Aiming to address the issue of plastic waste in the industry, starting with PLA.

uk

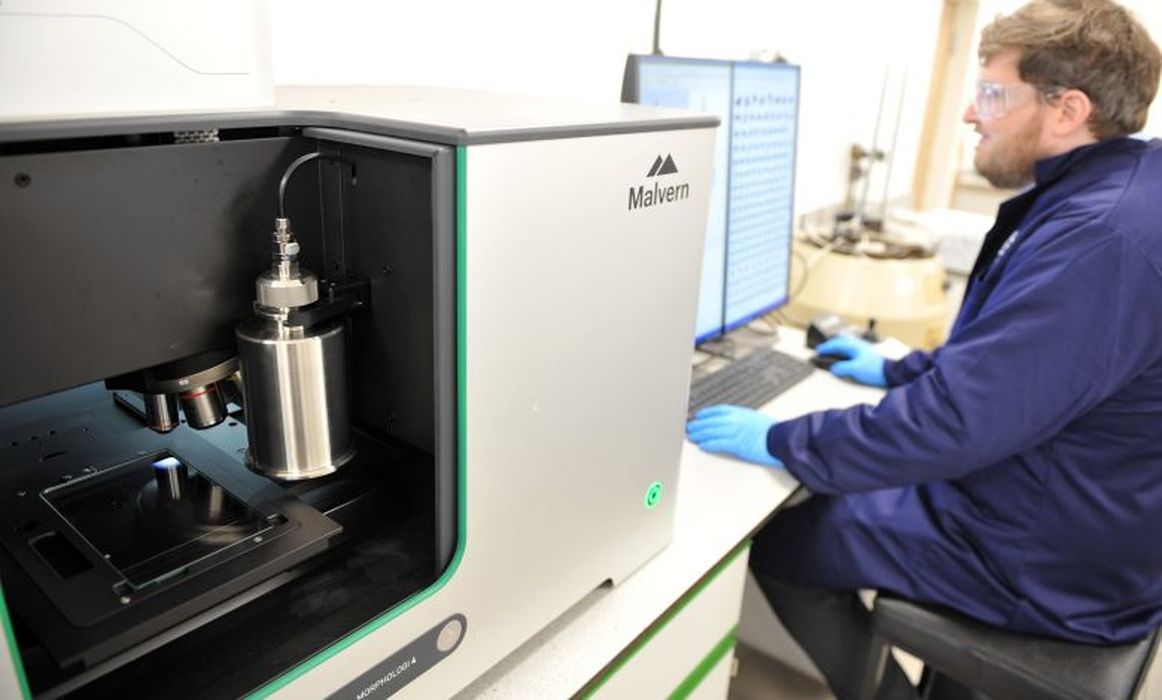

Materials Processing Institute Embarks on AI Initiative to Transform AM in the UK

Working with Additive Manufacturing Solutions Ltd and AMFG to develop SMART-APP tool for predictive material reuse.

UK Productivity and 3D Printing

Charles R. Goulding and Preeti Sulibhavi look at how 3D printing technology could assist the UK economy.

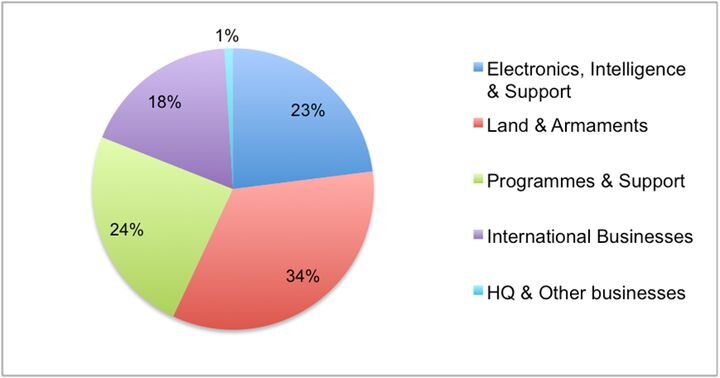

Large UK Defense Budget and 3D Printing

Charles R. Goulding looks at recent defense spending changes in the UK and how that may affect use of 3D printing.

Another PLA Recycling Venture

I’ve just noticed another PLA recycling service, specifically for 3D print waste.

HS2 Speeding Rail Construction Using 3D Printing

The UK’s high-speed rail project, HS2, will use advanced construction 3D printing.

Digital Manufacturing Centre Launches In The UK

The UK’s Digital Manufacturing Centre has officially opened.

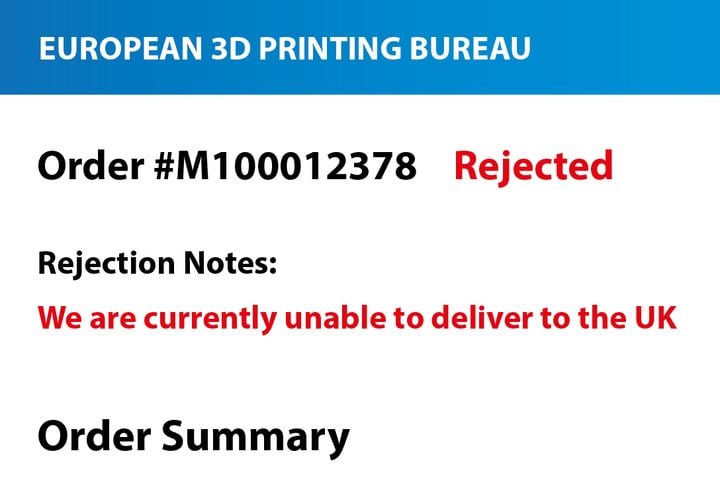

Brexit Slowly Reshapes The 3D Print Market

News from 3DPRINTUK tells a story of how Brexit is slowly reshaping the 3D printing world.

The UK’s Design For AM Network

There’s a meeting place for those working on methods for additive manufacturing design in the UK: the Design for AM Network.

Scotland Targets Boeing Supply Chain

Charles R. Goulding and Preeti Sulibhavi take a look at Scotland’s interesting moves in aerospace supply chain and potential impact on global 3D printing activity.

Not A Surprise: TCT 3Sixty 2020 Cancelled

In a move that could have been predicted, the organizers of TCT 3Sixty 2020 have decided to cancel the upcoming 3D printing event.

Brexit, BAE Systems, Renishaw and 3D Printing

Charles Goulding and Peter Favata look at a partnership between two UK-based 3D printing companies during Brexit.

Thoughts On TCT Show 2019

What happened at TCT Show 2019? We were there and provide an overview of our thoughts on this event.

The Regionality Of Major 3D Print Events

Every 3D printing / additive manufacturing trade show attracts a certain crowd, and it seems to differ by region. Why is this important?

What Will No-Deal Brexit Mean For 3D Printing?

The UK leaves the EU on October 31st. What might this mean for companies involved in 3D printing? We look at a long list of issues.