Some 3D prints require a long time to complete. In general, the rule of thumb is: The larger the print, the longer the print. But that doesn’t mean you can’t speed up the process.

If you’re looking to print out something that doesn’t necessarily require the greatest details, and time is of the essence, simply use a bigger nozzle. I’ve personally used a 0.4, 0.6, and 0.8mm nozzles and from my experience, as is expected, the larger the nozzle, the lesser the quality. However I’ve found that for my purposes, a 0.6mm nozzle gives me great quality at the fastest speed. A 0.6mm nozzle (at 0.36 layer height) is 4X faster than a 0.4mm nozzle (at 0.24 layer height).

Keep in mind however that the larger the nozzle, the more your extruder has to extrude to ‘keep up’ with the printer speed. Think of it this way: A 0.8mm nozzle has to extrude twice as fast as a 0.4mm nozzle at the same print speed. This in turn could cause your extruder to skip and not extrude properly. That’s why a print speed of 500mm/s is unheard of on a 0.8mm nozzle, but what big nozzles lack in speed, they make up for in volume.

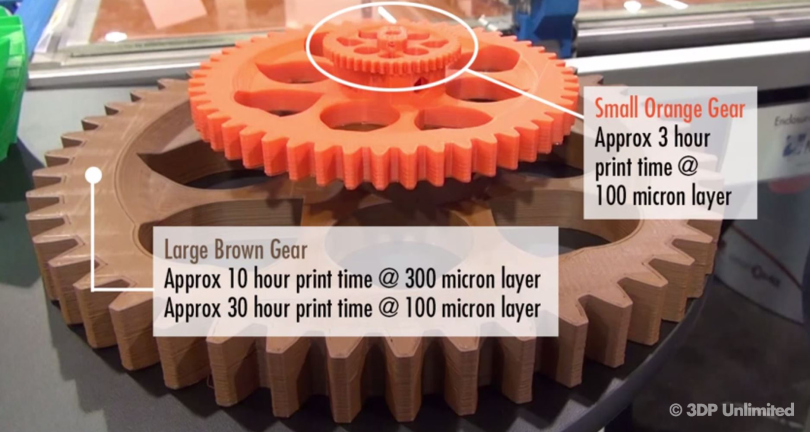

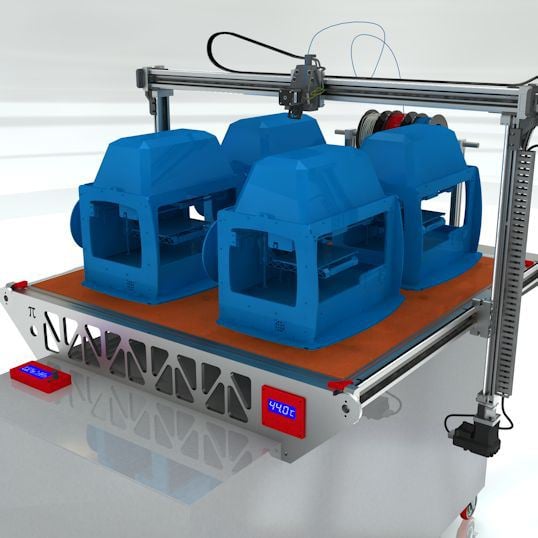

If you’re looking to buy a 3D printer that can create furniture or other large items, the 3DP1000 from 3DP Unlimited is exactly what you need!

It is one of the largest FDM printers in the market today. It can create objects up to 1 X 1 X 0.5 meters, and use a nozzle up to 1.2mm wide. The company has published a short video of how they use different nozzles to speed up printing at the link below.

But if buying a 3D printer for the price of a small car isn’t your thing, you can simply upgrade your RepRap 3D printer with a larger nozzle from a company like E3D, and start printing faster at a fraction of the price.

Via 3DP Unlimited

Fabbaloo correspondent & 3D Printing enthusiast Mike Difronzo – Founder WiZE 3D