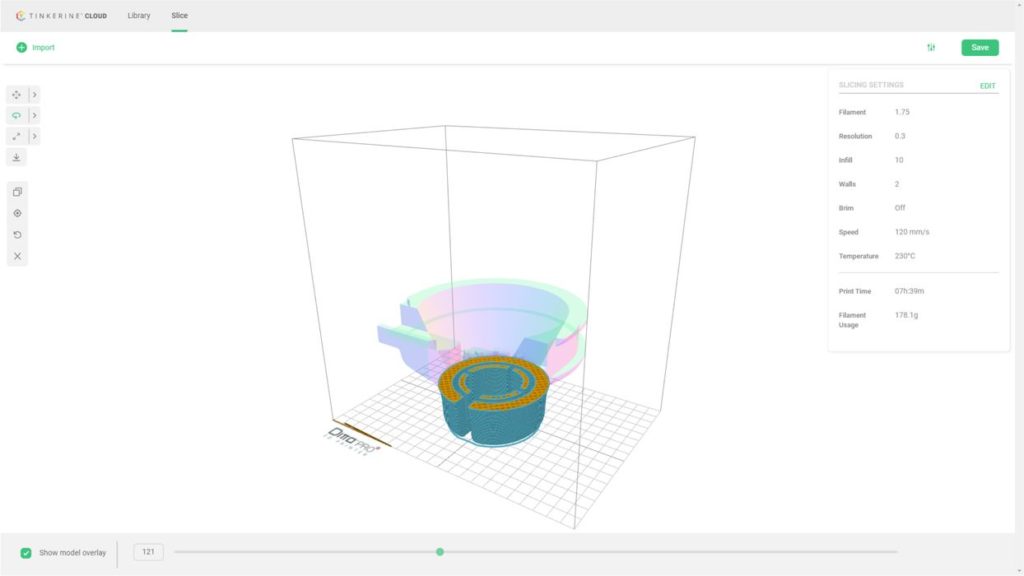

Their key products today are their extensive classroom tools, Tinkerine Skills Training, and Tinkerine Cloud. The company has spent considerable effort to simplify the work of preparing 3D print jobs and implemented this in their cloud system. Slicing a 3D model, for example, actually involves hundreds of mostly mysterious parameters, but they’ve managed to boil the puzzle down to only three basic parameters, with the rest being automated or integrated.

Tinkerine Cloud attempts to provide a content platform for leveraging complex 3D print applications. This includes design, modeling, slicing and printing.

Suyu believes most people using 3D printing simply want to get the job done, rather than “tinker” with the equipment and software. He said:

“The technology has to be invisible to allow focus on what really matters: the application.”

Unfortunately the majority can’t really learn much about the technology when they are just downloading and printing. Suyu said Tinkerine is trying to put students in the best position for future use of the technology:

“Later when they start a company they then have the skills to choose the right tools.”

Suyu explained that school districts want in-person training, as that is more effective for that industry. Tinkerine has learned a great deal about 3D print training over the many years they’ve been operating.

They found that while lower grades could accomplish educational goals using inexpensive FFF equipment, higher grade levels require expansion to more complex equipment using different 3D printing processes. However, they usually don’t have access to such equipment.

After eight years in the education market developing sophisticated 3D print training systems, they’ve now realized something important: SMEs also require the same kind of training.

During the pandemic many manufacturers have turned to 3D printing as a way to mitigate supply chain catastrophes, but many of them have basically no idea where to start. This is essentially the same problem that Tinkerine has solved with their skills platforms.

As a result of this realization, they’re now thinking of providing their systems to SMEs, with a mission to be a platform where people learn technology skills, design skills and all the required workflows.

This could be a huge opportunity for the company, as there are so many companies that don’t know what to buy or how to operate it if they did buy a machine. It’s also possible we may see Tinkerine partnering with other 3D printer manufacturers to assist them in making customers successful in 3D printing.

Via Tinkerine