ZMorph announced a new industrial 3D printer, the i500.

ZMorph is one of many 3D printer manufacturers based in Poland, and has been focusing on multi-tool desktop 3D printers for several years. Their most recent device, the FAB, includes not only a 3D printing toolhead, but also tools for CNC milling and laser engraving. Initially these machines were targeted at hobbyists and small workshops where it was difficult to place multiple machines.

However, in the past while ZMorph has been shifting to a more industrial market (and a new headquarters), as have several other 3D printer manufacturers. They explain:

“The company rebranded last year to focus on the industrial market and its R&D team has now developed a professional, high-performance 3D printer which responds to the most common problems the industrial 3D printing sector faces, with new features, all available at a reasonable price.”

It appears that the first fruits of that switch are with the all-new i500, a 3D printer utterly unlike their previous machines in many ways.

The i500 is a true industrial device, as it includes a number of features that should be attractive for manufacturers seeking an additive solution:

- Large build volume of 500 x 460 x 300 mm

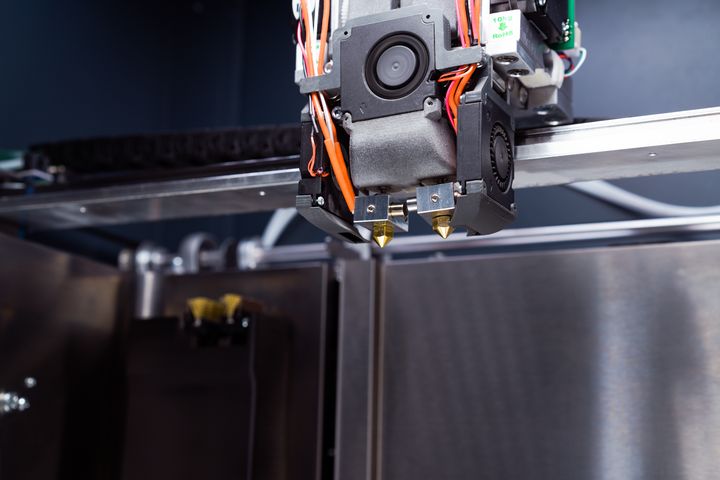

- Dual extruder enabling use of soluble support for complex prints

- Color touch panel for easier control

- Significant automation to simplify operator efforts

- A number of safety features, including auto-locking chamber door and fume filtration

- Hot end temperatures up to 300C

The large build chamber is a bit different. While most manufacturers seem to offer tall or cubic build volumes for their large-format devices, ZMorph has chosen a wide configuration. This seems to me to be the right choice for manufacturers, who have more surface area to lay out higher numbers of parts.

Another very interesting feature is the modular design of the i500. Apparently it’s possible to service the machine rapidly by detaching subassemblies for immediate replacement. This is quite different from most 3D printers, which require considerable effort to change some components.

Machine reliability is increased with a “Filament Flow System” that includes three sensors keeping watch on filament movement or absence.

The nozzle system is different from what you may see on many other dual-extrusion machines. For speed, two separate nozzles are used, and this eliminates the need to purge material when material changes occur on single-nozzle systems. However, two nozzles usually have issues because the “other” nozzle can sometimes bump into the print and cause a failure. This possibility is eliminated on the i500 because the “other” nozzle always lifts out of the way when it is inactivated.

By the way, the machine is available with 0.4 and 0.6mm nozzles, and ZMorph explains they are working on a 0.8mm nozzle for rapidly completing larger prints.

Materials are stored in a convenient drawer at the bottom of the unit.

The i500 should handle many engineering materials, as the hot end is quite capable and the build surface can be heated up to 130C. Combined with the heated build chamber, there should be little warping on i500 3D prints.

ZMorph explains the i500 is designed for 24-hour use, and judging by the features it certainly is. It’s pretty clear the ZMorph team spent considerable effort to identify the most common challenges facing industrial operators and solved them in the i500’s design.

Via ZMorph